Current location:wind stopper under door >>Text

wind stopper under door

Hebei Qiuzhuo door bottom noise seal5People have read

Introduction...

Latest articles

wind stopper under doorПри установке резиновых уплотнителей также важно следовать рекомендациям производителей. Неправильная установка может привести к утечкам и другим проблемам, которые могут значительно снизить эффективность уплотнителя. В некоторых случаях лучше всего доверить установку специалистам, чтобы гарантировать правильное и качественное выполнение работы.

...

Read More

wind stopper under doorIn today's fast-paced industrial and commercial landscape, protective solutions are more essential than ever. Among the numerous options available, rubber edge protectors stand out as a versatile and effective choice for safeguarding various surfaces and edges. These products not only enhance safety but also prolong the lifespan of equipment and fixtures across multiple applications.

...

Read More

wind stopper under door5 x 7 비슬립 러그 패드의 중요성

...

Read More

Popular articles

Safety for Corners of Tables Ensuring a Secure Environment

Eco-Friendly Options

Why Pickup Truck Mats Matter

Der er også miljømæssige fordele ved at vælge gummimåtter. Mange producenter fokuserer på at bruge genanvendte materialer, hvilket gør dem til et mere bæredygtigt valg. Dette tiltaler mange forbrugere, der ønsker at gøre deres del for miljøet.

Easy Maintenance

Un’altra opzione è rappresentata dalle soglie più alte, che possono essere installate per coprire lo spazio sotto la porta. Queste soglie possono non solo migliorare l’isolamento, ma anche contribuire a una maggiore sicurezza contro intrusioni. Tuttavia, l’installazione di una soglia può richiedere l’intervento di un professionista, a seconda della complessità del lavoro.

Latest articles

-

As sustainability becomes an increasingly important consideration for consumers, many brands now offer eco-friendly bath mats. Choose mats made from organic cotton or recycled materials to promote environmental health while enjoying a stylish accessory in your bathroom.

-

Conclusion

-

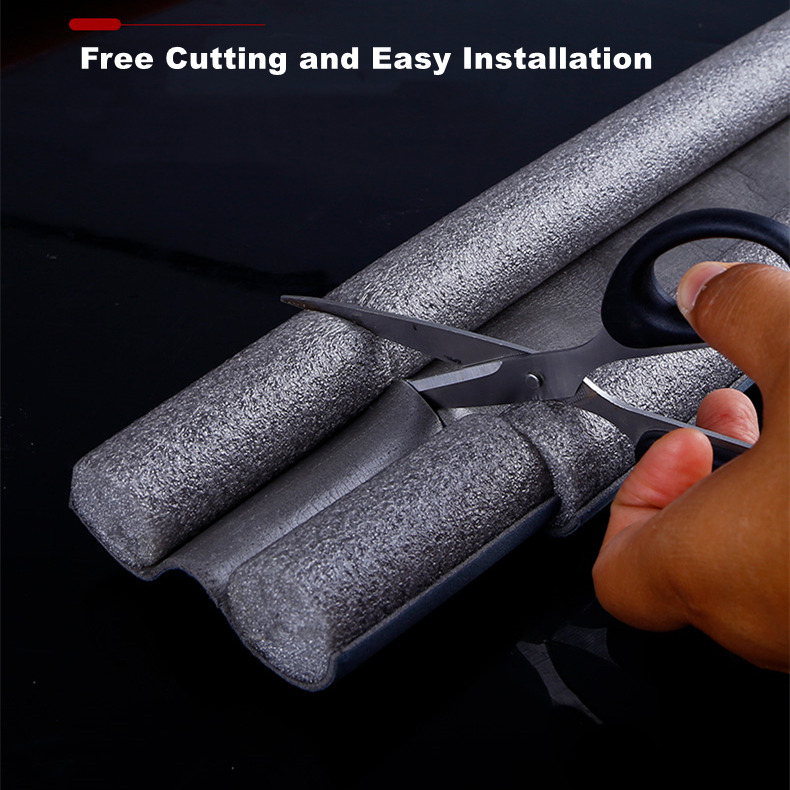

Installing a bottom door air blocker is a straightforward process that can be done by most homeowners without the need for professional assistance. The first step is to measure the width of the door and cut the blocker to the appropriate length. Next, simply slide the blocker under the door and adjust it as needed to ensure a tight seal.

-

In the world of digital photography, post-processing techniques play a crucial role in enhancing the visual appeal of an image. One such technique that has gained popularity among photographers is known as d weather stripping. This term may sound enigmatic to the uninitiated, but it essentially refers to the process of removing unwanted weather elements from a photo, such as fog, haze, or even blemishes on the sky.

-

There are several types of rain guards available on the market. Some are designed to be installed as part of a door sweep, which includes additional features like brushes or flexible strips to form a tight seal at the bottom. Others are standalone units that are affixed to the existing door. Innovations have even led to the development of adjustable or retractable models, which offer versatility depending on the season or weather conditions. With various options available, homeowners can select a product that best meets their aesthetic and functional needs.

-

Security is another crucial aspect of door sealing. A tight seal created with reliable adhesive can deter unauthorized access and prevent intruders from exploiting gaps in doorways. For businesses that handle sensitive information or valuable assets, investing in high-quality rubber door seal adhesives can add an extra layer of protection against theft and break-ins.

Links

Understanding the Basics of High Pressure Vertical Pumps

4. Suction and Discharge Flanges

Types:

By continuously increasing investment in new product research and development, as well as product upgrades , MineMaxx aim to further enhance the technical reserves of new ceramic desulfurization pumps and effectively extend their service life. In response to the current high wear and corrosion working environment in the desulfurization market, MineMaxx has completed the technical reserve work for more than 10 new ceramic desulfurization pumps, produced 2 complete machines, and fully provided customers with higher quality and more innovative products and services, saving user product spare parts procurement costs, improving user economic benefits, and providing strong support for subsequent market breakthroughs. Recently, the MM700D-A90 ceramic desulfurization pump has been successfully delivered to a user site in Inner Mongolia.

5. Seals

Materials: Made from wear-resistant materials like high-chrome alloys or stainless steel.

Materials: Made from wear-resistant materials like high-chrome alloys or stainless steel.

- Type of Slurry: Determine if the slurry is abrasive, corrosive, or contains large particles.

Monitoring and Maintaining AH Slurry Pump Parts

In addition to its shape and size, the material used for the volute's construction is also important. Typically, materials such as cast iron, stainless steel, or thermoplastics are employed, chosen based on factors like fluid characteristics, temperature, and pressure. For example, corrosive fluids may necessitate the use of more durable materials to prevent degradation and ensure longevity.

Reducing operational costs is a top priority in mining and quarrying, where the cost of equipment maintenance and energy consumption can significantly impact profitability. The efficient operation of horizontal slurry pumps plays a key role in achieving cost savings. By selecting the right centrifugal pump for slurry and maintaining it with AH slurry pump parts, operators can optimize energy use, reduce wear on pump components, and minimize the need for costly repairs. The long-term benefits of efficient slurry pump operation include lower energy bills, reduced maintenance costs, and improved overall efficiency in mining and quarry processes.

Efficient Horizontal Slurry Pumps Transport in Mining Operations

- Volute Liners: Protect the pump casing in the volute section.

Monitoring and Maintaining AH Slurry Pump Parts

a. Sealing Mechanisms:

- Many manufacturers offer software tools that automate the pump selection process.

Enhancing Durability with High Pressure Vertical Pumps

- Many manufacturers offer software tools that automate the pump selection process.

Slurry pump parts are particularly susceptible to wear due to the abrasive nature of the materials they handle. Components such as the impeller, casing, and liners are all subject to gradual wear, which can impact pump performance if not managed properly. Regular inspections and wear assessments are key to determining the optimal replacement cycle for these parts. By using advanced monitoring techniques and predictive maintenance tools, you can track the wear rate of slurry pump parts and plan replacements before they cause a significant drop in performance. This proactive approach helps to extend the life of the pump and reduce overall maintenance costs.

2. Pump Casing

Expand product application areas and shorten the conversion cycle of new product contracts. With the successful development of the company's first 300FMM-B90 froth slurry pump, combined with the results of market research, so far, MineMaxx has again completed the technical reserve of three new products of froth slurry pump, and completed the design of 65MZJ froth slurry pump, realizing the full coverage of conventional pump types. Recently, MineMaxx signed a contract with a company in Hangzhou for two sets of 100FZJ-B50 froth slurry pumps. The products involved in the contract are the new products of the company's technical reserve project. After receiving the contract, the relevant departments of the company quickly carried out work, and completed the technical transformation of all new product contracts in only three days, providing strong technical support for the delivery of subsequent new product contracts.

Evaluating Slurry Transport Using Centrifugal Pumps

In quarrying, the separation of sand and gravel is a vital process that requires reliable equipment. Horizontal slurry pumps are particularly well-suited for this task, as they can efficiently handle the slurry mixture of sand, gravel, and water. The centrifugal slurry pump design ensures that these materials are separated and transported to their respective storage or processing areas with minimal energy consumption. By utilizing OEM horizontal slurry pumps, quarry operations can streamline their processes, reduce operational costs, and improve the quality of the final product. The durability and efficiency of these pumps make them a cost-effective solution for handling the abrasive and coarse materials commonly found in quarries.

The Compact Footprint of Vertical Multistage Centrifugal Pumps

2. Use a Selection Chart or Software

One of the main advantages of propeller pumps is their simplicity and durability. Given their straightforward design, maintenance requirements are generally low, which is advantageous for organizations looking to minimize operational costs. Furthermore, these pumps can be made from various materials designed to resist corrosion, extending their lifespan even in harsh environments.

Maintenance of sewage pump impellers is also vital for ensuring their longevity and functionality. Regular inspection can help identify wear or damage, and timely replacement of worn-out impellers can prevent pump failures and costly repairs. Moreover, keeping the impeller clean from debris buildup ensures optimal performance.

Understanding the components of the wet end of a slurry pump is vital for anyone involved in industries that rely on such equipment. Proper maintenance and selection of high-quality parts can significantly enhance the efficiency and lifespan of a slurry pump, reducing operational costs and minimizing downtime. By focusing on the critical wet end parts—impeller, casing, wear plates, flanges, and the shaft assembly—operators can ensure their pumps perform reliably in challenging environments.

- Consider the type of seal (e.g., mechanical seals, packing) based on the slurry's properties and operating conditions.

In line vertical pumps are specifically designed to save space while delivering efficient performance. These pumps are installed directly in the pipeline, with the motor positioned vertically, reducing the overall footprint of the pump system. This design is particularly beneficial in applications where space is limited, but high performance is still required. In line vertical pumps are commonly used in HVAC systems, water treatment plants, and other industries where compact, efficient pumping solutions are needed. The vertical orientation of these pumps also allows for easier alignment and installation, which can reduce the time and cost associated with setting up a pump system.

Assessing Wear in Slurry Pump Parts

5. Shaft and Bearing Assembly

Wear Factors: Bearings can wear out due to the mechanical loads and need periodic lubrication and replacement.