What is a Dustbin Chute?

Cycling is renowned for its numerous health benefits, including improved cardiovascular fitness, muscle strength, and mental well-being. Vertical bicycles, with their comfortable and user-friendly design, can encourage more people to incorporate cycling into their daily routines. Whether commuting to work or taking a leisurely ride in the park, individuals can enjoy the physical activity while also experiencing the mental health benefits associated with being outdoors.

Advantages

gate valve knife type

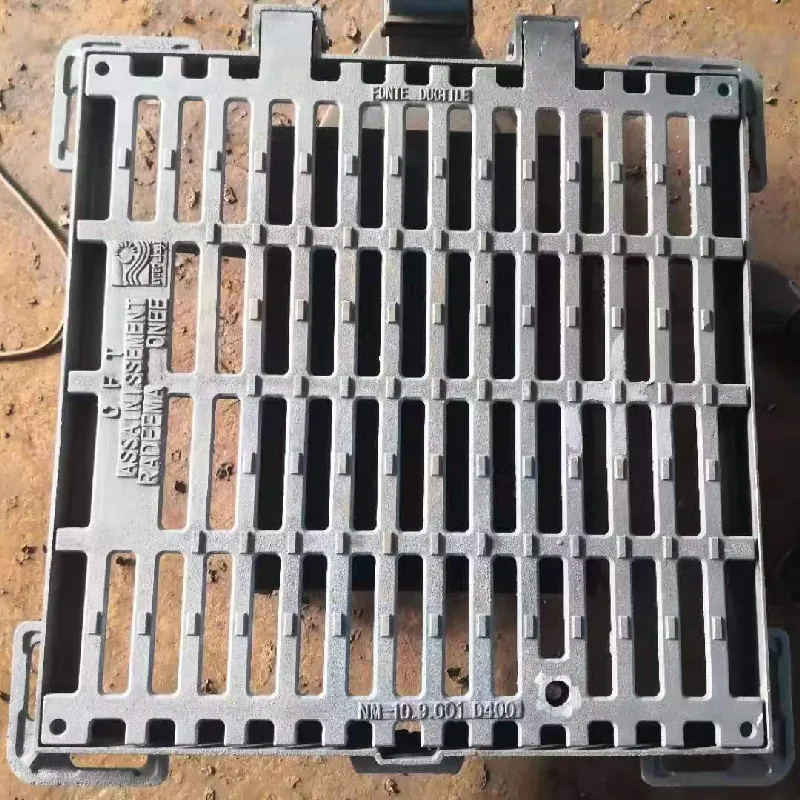

Understanding Gully Drain Covers Importance, Types, and Maintenance

In today's urban landscape, the need for effective traffic management and enhanced security has never been more crucial. One innovative solution that is gaining traction is the automatic bollard. These versatile barriers not only serve to control vehicle access but also offer a range of benefits that make them an ideal choice for various applications. As cities continue to develop and evolve, automatic bollards for sale are becoming increasingly popular, catering to a diverse array of needs and environments.

The Design of Manhole Covers

Exploring Footpath Bollards Functionality and Aesthetics in Urban Design

Types of Manhole

Round concrete drain covers enhance safety in urban settings. The round shape eliminates sharp edges, reducing the risk of injury to pedestrians and cyclists. Moreover, their weight and robust construction mean they are less likely to be dislodged or removed, minimizing the risk of accidental falls or vehicular damage. This is especially important in urban areas where the safety of both vehicles and people is a priority.

Small cycle stands can also have positive economic implications. They can attract businesses and tourists who appreciate and utilize cycling as a convenient form of transportation. Areas with readily available cycle stands may see increased foot traffic, benefiting local shops and eateries. Moreover, as more people opt for cycling, savings on fuel and car maintenance can redirect those funds into the local economy, enhancing overall community well-being.

Materials for manhole construction

5. Cost-Effectiveness While the initial investment in stainless steel repair clamps may be higher than clamps made from less durable materials, the long-term savings often outweigh the initial costs. Their longevity and low maintenance requirements mean fewer replacements over time, resulting in reduced operational expenses.

2. Gradient Efficiency The 6% slope ensures a rapid drainage rate, minimizing water accumulation. This gradient prevents the stagnation of water, which can lead to a host of problems, including erosion, water damage, and pest proliferation.

Conclusion

While horseshoe bollards offer various benefits, it's essential to consider maintenance aspects. Depending on the material used, some bollards may require more frequent upkeep than others. For example, metal bollards may necessitate regular painting or rust treatment, while concrete models might need periodic cleaning to remove dirt and debris. Choosing high-quality materials and finishes can mitigate these concerns and extend the lifespan of the bollards.

Conclusion

1. Inspection Periodically inspect the valve for signs of wear, corrosion, or leaks. Look for external damages like cracks in the body or flanges.

Investing in quality grating from reputable manufacturers can lead to safer working environments, enhanced operational efficiency, and significant long-term savings. As businesses look to improve their facilities, leveraging the expertise and products from grating manufacturers will undoubtedly prove beneficial in the long run.