Finally, the selection of gate valves should align with specific operational requirements and safety standards. Engineers often evaluate factors such as pressure ratings, temperature tolerances, and compatibility with the transported fluids to ensure the right choice is made. Furthermore, proper installation techniques and adherence to best practices are vital for maximizing the efficiency and effectiveness of gate valves in pipeline applications.

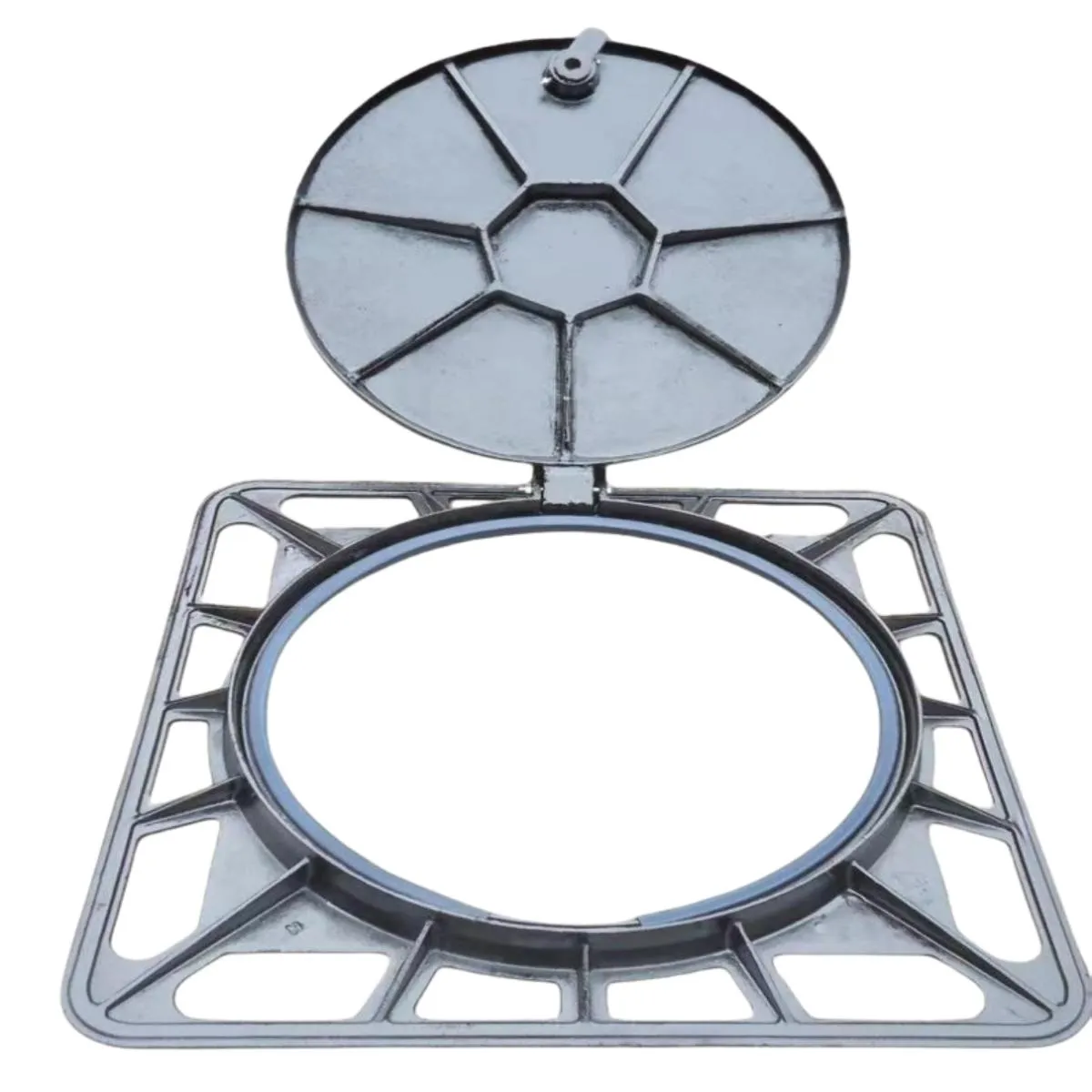

The journey down a manhole may seem daunting to some, but it presents a unique opportunity for exploration and understanding. Each step down into the darkness can transport one into a different realm, where the hustle and bustle of urban life gives way to the quiet hum of machinery and the gentle flow of water. The descent often begins with a sturdy metal ladder, its rungs worn smooth by countless journeys over the years. As one descends, a sense of curiosity mingles with apprehension, stirring thoughts about the history of the city and the unseen forces at work beneath our feet.

2. Inspection Before lapping, it is vital to inspect the sealing surfaces for any major defects. This includes checking for pitting, scratching, or any other signs of damage that might require repair or replacement.

gate valve lapping

Moreover, the uniform shape allows for easier installation and removal. A round manhole cover can be easily rolled in and out of place, making maintenance more efficient for utility workers. This efficiency is crucial for minimizing traffic disruptions during repair or inspection work.

In addition to their practical benefits, round recessed manhole covers can enhance the visual appeal of urban environments

. Recessed designs, which are often created to blend into the surrounding pavement, can be paired with decorative patterns or engravings. This allows municipalities to introduce branding elements or artistic designs into public spaces, transforming a functional object into a piece of urban art.4. Corrosion Resistance Given the often-harsh conditions of mining environments, step irons should have a protective coating or be made from corrosion-resistant materials to extend their lifespan.

After the initial installation, ongoing maintenance is another critical consideration. Automatic bollards require regular maintenance to function properly and remain durable under various weather conditions. This maintenance can include routine checks, cleaning, or more extensive repairs if a malfunction occurs. Some manufacturers offer maintenance contracts, which can be beneficial for budgeting future expenses but can also add to the ongoing costs.

3. Bar Spacing and Thickness The spacing between the bars is another critical factor. Standard spacing is usually around 1 inch, but this can vary based on the intended use. The thickness of the bars also contributes to the overall strength of the grating. Thicker bars enhance load-bearing capabilities but may add to the weight and cost.