For many bearings, a good bearing seal is essential. Bearing seals perform a dual function by keeping lubricants from leaking out while preventing impurities from entering your parts. Both procedures can help your bearings last longer, but choosing the proper seals for your components is critical. Different types of bearing seals include:

Scrape off all the traces of dirt and old gasket from the engine and sump flanges with a paint scraper.

Oil seals increasingly had to meet higher requirements, which is why PTFE was developed in 1980. This variant can better withstand higher engine speeds, higher oil temperatures, longer oil intervals and modern lubricants. In addition, the oil seal contains a wider contact surface, which ensures less wear.

(hydrodynamic ribs)

• Rotational speed

• Oil viscosity, etc.

Minor lip The minor lip prevents the entry of dust and contaminants from outside.

Lubricant can be retained in the space between the main lip and the minor lip.

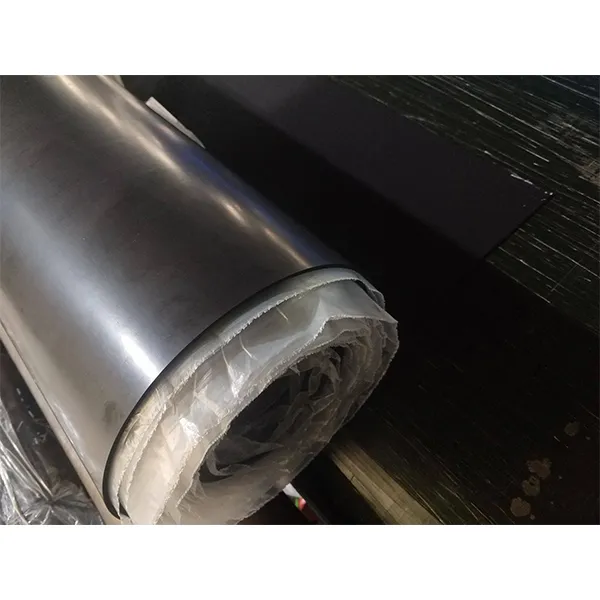

Shaft seals, dirt seals, grease seals, lip seals, and many other names are only a few of the many names given to oil seals. They are simple components used in rotary shaft machinery to keep oil from leaking and impurities like dust, dirt, and water out. However, an oil seal’s most crucial role is to safeguard all ball, sleeve, and roller bearing types found in rotating shafts. Additionally, the seals stop blending two fluids that shouldn’t mix, such as water and oil.

Oil seal installation

What are Oil Seals – A guide to Oil and Rotary Shaft Seals