Current location:drainage mat for roof >>Text

drainage mat for roof

Hebei Qiuzhuo door bottom noise seal2158People have read

Introduction...

Tags:

Latest articles

drainage mat for roofAutomotive door seals, often overlooked components in vehicle design, play a crucial role in enhancing the overall performance, comfort, and safety of passenger vehicles. These seals, typically made from rubber or foam materials, are designed to provide a tight barrier between the vehicle's body and its doors. Understanding the significance of door seals can shed light on how they contribute to a superior driving experience.

...

Read More

drainage mat for roofUnderstanding the Problem

...

Read More

drainage mat for roofUnderstanding the Under Door Odor Blocker

...

Read More

Popular articles

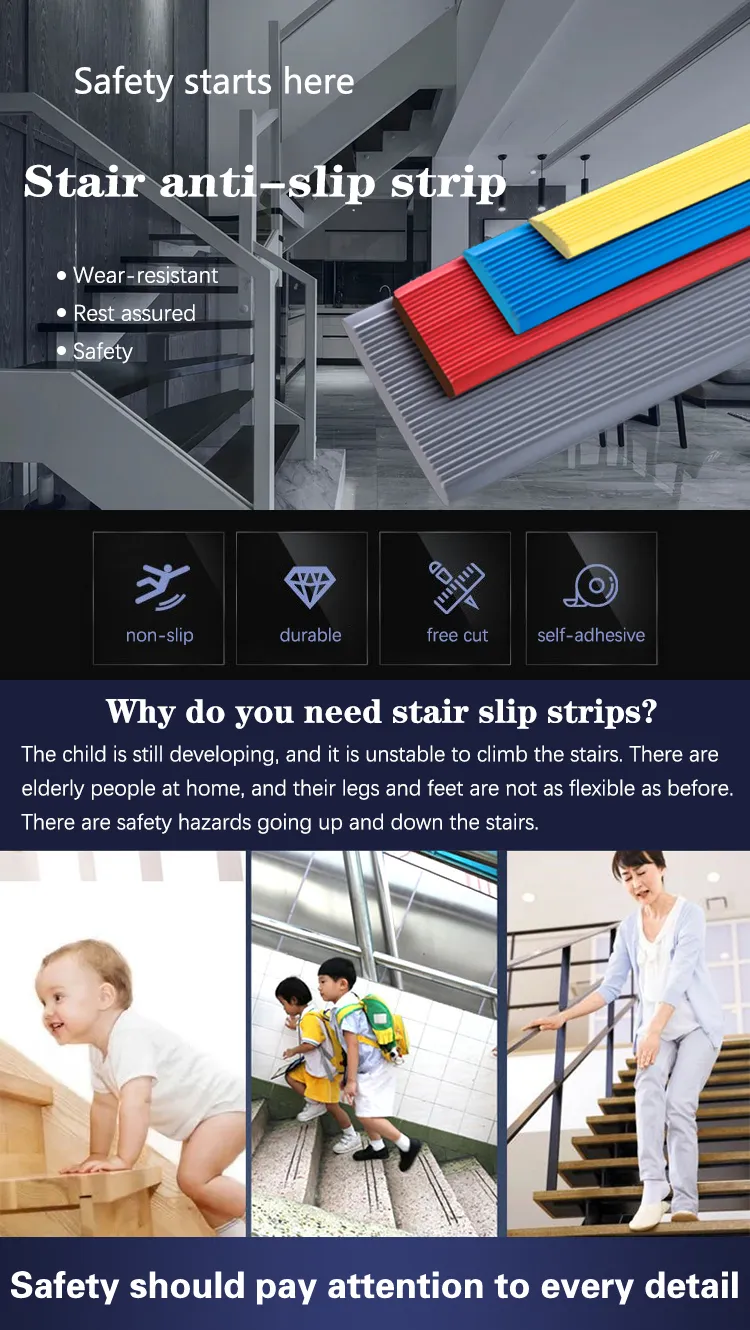

Understanding Shower Anti-Slip Pads

Conclusion

To fix the seal, you'll need a few tools and materials. Typically, these include

4. Anti-Slip Coatings For existing floors, applying anti-slip coatings is an effective way to enhance safety. These coatings can be applied to various surfaces, including concrete and wood, and are often invisible once dried, preserving the floor's original look.

Podsumowując, uszczelki z gumy silikonowej to wszechstronny produkt, który można zastosować w wielu obszarach. Dzięki swoim doskonałym właściwościom, łatwemu montażowi i długotrwałości, stanowią one niezastąpiony element zarówno w budownictwie, jak i przemyśle motoryzacyjnym. Przy ich użyciu można znacząco poprawić komfort i energooszczędność.

The Importance of Weather Stripping

Latest articles

-

Another appealing aspect of laminate stair edge trim is its relatively easy installation process. Many trims are designed for straightforward application, allowing homeowners and DIY enthusiasts to install them without professional help. Moreover, laminate trims are typically easy to clean and maintain, requiring little more than occasional dusting or wiping down with a damp cloth to keep them looking new.

-

У сучасным свеце, дзе лагістыка і захаванне тавараў займаюць ключавую ролю ў бізнэс-працэсах, важна забяспечыць высокі ўзровень бяспекі і эфектыўнасці. Адным з самых папулярных і надзейных рашэнняў, якія дапамагаюць у гэтым, з'яўляецца дак Seal.

-

Заключение

-

Versatile Applications

-

In summary, PVC floor mats offer a versatile and practical solution for enhancing bedroom spaces. Their ability to blend seamlessly with various design aesthetics, coupled with the comfort and durability they provide, makes them a top choice for many homeowners. With easy maintenance and eco-friendly options available, PVC floor mats present an attractive flooring alternative that caters to both style and functionality. As you consider how to optimize your bedroom for comfort and design, investing in a PVC floor mat could be a worthwhile decision that enhances your living space for years to come.

-

Обрізання країв алюмінієвих виробів — це важливий процес, який не лише підвищує безпеку та естетику, але й сприяє довговічності продуктів. Завдяки розвитку технологій та новітніх методів обробки, ці вироби стають все більш популярними в різних галузях. Інвестування в якісну обробку країв може значно підвищити цінність виробу та його конкурентоспроможність на ринку. Алюміній завдяки своїм унікальним властивостям залишається невід’ємною частиною сучасної індустрії, а якісна обробка країв — запорукою успіху.

Links

Assessing Wear in Slurry Pump Parts

By following these steps, you can quickly and effectively select a slurry pump model that meets your specific requirements. Utilizing manufacturer resources such as selection charts and software, understanding your application’s detailed needs, and consulting with experts are key components in making a well-informed and timely decision. Contact us today to learn more about our slurry pump models and how we can assist you in the selection process.

Understanding Slurry Pump Wet End Parts A Comprehensive Overview

In addition to its shape and size, the material used for the volute's construction is also important. Typically, materials such as cast iron, stainless steel, or thermoplastics are employed, chosen based on factors like fluid characteristics, temperature, and pressure. For example, corrosive fluids may necessitate the use of more durable materials to prevent degradation and ensure longevity.

- Reach out to the pump manufacturer’s technical support team for assistance in confirming your selection.

Centrifugal pumps play a pivotal role in various industries, including water supply, chemical processing, and wastewater management. One of the essential components of a centrifugal pump is the volute, which has a significant impact on the pump's performance and efficiency. Understanding the volute's function provides insight into how centrifugal pumps operate and their design considerations.

In various industrial sectors, the efficient handling and transportation of slurry— a mixture of solids and liquids— is critical. Whether in mining, construction, or wastewater treatment, the need for reliable machinery to manage these challenging substances has led to the increased utilization of slurry pumps. Among these, wholesale slurry pumps have emerged as a vital resource, offering a practical solution for businesses looking to optimize their operations.

Understanding the components of the wet end of a slurry pump is vital for anyone involved in industries that rely on such equipment. Proper maintenance and selection of high-quality parts can significantly enhance the efficiency and lifespan of a slurry pump, reducing operational costs and minimizing downtime. By focusing on the critical wet end parts—impeller, casing, wear plates, flanges, and the shaft assembly—operators can ensure their pumps perform reliably in challenging environments.

Evaluating the performance and efficiency of horizontal centrifugal slurry pumps involves a comprehensive approach to testing key metrics such as flow rate, head, and efficiency. These tests are essential for ensuring that the centrifugal slurry pump operates according to expected standards and can handle the demands of slurry transport using centrifugal pumps. Regular monitoring and maintenance of AH Slurry Pump parts further contribute to sustaining the pump’s performance, reducing operational costs, and extending the pump’s service life. By focusing on these critical areas, manufacturers and operators can optimize the performance and reliability of horizontal centrifugal slurry pumps, ensuring their continued success in industrial applications.

Materials: High-chrome iron, ductile iron, and stainless steel are commonly used materials.

By following these steps, you can quickly and effectively select a slurry pump model that meets your specific requirements. Utilizing manufacturer resources such as selection charts and software, understanding your application’s detailed needs, and consulting with experts are key components in making a well-informed and timely decision. Contact us today to learn more about our slurry pump models and how we can assist you in the selection process.

The head, or the height to which a pump can raise the slurry, is another vital performance indicator for horizontal centrifugal slurry pumps. The head is directly related to the pump’s ability to overcome the pressure within the slurry transport system. This metric is typically measured in meters (m) and provides insight into the pump’s power to move slurry through pipelines and other components. The head is crucial for applications involving slurry transport using centrifugal pumps because it determines how efficiently the pump can transport slurry over long distances or through systems with varying elevations. Regular testing of head and pressure ensures that the horizontal centrifugal slurry pump meets the operational demands and maintains system efficiency.

Selecting the appropriate slurry pump model quickly involves understanding your application's specific requirements and matching them with the pump's capabilities.

a. Manufacturer’s Selection Chart:

Function: Shaft sleeves protect the pump shaft from the slurry and the mechanical seals.

- **Particle Size: Identify the maximum particle size in the slurry.

8. Pump Backplate

Types:

The impeller is a rotating component within the pump that transfers energy from the motor to the slurry. It plays a significant role in creating the flow and pressure necessary to move the slurry through the system. Impellers for slurry pumps are typically heavier and more robust than those used in standard pumps to withstand the harsh conditions encountered in abrasive applications. Their design can vary, with options for different shapes and sizes to accommodate specific types of slurries.

- Concentration: Measure the percentage of solids by weight or volume in the slurry.

The Role of the Volute in Centrifugal Pumps

b. Power and Drive Options:

In various industrial sectors, the efficient handling and transportation of slurry— a mixture of solids and liquids— is critical. Whether in mining, construction, or wastewater treatment, the need for reliable machinery to manage these challenging substances has led to the increased utilization of slurry pumps. Among these, wholesale slurry pumps have emerged as a vital resource, offering a practical solution for businesses looking to optimize their operations.

The effectiveness of slurry transport using centrifugal pumps largely depends on the pump’s ability to handle abrasive and viscous materials. Performance testing for slurry transport applications involves assessing how well the horizontal centrifugal slurry pump can move slurry without significant wear or loss of efficiency. This testing includes monitoring the pump’s performance over time, particularly under harsh operating conditions, to ensure that the centrifugal slurry pump can withstand the rigors of slurry transport. Evaluating the pump’s performance in this context helps identify potential issues before they lead to system failures, ensuring that the AH Slurry Pump parts remain in good condition and continue to operate efficiently.

Adapting to High Liquid Level Conditions with SPR Slurry Pumps

The Role of Casting Slurry Pump Parts in Wear Management

b. Operating Conditions:

Function: The pump casing contains the slurry and guides it through the pump.

Vertical stage pumps are a type of multistage pump that is designed to handle high-pressure applications. These pumps are characterized by their ability to generate high pressure through multiple stages, each adding to the total pressure head. Vertical stage pumps are particularly useful in applications where a significant pressure increase is needed, such as in high-rise building water supply systems, boiler feed applications, and pressure boosting systems. The vertical design of these pumps allows for a compact, efficient solution that can deliver the necessary pressure without taking up excessive space. By selecting the appropriate vertical stage pump for your system, you can ensure that your fluid handling needs are met efficiently and effectively.

The impeller is a rotating component within the pump that transfers energy from the motor to the slurry. It plays a significant role in creating the flow and pressure necessary to move the slurry through the system. Impellers for slurry pumps are typically heavier and more robust than those used in standard pumps to withstand the harsh conditions encountered in abrasive applications. Their design can vary, with options for different shapes and sizes to accommodate specific types of slurries.

Maintenance of sewage pump impellers is also vital for ensuring their longevity and functionality. Regular inspection can help identify wear or damage, and timely replacement of worn-out impellers can prevent pump failures and costly repairs. Moreover, keeping the impeller clean from debris buildup ensures optimal performance.

Vertical inline centrifugal pumps offer a streamlined installation process, which is crucial for deep pit applications. The inline design allows these pumps to be integrated directly into existing piping systems, reducing the need for extensive modifications. This not only saves time but also minimizes disruption to ongoing operations. Additionally, the vertical orientation of these pumps makes them easier to align and secure in tight spaces, ensuring stable operation. For deep pit applications, where access can be challenging, the ease of installation provided by vertical inline centrifugal pumps is a significant benefit. Optimizing the installation process further enhances the pump’s performance and longevity in demanding environments.

By following these steps, you can quickly and effectively select a slurry pump model that meets your specific requirements. Utilizing manufacturer resources such as selection charts and software, understanding your application’s detailed needs, and consulting with experts are key components in making a well-informed and timely decision. Contact us today to learn more about our slurry pump models and how we can assist you in the selection process.

Monitoring and Maintaining AH Slurry Pump Parts