Current location:car door seal >>Text

car door seal

Hebei Qiuzhuo door bottom noise seal417People have read

Introduction...

Tags:

Latest articles

car door sealDecks can become slippery due to rain, snow, or condensation, increasing the risk of slips and falls. In fact, falls are among the leading causes of injury, particularly for children and the elderly. Outdoor anti-slip mats serve as a preventative measure, adding an essential layer of safety to your decking. These mats are specifically designed to provide traction and grip underfoot, minimizing the risk of accidents on wet surfaces.

...

Read More

Overall, non-slip sticky mats are an essential tool for preventing slips and falls and maintaining a safe and secure environment in a variety of settings. Whether you are looking to prevent accidents in your home, workplace, or gym, a non-slip mat is a simple and effective solution that can help keep you and those around you safe and secure.

car door seal...

Read More

car door sealTypes of Bathtub Mats

...

Read More

Popular articles

Choosing the Right Drainage Mat

- One of the key advantages of inflatable door seals is their ability to conform to the unique shape and size of the door or opening they are sealing. Traditional seals can be rigid and inflexible, making it difficult to create a perfect seal in irregular or uneven surfaces. Inflatable door seals, on the other hand, can easily inflate and mold themselves to the contours of the door, ensuring a tight and secure seal every time.

Hygiene is another essential aspect of using shower suction mats. Bathrooms are notorious breeding grounds for mold and mildew, particularly in damp areas. Many suction mats are made from materials that resist these growths, but it is crucial to maintain proper hygiene practices. Regularly cleaning your mat is essential; it not only prolongs its life but also prevents unwanted bacteria from accumulating. Most suction mats can be easily removed for cleaning and are often machine washable or easy to wipe down, ensuring that you maintain a clean and healthy bathing environment.

Conclusion

In summary, anti-slip bathroom floor mats serve as an essential component of any bathroom setup. They not only enhance safety by preventing slips and falls but also provide comfort and style. When selecting the right mat, consider factors such as material, design, and ease of maintenance. By prioritizing safety and aesthetics, you can create a bathroom that is both functional and inviting. Ultimately, investing in a good quality anti-slip bathroom mat is a small but significant step toward a safer home environment for everyone.

Benefits of Rubber Door Bottom Sweeps

Latest articles

-

In an age where energy efficiency and environmental sustainability are priority concerns, the significance of gasket weather stripping cannot be overstated. This simple yet effective solution plays a crucial role in maintaining indoor comfort, reducing energy costs, and extending the lifespan of heating and cooling systems.

-

To ensure that your non-slip mat remains effective, regular maintenance is essential. Most mats can be cleaned easily, but it’s important to follow the manufacturer's instructions for washing and drying. Regularly inspect your mat for signs of wear and tear, as this can impact its slip-resistant properties. Replacing your mat every couple of years is a good practice to ensure ongoing safety.

-

Key Features to Consider

-

In summary, anti-slip mats play a vital role in enhancing safety across various environments. Their ability to prevent accidents, coupled with their versatility and ease of maintenance, makes them an essential addition to both homes and businesses. As slip and fall incidents continue to pose significant risks, the adoption of anti-slip mats is a simple yet effective strategy to foster safer spaces. Embracing such safety solutions not only protects individuals but also promotes a culture of care and responsibility within our communities.

-

Installing a rain guard is a relatively simple process that many homeowners can manage on their own. Here are some basic steps to consider

-

Benefits of Using Drainage Mats

Links

Conclusion

- The durability of black and yellow floor marking tape is another key factor in its widespread use. Made from strong materials like vinyl or polyester, these tapes are resistant to wear, tear, and chemical exposure, ensuring long-lasting visibility. Their adhesive backing ensures they stay in place even in high-traffic or harsh conditions.

- Circuit Protection:They come with protective features such as fuses and circuit breakers, which safeguard your electronics from excess current or short-circuiting.

- 3. Temperature resistance Good quality door seal tape should be able to maintain its seal in a wide range of temperatures, ensuring consistent performance throughout the year.

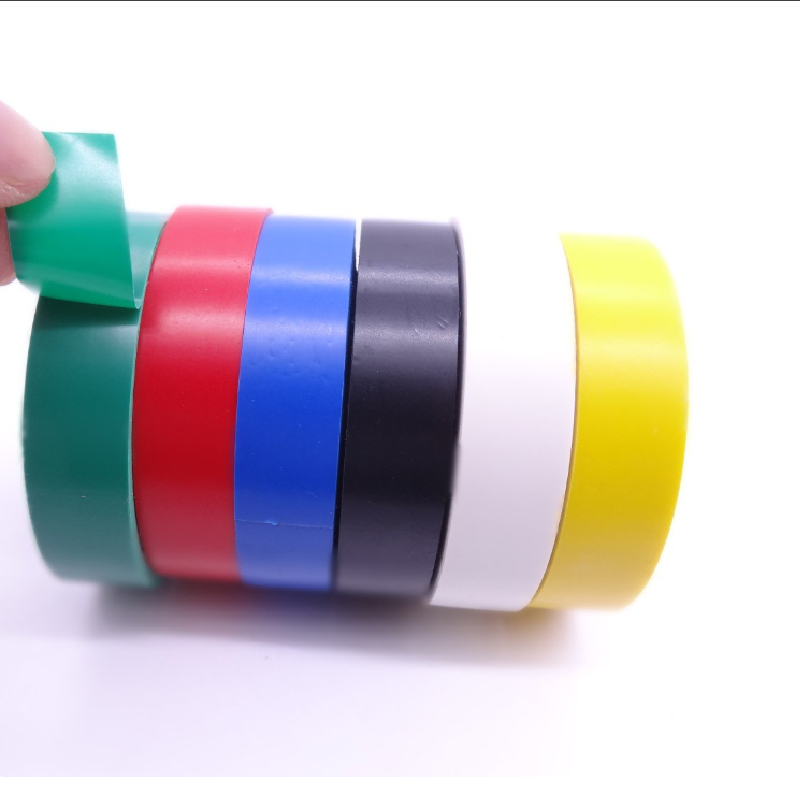

- One of the main uses of insulation tape is for electrical work. When working on electrical projects, it is crucial to have a reliable and high-quality insulation tape to properly insulate wires and connections. This helps prevent electrical shocks, short circuits, and other hazardous situations that can arise from exposed wires. The 50mm insulation tape is a popular choice among professionals and hobbyists alike because of its durability and effectiveness in insulating electrical components.

Homeowners and industry professionals often view butyl tape as an all in one solution because of its multifunctionality. Follow on for a closer look at some of the primary uses of butyl tape.

You need to know how much voltage you have supplying the water system so you can determine which well control box to get.

fire resistant adhesive.

In addition to plumbing, heat tape is vital in agricultural applications. Farmers often use it to maintain soil temperature, ensuring seedlings and crops grow optimally in cooler climates. Furthermore, heat tape can be employed in greenhouses to prevent plants from freezing during cold spells, thus extending the growing season.