In conclusion, yellow electrical tape is more than just a simple tool in an electrician's kit. Its multifunctional nature, spanning wire color-coding, insulation, temporary marking, and safety signaling, makes it an indispensable asset in electrical work. Whether you are a seasoned electrician or an enthusiastic DIYer, utilizing yellow electrical tape can enhance the safety, efficiency, and organization of any electrical project. Always remember that while tape can serve many roles, proper installation and adherence to safety standards are paramount in ensuring that all electrical work is conducted safely and effectively.

Butyl tape really is an all-rounder tape! It is perfect for use in the marine industry because of its strength, waterproof seal and compatibility with boat surfaces. Use butyl tape for boat hatches, portlights, and deck fittings.

Final thoughts

Applications for Butyl Rubber Sealant Tape

The Versatility of Black PVC Electrical Tape

varnished cambric tape uses.

Self-Fusing Silicone Repair Tape: What You Need to Know!

adhesive rubber seal strip. Refrigerators, ovens, and washing machines, among others, utilize these strips to ensure airtight seals, preserving food freshness, optimizing energy consumption, and preventing water leakage.

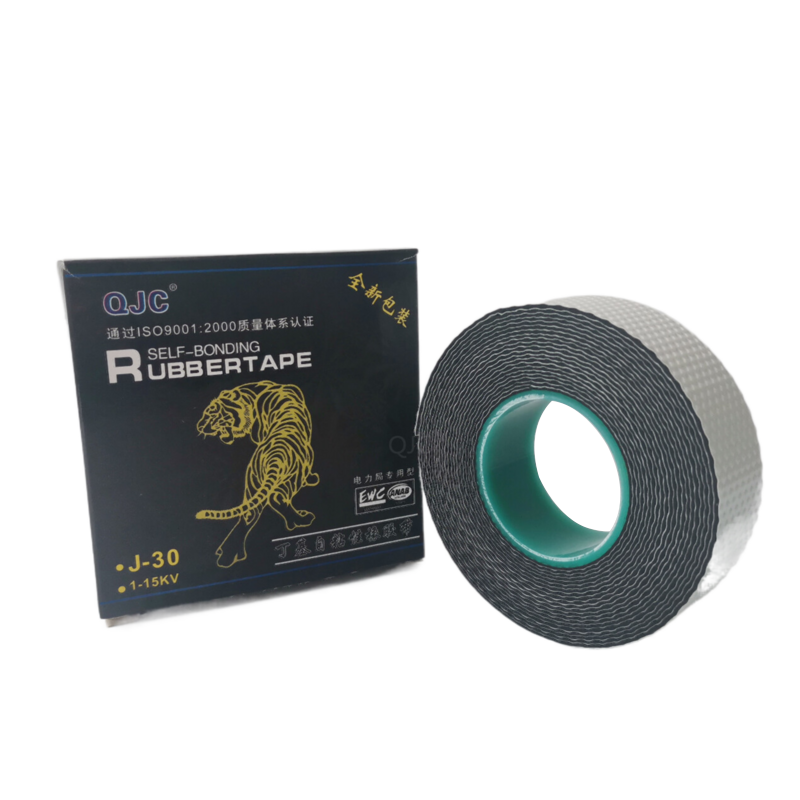

adhesive rubber seal strip. Refrigerators, ovens, and washing machines, among others, utilize these strips to ensure airtight seals, preserving food freshness, optimizing energy consumption, and preventing water leakage.In this post, we'll briefly explain why you would use a self-fusing electrical tape and the typical applications for them.

flex tape black 4 in x 5 ft. Press down firmly to ensure a secure bond, and your repair is complete. There is no need for messy adhesives, complicated tools, or drying time – Flex Tape Black provides a quick and reliable solution to your repair needs.

2. Temperature Resistance High voltage installations often experience considerable heat. Insulation tape must be capable of operating under high temperatures while maintaining its insulating properties. Materials like PVC, silicone, and various rubber composites are commonly used for their heat-resistant qualities.

high voltage busbar insulation tape

Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets

Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals

This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals