Current location:maple veneer edge tape >>Text

maple veneer edge tape

Hebei Qiuzhuo door bottom noise seal123People have read

Introduction...

Tags:

Latest articles

maple veneer edge tape1. Protection for Your Floors

...

Read More

maple veneer edge tapeGiven their robust properties, FKM rubber sheets find applications in numerous fields. In the automotive industry, they are often used for gaskets, seals, and O-rings in engines and fuel systems. Their ability to resist high temperatures and harsh chemicals makes them ideal for high-performance vehicles and machinery.

...

Read More

maple veneer edge tapeWhile functionality and durability are paramount, aesthetics cannot be overlooked, especially in a home’s entryway. The first impression visitors get of your home comes as they step through the door, making it essential that this space is inviting. Purrugs offers a variety of designs, colors, and patterns that cater to different tastes and home styles. Whether you prefer a classic, understated look or something more vibrant and trendy, there’s likely a Purrugs mat that fits the bill.

...

Read More

Popular articles

Weather Resistance

- Adhesive grip pads are a versatile and practical solution for a variety of home and office needs. These pads are designed to provide a strong grip on surfaces, preventing items from slipping or sliding. From keeping rugs in place to securing picture frames on walls, adhesive grip pads offer a simple and effective way to keep things in their proper place.

The Benefits of Diatom Mud Floor Mats

When it comes to home improvement and maintaining a comfortable living environment, many homeowners overlook the significance of small features, such as the bottom strip for doors. Often referred to as door sweeps or door bottoms, these strips play a vital role in enhancing the functionality and aesthetics of a door. In this article, we will explore the various benefits of installing a bottom strip for doors and why it should be on your home improvement checklist.

Conclusion

Durability and Weather Resistance

Latest articles

-

Conclusion

-

Understanding MDF Edge Tape A Key Component in Furniture and Interior Design

-

Conclusion

-

Wet Step Mats are specially designed to provide maximum traction and grip on wet and slippery surfaces. These mats are made from high-quality materials that are water-resistant and are able to effectively drain liquids away from the surface, keeping the area safe and dry. Whether you are walking in a restaurant kitchen, bathroom, pool area, or any other location where water is present, Wet Step Mats are the perfect solution to prevent accidents and ensure the safety of everyone.

-

4. Accumulation of Grease and Food Particles This can lead to a reduced seal effectiveness over time.

-

Conclusion

Links

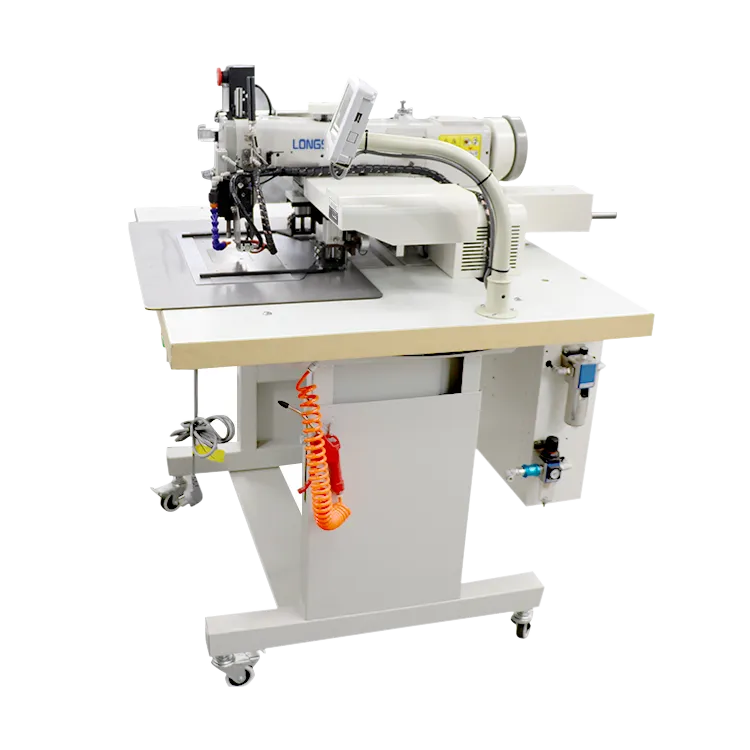

Despite their numerous advantages, the transition to CNC upholstery sewing machines can present challenges. The initial investment in high-quality CNC machines can be substantial, making it a significant consideration for smaller companies. Furthermore, the integration of advanced technology into existing workflows may require retraining staff, which can be met with resistance. Businesses must weigh the long-term benefits against these initial hurdles to determine if CNC technology is the right fit for their operations.

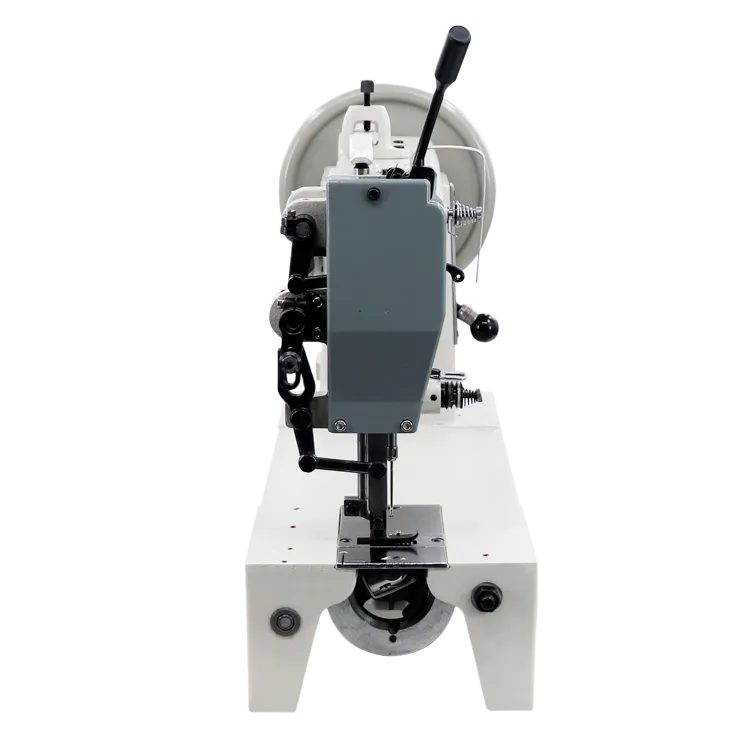

The single needle edge cutter machine also minimizes material waste. With precision cutting, manufacturers can optimize the use of fabric, ensuring that less material is discarded. This aspect of the machine is particularly beneficial in an era where sustainability and cost-effectiveness are critical considerations for textile companies.

Typically, the machine head employs methods such as stitching, heat sealing, or gluing to close the bags. Each method has its advantages depending on the type of bag and the contents that need protection. For example, heat sealing is particularly effective for plastic bags as it provides a strong and waterproof closure. On the other hand, stitching is suitable for fabric bags, delivering durability and resistance against tearing during transport.

The high-speed single needle lockstitch sewing machine operates using a simple yet effective mechanism. It utilizes a single needle that passes through the fabric layers, forming a lockstitch by interlocking the upper thread with the lower thread supplied from the bobbin. This design not only ensures durability and strength in the seams but also allows for a wide range of stitches, from basic straight stitches to more complex patterns.

- Despite advancements in technology, the single lockstitch machine remains a staple in workshops and factories worldwide. Modern versions, equipped with computerized controls and advanced features, have enhanced precision and productivity even further. However, the core principle of the lockstitch remains unchanged, a testament to the genius of Howe's original design.

4. Compatibility with Machines Lock sewing can be easily executed on standard sewing machines, making it accessible for home sewers. The simplicity of the technique allows for a smooth sewing experience.

Choosing the right sewing machine for upholstery can significantly affect your crafting experience and results. It is essential to prioritize features such as heavy-duty construction, powerful motors, and specialized attachments like walking feet. With a range of options available, from budget models to professional-grade machines, you're sure to find one that fits your needs. Whether you are a beginner or a seasoned upholstery enthusiast, the right tool can make your sewing projects more enjoyable and successful. Happy sewing!

Moreover, advanced bag making machines include features such as automation and digital controls, which enhance efficiency and reduce labor costs. Automated processes minimize the need for manual intervention, allowing for high-speed production and consistent quality. Digital controls enable manufacturers to quickly adjust settings for different bag specifications, which reduces setup times and increases operational efficiency.

Conclusion

Factors Influencing Price

Heavy-duty sewing has emerged as a vital skill, especially for those who work with tough materials, whether in crafting, home décor, or industrial applications. This specialized form of sewing involves the use of robust equipment and techniques designed to handle thicker fabrics such as canvas, denim, leather, and certain synthetic materials. In this article, we will explore the essentials of heavy-duty sewing, including equipment selection, techniques, and tips for achieving professional-grade results.

A multi-needle quilting machine is designed with multiple needles, allowing the user to stitch various designs and patterns simultaneously. This feature significantly increases productivity, as it enables quilters to create intricate designs without the need to frequently change threads or needles. Most multi-needle machines come equipped with a wide range of built-in designs, fonts, and the capability to import custom patterns, making them versatile tools in any quilter’s arsenal.

- Overall, purchasing a used upholstery sewing machine can be a smart investment for anyone looking to take their upholstery skills to the next level. With a little research and some careful inspection, you can find a high-quality machine that will help you tackle any upholstery project with ease. So why wait? Start browsing for used upholstery sewing machines for sale today and take your upholstery skills to new heights.

The versatility of the modern chain stitch machine is evident in its applications across various sectors. In the garment industry, it is widely used for sewing stretch fabrics and intricate designs, allowing for more intricate patterns without sacrificing quality. Moreover, the machine can be customized with different needle sizes and thread types, further expanding its range of capabilities. This adaptability not only meets the demands of contemporary fashion but also supports innovative design techniques, pushing the boundaries of creative expression in textile production.

The applications of the double needle sewing machine are extensive, particularly in the fashion industry. It is commonly used to sew hems, create decorative topstitching, and construct seams on garments. The parallel stitching it produces not only enhances the aesthetic appeal of clothing but also adds a layer of strength to seams, making them more resistant to wear and tear.

double machine silai machine

The applications of the Dressmaker Zig Zag Sewing Machine are vast. From garment construction to quilting, home decor, and crafting, this machine can tackle a wide range of projects. The ability to sew stretch fabrics, such as knits, with ease has made the zigzag stitch particularly popular among those making activewear or fitted garments.

5. Where to Buy

2. Enhanced Creativity With two needles, sewers can experiment with different thread colors and stitch patterns, providing opportunities for creative expression. For instance, one needle can use a decorative thread while the other handles the base, resulting in stunning visual effects.

4. Durability and Performance A well-constructed precision zigzag sewing machine is built to withstand the rigors of frequent use. High-quality components and smooth operation ensure that users can rely on their machine for years to come, whether they’re fabricating clothing, home décor, or crafting gifts.

When it comes to sewing projects that involve heavy materials like canvas, having the right tools can make all the difference. Among these tools, heavy duty handheld sewing machines have gained popularity due to their convenience and efficiency. These portable machines are particularly suited for a wide array of heavy-duty tasks, ranging from crafting outdoor gear to making home décor items.

4. Manufacturer Websites Many leading sewing machine manufacturers, like Brother and Singer, offer self-threading models. Visiting their websites can provide detailed information and direct links to purchase.

Heavy duty machines come with more robust standard attachments for tasks like hemming, ruffling, and binding on heavy fabrics. There are often additional attachments available like piping feet and binding folders to expand the abilities on heavy materials. Dual large spool pins allow quick and easy thread spool changes for continuous operation.

1. Sewing Machines Typically used in industries such as textiles and food packaging, bag sewing machines utilize industrial threads to stitch bag tops securely. This method is particularly effective for multi-wall paper bags, as well as woven polypropylene bags. The durability of the sewn closure makes it a preferred choice for heavy or bulk products.

bag closing machinery

Performance and Efficiency

The Synergy Between Coverstitch and Overlock Machines