Current location:weather stripping silicone door seal strip door >>Text

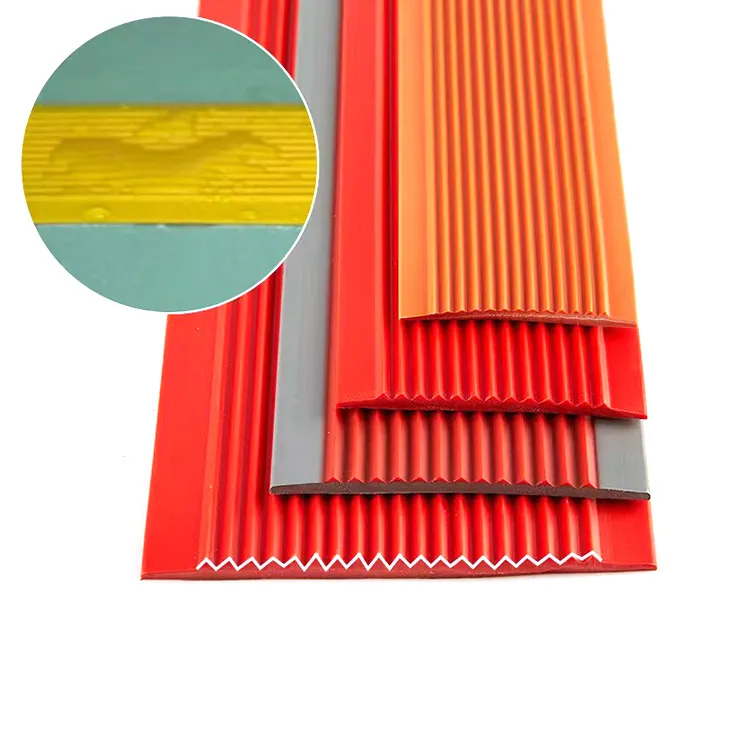

weather stripping silicone door seal strip door

Hebei Qiuzhuo door bottom noise seal642People have read

Introduction...

Latest articles

weather stripping silicone door seal strip doorSafety Matters

...

Read More

weather stripping silicone door seal strip doorExternal door bottom draught excluders are valuable additions to any home. Not only do they offer energy savings and enhance indoor comfort, but they also promote a healthier living environment and require minimal upkeep. With their easy installation and available aesthetics, they are a smart investment for homeowners looking to improve their living spaces. As we strive for comfort and sustainability in our homes, these simple devices prove that good things often come in small packages. Investing in draught excluders could be one of the most effective ways to reduce energy waste and improve the quality of life at home.

...

Read More

weather stripping silicone door seal strip doorConclusion

...

Read More

Popular articles

1. Purchase the Right Door Sweep Choose a door sweep that matches your door style (there are options for both interior and exterior doors).

Stairs can be one of the most dangerous parts of a home, especially for children, the elderly, and anyone with mobility issues. The risk of slipping and falling on stairs can lead to serious injuries, making it essential to take preventive measures. One effective solution is the use of non-skid pads for stairs. These pads provide traction, enhance safety, and contribute to a peace of mind for residents and visitors alike.

Installation Tips

Noise Reduction

How to Fix the Seal on an Oven Door

The Benefits of Self-Adhesive Edge Banding Tape

Latest articles

-

Another significant advantage of rubber floor strips is their ease of installation. They can be easily cut to size and adhered to the floor without the need for professional help. Many homeowners appreciate this feature, as it saves both time and money. Furthermore, maintenance is a breeze. Rubber strips can be easily cleaned with a broom or mop, and if they become damaged, individual strips can be replaced without having to redo the entire floor.

-

Comfort Underfoot

-

For those who want to take a more permanent approach, replacing the bottom rail of the door can be an effective solution. This process may involve some level of DIY skill, but it can be much more effective than temporary fixes. A new bottom rail can create a tighter seal and prevent air from escaping or infiltrating.

-

5. Self-Adhesive Foam Seals

-

Understanding the Impact of Airflow

-

The Importance of an Outside Door Bottom Seal

Links

ERIKS also supplies the types GR and GRST. These are virtually identical to the types R and RST, except in this case the metal inner ring is also completely encased in rubber. ERIKS uses FKM rubber here as standard, so these seals are ideal for use in acidic environments.

Finally, consider the size and shape of the gasket, as well as any specific design requirements that may impact the gasket's performance. Custom-made natural rubber gaskets can be designed to meet the unique needs of your application, ensuring a precise fit and optimal sealing performance.

In addition to withstanding high pressures, oil seals must also be able to withstand the harsh conditions often found in industrial settings. This includes exposure to oil, chemicals, heat, and vibration, which can all contribute to the degradation of the seal over time. Proper selection of materials and regular maintenance are essential for ensuring the longevity and reliability of high-pressure oil seals.

The seal shown in Fig. 14.2 is a relatively simple design; most automotive seals are more complex. Dust lips are often used to keep outside contaminants away from the oil lip seals; such seals thus have undercuts that make demolding more difficult. Fluoroelastomer compounds used for such undercut shapes must have reasonably high elongation at break at molding temperatures to avoid tearing the part during demolding. The metal insert is often U-shaped, and stock may be molded to form a thin layer over the outside of the insert. Since both compression and injection molding methods are used, suppliers of fluoroelastomers for shaft-seal applications often must provide different versions of the same polymer composition-medium to high viscosity for compression molding, and low to medium viscosity for injection molding. Different precompounds may be necessary to accommodate relatively long compression-molding times at low temperature and very short injection-molding times at high temperature.

Multiple materials and compounds are used to make oil seals. Some of the oldest materials still used today include felt and leather compounds. However, the trend in mass production has experienced a shift towards synthetic elastomers or rubber.

Oil seals can show good sealing performance in combination with properly designed shafts and housings.

Oil seals are widely used as sealing devices for machines.

JTEKT's oil seals are described in our catalog, Oil Seals & O-Rings.

However, the catalog uses a large number of technical terms and is very long, so many people seem to have trouble handling it.

Therefore, this series of columns will summarize the following in order:

• The structure, functions, and types of oil seals

• How to select the right oil seal

• Handling of seals, and causes and countermeasures for oil seal failure

In hydraulic systems, they safeguard against contamination and loss of hydraulic fluid, thereby enhancing system efficiency and reliability In hydraulic systems, they safeguard against contamination and loss of hydraulic fluid, thereby enhancing system efficiency and reliability

In hydraulic systems, they safeguard against contamination and loss of hydraulic fluid, thereby enhancing system efficiency and reliability In hydraulic systems, they safeguard against contamination and loss of hydraulic fluid, thereby enhancing system efficiency and reliability oil seal rubber part.

oil seal rubber part.A: with minor lip