Current location:kerf door weatherstripping >>Text

kerf door weatherstripping

Hebei Qiuzhuo door bottom noise seal497People have read

Introduction...

Latest articles

kerf door weatherstripping- Style Choose a mat that complements your interior design. Many options are available, from transparent mats that allow the floor's beauty to shine through, to colorful designs that make a statement.

...

Read More

kerf door weatherstrippingBeyond their practical benefits, non-toxic, non-slip bath mats come in various styles, colors, and designs to suit any bathroom décor. Whether you prefer a minimalist look or a vibrant statement piece, there is a bath mat to match your taste. By enhancing the overall design of your bathroom, these mats contribute to a serene and welcoming atmosphere.

...

Read More

kerf door weatherstrippingIn conclusion, non-slip tub mats are an essential addition to any bathroom used by elderly individuals. They provide a simple yet effective way to reduce the risk of slips and falls, ensuring safety during bathing. By selecting the appropriate mat and maintaining it properly, caregivers and family members can help seniors maintain their independence with confidence. As we prioritize the well-being of our elderly loved ones, implementing these safety measures can significantly improve their quality of life, allowing them to enjoy their daily routines with peace of mind.

...

Read More

Popular articles

Teppetrimmer for trapper En estetisk og praktisk lsning

Pest Control

How Does it Work?

Weather Stripping Door Seals A Comprehensive Guide

1. Non-Slip Texture The mat's surface should provide excellent traction. Look for mats made of rubber or those with textured surfaces that can grip your feet securely even when wet.

- Replacement door seal (ensure it is compatible with your Chef oven model)

Latest articles

-

Types of Silicone Weather Stripping

-

One of the most significant advantages of interlocking PVC mats is their design. These mats come in interlocking tiles, which allow for easy and customizable installation. Users can create unique floor layouts tailored to their space without the need for professional assistance. The interlocking feature ensures that the tiles stay firmly in place, reducing the risk of movement and accidents caused by shifting mats.

-

In addition to its functional benefits, Cleanspace drainage matting is an environmentally friendly choice. The materials used are typically recyclable and designed to last for decades, reducing waste and the need for frequent replacements. This longevity not only benefits homeowners but also promotes sustainable building practices—a growing concern in today’s construction industry.

-

Moreover, aesthetics should not be overlooked. Bathtub mats come in a variety of colors, patterns, and designs, allowing you to choose one that complements your bathroom décor. Whether you prefer a sleek, modern look or a more traditional style, there's an antibacterial mat available that will meet your design preferences while still fulfilling its practical role.

-

The Importance of Anti-Skid Pads Enhancing Safety and Comfort

-

Safety First

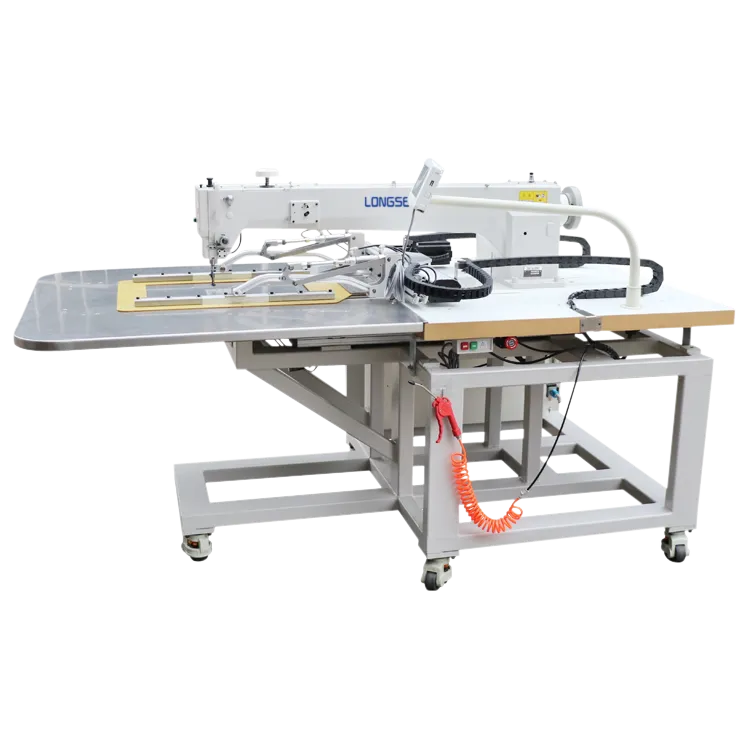

Another key benefit of long arm stitching machines is their versatility. These machines are capable of handling a wide range of fabrics, from delicate silks to heavy denims, with ease. They offer a variety of stitch options, including straight stitch, zigzag stitch, and decorative stitches, allowing you to create intricate designs and patterns on your projects.

long arm stitching machine

The Art and Utility of Long Arm Sewing

The Cost of Zigzag Sewing Machines An Overview

The Art of Sewing Machines for Fur and Leather

Understanding the Long Arm Sail Sewing Machine

single needle juki sewing machine 8100e price. The Juki 8100e is also easy to maintain, with simple cleaning and lubrication procedures that can be done at home.

The versatility of heavy-duty sewing machines extends beyond the realm of fashion and home décor. Industries such as automotive, marine, and theatrical production also rely heavily on these machines for their unique needs. They are used to sew boat covers, car interiors, and stage curtains, all of which demand high levels of durability and wear resistance. As a result, investing in a heavy-duty sewing machine can open up a world of possibilities for entrepreneurs and artisans alike.

Upholstery is a craft that combines artistry with functionality, providing comfort and aesthetics to our living spaces. Among the various techniques used in upholstery, blind stitching stands out as a method that provides a clean and professional finish. This article delves into the essence of blind stitch upholstery, its benefits, and the skill set required to master this technique.

One example is a sailor and his or her understanding that most new boats are going to need a ton of canvas or brightwork done over the years.

Additionally, the trend towards automation in various industries suggests that CNC machine sewing may become a standard practice in textile manufacturing. As costs decrease and technology becomes more accessible, smaller businesses will also benefit from CNC capabilities.

Another popular use for heavy duty sewing machines is in automotive upholstery and repairs. Whether you’re working on restoring a classic car interior or making custom seat covers, a heavy duty sewing machine can handle the tough materials used in automotive upholstery, such as vinyl, leather, and heavy-duty thread.

Conclusion

Benefits of Using Lock Stitch in Jumbo Bags

jumbo bag lock stitch

5. Ease of Adjustment Many industrial sergers come equipped with advanced tension control and stitch length settings, allowing operators to quickly adjust their settings based on fabric type and desired stitch characteristics.

A regular sewing machine requires little to no maintenance. This is perfect for people who only sew as a hobby, as they can set-up the machine and start using it instantly. On the other hand, a heavy-duty machine will require a more regular maintenance schedule. For example, you might need to oil the device, to make sure it keeps working properly. To make sure that you take care of it correctly, you should read the owner’s manual.

Moreover, heavy duty sewing machines often come with a variety of features such as adjustable presser foot pressure, larger throat space for maneuvering bulky fabrics, and multiple stitch types. These design elements make them versatile for various sewing tasks beyond heavy materials.

3. Versatility While primarily designed for upholstery work, these machines can also handle a variety of sewing tasks, from crafting leather goods to sewing quilts or making garments. This versatility makes them a valuable addition to any workshop.

Despite the technological advancements, many craftsmen still value the human touch in leatherwork. The integration of machines does not replace the artisan’s skills; rather, it complements them. Many artisans use machines for the bulk of the stitching, then finish products with hand-stitched details, adding a unique touch that reflects their craftsmanship and storytelling.

4. Cost-Effective Although the initial investment in an industrial overlocker may be higher than a standard sewing machine, the long-term benefits, including reduced labor costs and improved fabric usage, can lead to significant savings.

industrial overlocker for sale

saddle stitch machine. The staples are neatly and securely fastened along the spine of the document, giving it a clean and polished appearance. This makes the document easier to handle and more attractive to readers.

saddle stitch machine. The staples are neatly and securely fastened along the spine of the document, giving it a clean and polished appearance. This makes the document easier to handle and more attractive to readers.The benefits of using an industrial double needle sewing machine go beyond just efficiency. The simultaneous stitching process saves significant time, allowing manufacturers to boost their production rates without compromising quality. Furthermore, the dual threading system reinforces seams, providing additional strength and preventing fabric fraying—an essential characteristic for items subjected to stress and wear.

Final Thoughts

Choosing the Right Walking Foot Leather Sewing Machine

For those looking to achieve a polished, store-bought quality in their creations, a twin needle sewing machine can deliver just that. The use of twin needles allows for consistent stitching and a neatly finished edge on the fabric, which is often a hallmark of high-quality sewing. Whether you’re working on garments, home décor projects, or crafts, the professional finish you achieve with a twin needle will make a significant difference in your final product.

twin needle sewing machine for sale

Applications in Sewing and Crafting

The advantages of using a needle feed sewing machine are numerous. First and foremost, this type of machine minimizes fabric shift, which is particularly beneficial when sewing multiple layers of fabric or intricate designs. By ensuring that the materials remain aligned, the needle feed mechanism produces cleaner seams and higher-quality finished products.

Furthermore, an automatic needle threader can enhance the versatility of sewing machines

. Many modern machines equipped with this technology also come with advanced features such as multiple stitch options, embroidery capabilities, and adjustable speed controls. This combination allows for a more comprehensive sewing experience, where users can explore various projects, from simple repairs to intricate designs, all while benefiting from the ease of automatic threading.Handheld sewing machines are compact, lightweight devices that allow users to perform sewing tasks with one hand. They are typically battery-operated or can be plugged in, making them suitable for quick repairs and alterations. The portability of these machines enables sewists to work on the go, whether at home, while traveling, or at crafting events.

For optimal performance, it's essential to ensure that both threads are properly tensioned. Incorrect tension can lead to various issues, such as thread bunching, skipped stitches, or uneven seams. Therefore, understanding how to adjust the tension on your sewing machine is crucial for achieving perfect lock stitches.

In the world of sewing, the zig zag stitch machine stands out as a remarkable and versatile tool that has revolutionized the way both professionals and hobbyists approach their craft. Since its inception, the zig zag stitch machine has expanded the creative possibilities for fabric manipulation, enabling seamstresses to create intricate designs, reinforce seams, and finish edges with ease.

Moreover, with the rise of eco-friendly sewing practices and sustainable fashions, many makers are turning to upcycling and fabric repurposing projects. The walking foot assists in sewing multiple fabric types together seamlessly, allowing for creativity without compromising on quality.

Preparation is key to successful sewing. It is essential to properly align the fabric and ensure that both needles enter the material at the right points. This can be achieved by using pins or fabric clips to hold layers in place. Additionally, adjusting the machine’s tension and stitch length can help achieve optimal results. A slightly longer stitch length is often recommended for fabrics with more stretch, allowing for flexibility.