Current location:garage door seal bulb type >>Text

garage door seal bulb type

Hebei Qiuzhuo door bottom noise seal3People have read

Introduction...

Latest articles

garage door seal bulb typeSammanfattningsvis är silikon dörrväderstripp en neutral men kraftfull komponent i hemmet som erbjuder utmärkt skydd mot väderpåverkan, effektiv energieffektivitet och långvarig hållbarhet. Oavsett om du bor i en gammal villa eller ett nybyggt hus, kommer installationen av silikon dörrväderstripp att ge dig och din familj mer komfort och trygghet året runt.

...

Read More

garage door seal bulb typeEnfin, au-delà de la sécurité, les tapis antidérapants pour escaliers ajoutent une touche esthétique à votre intérieur. Avec une multitude de motifs et de designs, ils peuvent rehausser l’apparence de vos escaliers et contribuer à l'harmonie de votre espace de vie.

...

Read More

garage door seal bulb typeIn conclusion, while often overlooked, interior door bottom seals are essential for maintaining a comfortable, energy-efficient, and peaceful home environment. They provide numerous benefits, including energy savings, noise reduction, and allergen control. By understanding their importance and ensuring proper installation and maintenance, homeowners can enhance the functionality and comfort of their living spaces. Investing in quality door bottom seals can lead to long-term savings and improved quality of life.

...

Read More

Popular articles

In the quest for comfort and efficiency in our homes, many homeowners tend to overlook the importance of something as seemingly trivial as a draft stopper. These simple yet effective tools play a significant role in regulating indoor temperatures by preventing cold air from sneaking in through the gaps under doors. This article will explore the benefits of using draft stoppers, the different types available, and their contributions to energy conservation.

- One of the main reasons why entry door weather stripping is important is for energy efficiency. When your door is not properly sealed, warm or cool air can escape from your home, causing your HVAC system to work harder to maintain a comfortable temperature. This can result in higher energy bills and unnecessary wear and tear on your heating and cooling systems. By installing weather stripping at the bottom of your door, you can significantly reduce energy loss and save money on your energy bills.

---

What is a Door Bottom Draught Excluder?

A red non-slip bath mat is a perfect combination of safety, comfort, and style. It enhances the vibrancy of your bathroom while providing essential slip resistance and plush comfort underfoot. With their easy maintenance and versatility, red bath mats are not only practical additions to your home but also conscious design choices that celebrate color and comfort. When considering bathroom accessories, think beyond the ordinary—choose a red non-slip bath mat to elevate your bathroom experience.

Easy Installation and Maintenance

Latest articles

-

Firstly, large sink mats provide ample coverage around your sink, capturing spills and minimizing the risk of slips. Their expanded size ensures that a larger surface area is protected from water damage and food residues, which is particularly beneficial in busy households or commercial kitchens. The generous dimensions of these mats help to keep the surrounding counter and floor areas dry, reducing the likelihood of accidents and enhancing safety while working in the kitchen.

-

Installation Process

-

Aesthetic Considerations

-

3. Durability The liner protects the internal mechanisms of the oven door. By absorbing heat and minimizing direct exposure to flames, it extends the lifespan of the oven, reducing the need for costly repairs or replacements.

-

- Adhesive Strength If choosing adhesive pads, ensure that the adhesive is strong enough to hold under pressure but can also be removed without damaging the underlying surface.

-

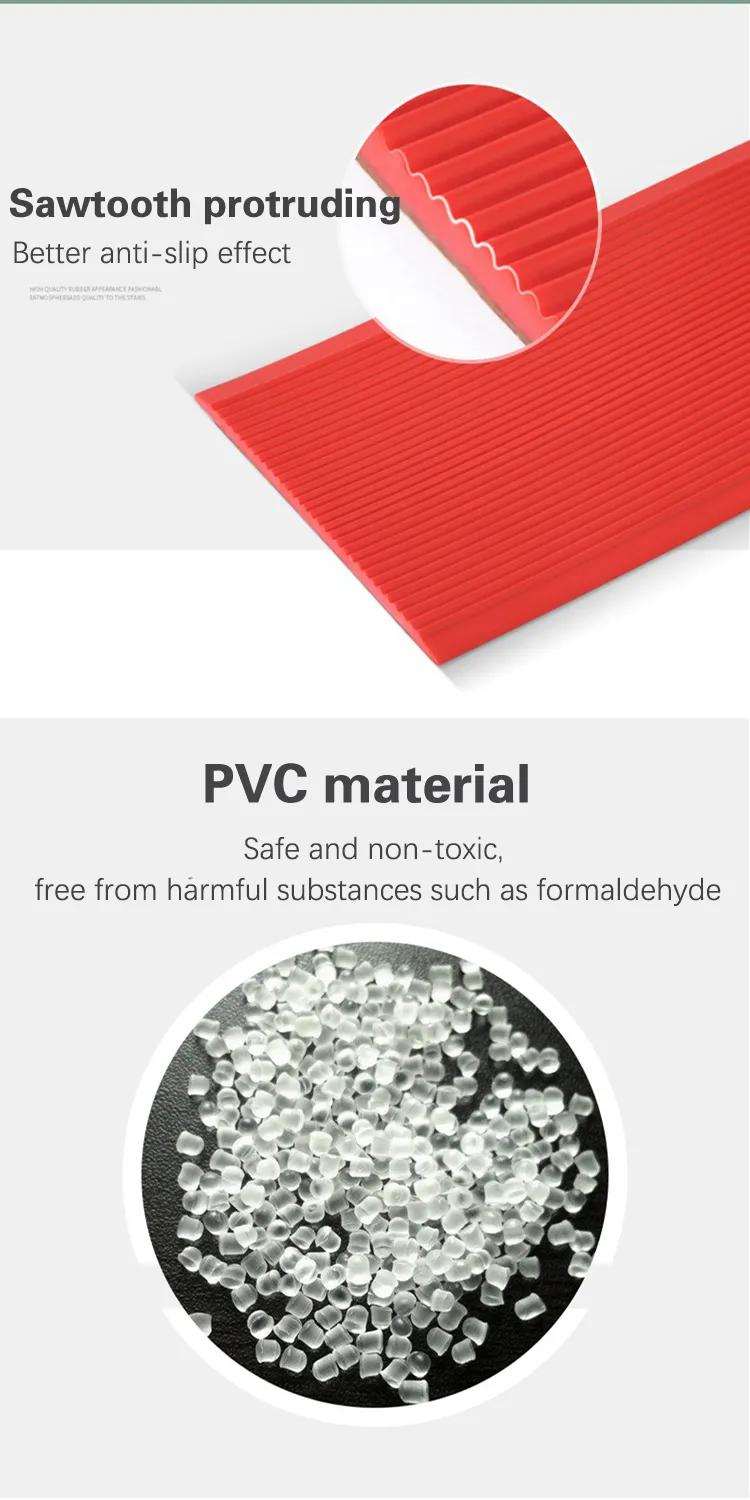

Co wicej, tama PVC jest dostpna w wielu kolorach i wzorach, co pozwala na jej wykorzystanie w celach estetycznych. Mona j stosowa w dekoracji wntrz, gdzie peni rol ozdobn, a jednoczenie praktyczn.

Links

Enhancing Durability with High Pressure Vertical Pumps

Function: The impeller is responsible for moving the slurry through the pump by converting mechanical energy into kinetic energy.

3. Consider Material and Design

Another critical factor in impeller design is the material used for construction. Sewage pump impellers can be made from various materials, including cast iron, stainless steel, or thermoplastics. The choice of material depends on the chemical composition of the waste being pumped. For example, stainless steel impellers offer excellent corrosion resistance, making them suitable for applications involving harsh chemicals.

A pump wet end replacement involves changing out the parts that come into direct contact with the pumped fluid, including the impeller, casing, and liners. Determining the best time to perform this replacement requires careful analysis of the pump’s operating conditions, the wear rate of the components, and the criticality of the pump in your process. By tracking runtime hours, monitoring performance metrics, and assessing wear patterns, you can develop a replacement schedule that minimizes downtime and ensures continuous operation. This strategy not only helps to maintain pump efficiency but also reduces the long-term cost of ownership by preventing major failures.

Vertical inline centrifugal pumps offer a streamlined installation process, which is crucial for deep pit applications. The inline design allows these pumps to be integrated directly into existing piping systems, reducing the need for extensive modifications. This not only saves time but also minimizes disruption to ongoing operations. Additionally, the vertical orientation of these pumps makes them easier to align and secure in tight spaces, ensuring stable operation. For deep pit applications, where access can be challenging, the ease of installation provided by vertical inline centrifugal pumps is a significant benefit. Optimizing the installation process further enhances the pump’s performance and longevity in demanding environments.

Another critical factor in impeller design is the material used for construction. Sewage pump impellers can be made from various materials, including cast iron, stainless steel, or thermoplastics. The choice of material depends on the chemical composition of the waste being pumped. For example, stainless steel impellers offer excellent corrosion resistance, making them suitable for applications involving harsh chemicals.

The performance of horizontal slurry pumps in mining and quarrying is heavily influenced by the quality of their components. AH slurry pump parts are specifically designed to withstand the wear and tear associated with abrasive slurries. Regular maintenance and timely replacement of these parts are essential for ensuring that the pumps continue to operate at peak efficiency. By investing in high-quality AH slurry pump parts, operators can extend the lifespan of their equipment, reduce the frequency of repairs, and minimize downtime. This proactive approach to maintenance not only enhances productivity but also contributes to a safer and more reliable working environment in mining and quarry operations.

Slurry pump parts are particularly susceptible to wear due to the abrasive nature of the materials they handle. Components such as the impeller, casing, and liners are all subject to gradual wear, which can impact pump performance if not managed properly. Regular inspections and wear assessments are key to determining the optimal replacement cycle for these parts. By using advanced monitoring techniques and predictive maintenance tools, you can track the wear rate of slurry pump parts and plan replacements before they cause a significant drop in performance. This proactive approach helps to extend the life of the pump and reduce overall maintenance costs.

The choice between a vertical inline pump and a centrifugal pump depends on various factors, including space constraints, pressure requirements, and maintenance considerations. By carefully evaluating your system's needs and the specific advantages of each pump type, you can select the right pump that meets your operational requirements and ensures long-term reliability.

Establishing a Pump Wet End Replacement Schedule

b. Power and Drive Options:

Efficient Horizontal Slurry Pumps Transport in Mining Operations

Conclusion

- Head: Calculate the total head required (static head plus friction losses).

Tailings management is a critical aspect of mining operations, requiring reliable equipment to handle the byproducts of extraction processes. OEM horizontal slurry pumps are designed to manage the unique challenges associated with tailings, such as the need for pumps that can withstand the abrasive nature of the slurry and the constant demand for high efficiency. These pumps are essential in transporting tailings to designated storage areas, where they can be safely contained and processed. The use of horizontal slurry pumps in tailings management helps minimize environmental impact, as these pumps are capable of handling large volumes of material with minimal leakage or spillage. Additionally, AH slurry pump parts ensure that the pumps maintain their performance over time, even under the harsh conditions often found in tailings processing.

- Choose materials that can withstand the slurry's abrasiveness and corrosiveness. Common materials include high-chrome alloys, stainless steel, and rubber linings.

- Concentration: Measure the percentage of solids by weight or volume in the slurry.

4. Check Pump Performance Curves

a. Material Compatibility:

5. Evaluate Additional Features

In conclusion, sewage pump impellers are integral to wastewater management systems. By understanding their types, materials, and maintenance, operators can make informed decisions that enhance the efficiency and reliability of sewage pumping operations, ultimately contributing to effective waste management solutions.

Function: The impeller is responsible for moving the slurry through the pump by converting mechanical energy into kinetic energy.

Understanding the Role of Propeller Pumps in Various Applications

- Mechanical Seals: Provide a tight seal and reduce leakage.

b. Operating Conditions:

Materials: Materials used for shaft sleeves include hardened stainless steel and ceramic-coated materials.

The Role of the Volute in Centrifugal Pumps

Wear Factors: Continuous contact with the slurry and seals can cause wear on the shaft sleeves.

In conclusion, propeller pumps are an essential component in many industries. Their ability to efficiently handle large volumes of liquid makes them invaluable for water treatment, agriculture, industrial processes, and firefighting. As technology advances, we can expect further innovations in propeller pump design, enhancing their effectiveness and broadening their applications.

Monitoring and Maintaining AH Slurry Pump Parts