Current location:under door sweep interior >>Text

under door sweep interior

Hebei Qiuzhuo door bottom noise seal3956People have read

Introduction...

Latest articles

under door sweep interiorEnergy Efficiency

...

Read More

under door sweep interiorBenefits of Non-Slip Chair Mats

...

Read More

under door sweep interiorIn the world of manufacturing and woodworking, edge banding tape plays a crucial role in enhancing the appearance and durability of products. This thin strip of material, usually made from PVC, ABS, melamine, or wood veneer, is applied to the exposed edges of boards and panels. It not only improves the aesthetics of furniture and cabinetry but also protects edges from moisture, wear, and other environmental factors. As the demand for high-quality furniture and interior solutions continues to rise, edge banding tape manufacturers are stepping up to meet the needs of the industry.

...

Read More

Popular articles

Once installed, maintenance is relatively minimal. Regular inspections to check for wear and tears are essential, as rubber can degrade over time. If you notice cracks, gaps, or brittleness, it’s time to replace the seals to continue enjoying their benefits.

Benefits of Bulb Type Bottom Weather Seals

Furthermore, foam protection also provides thermal insulation, which is essential for maintaining temperature-sensitive products such as pharmaceuticals and food items during transit. By regulating temperature fluctuations, foam minimizes spoilage or degradation, ensuring that products reach consumers in optimal condition.

The increasing prevalence of gecko non-slip matting in various sectors highlights its vital role in enhancing safety and functionality. By mimicking the natural properties of gecko feet, this innovative solution addresses a common problem faced in many settings—slip and fall accidents. With its multitude of benefits, including enhanced safety, versatility, durability, and appealing aesthetics, gecko non-slip matting is a smart choice for anyone looking to improve their environment's safety. As awareness of workplace and home safety continues to grow, products like gecko non-slip matting will likely play an even more prominent role in our daily lives, ensuring that safety is not compromised in the pursuit of functionality and style.

Additionally, Enka drain mats are significant in road construction and subgrade stabilization. The mats assist in managing water within the soil, reducing the potential for shifting and settling, which can lead to pavement cracks and other structural issues. Their robustness allows these mats to withstand heavy loads, making them ideal for use in high-traffic areas.

When selecting an anti-fatigue mat, consider factors such as thickness, material, and size. A thicker mat generally offers more cushioning, but it should also be firm enough to provide support. Look for mats made from high-quality materials that are durable and easy to clean. Additionally, the size should fit the work area, providing enough surface coverage to accommodate movement.

Latest articles

-

Providing Comfort

-

5. آببندهای خودچسب

-

Incorporating drop seals into fire doors comes with numerous benefits

-

Material Matters

-

-

Applying wood edge banding tape is a straightforward process that can be done with basic tools and materials. First, measure the length of the edge that needs to be covered and cut the tape to size. Then, use a hot iron or edge banding machine to apply the tape to the edge of the wood, making sure to trim any excess material for a clean and flush finish.

Links

HPMC-Kapseln für Nahrungsergänzungsmittel

- One of the key advantages of HPMC is its biocompatibility and safety for human use. It is non-toxic, hypoallergenic, and environmentally friendly, making it a preferred choice for many industries. Its inert nature ensures that it does not react with other ingredients or cause adverse effects on the end-users.

- HPMC A Comprehensive Address Solution for Modern Businesses

- In conclusion, cello size is an important consideration for cellists of all levels. By choosing a cello size that is appropriate for their body size and playing style, cellists can ensure a comfortable and enjoyable playing experience. Whether playing a full-size cello or a smaller size instrument, the most important thing is to make beautiful music and enjoy the journey of learning and mastering the cello.

- In the food industry, HPMC is used as a food additive to improve the texture and stability of a variety of food products. For example, HPMC can be used as a thickener in sauces and dressings, as a stabilizer in ice cream and other frozen desserts, and as a binder in baked goods. HPMC is also commonly used in the construction industry as a cement admixture, where it can help to improve the workability and water retention properties of cement mixtures.

- In conclusion, hydroxyethyl cellulose powder is a versatile and widely used ingredient in the personal care and pharmaceutical industries. Its unique properties make it an essential component in a wide range of products, from cosmetics to pharmaceuticals. Its biodegradability, non-toxicity, and versatility make it an attractive option for manufacturers looking to create high-quality, safe, and effective products.

- Perhaps most importantly, RDP Polymer is designed with the end-user in mind, offering a range of customization options that allow users to tailor their remote desktop experience to their specific needs. From customizing the interface layout to setting up keyboard shortcuts and mouse gestures, RDP Polymer gives users the flexibility to work efficiently and comfortably in a remote environment.

- In the oil and gas industry, HEC is used as a fluid loss controller in drilling fluids. These fluids are used to lubricate and cool the drill bit while maintaining the integrity of the wellbore. HEC helps to prevent the loss of fluid into the porous rock formations, ensuring efficient drilling operations.

- In the pharmaceutical industry, redispersible emulsion powder is used to encapsulate drugs and create controlled-release formulations. This allows for the gradual release of medication into the body, ensuring maximum efficacy and patient compliance.

- China's HPMC Factory A Pioneer in the Pharmaceutical Industry

- In conclusion, MHEC-METHHYL Hydroxyethyl Cellulose is a highly versatile polymer with a broad range of applications in various industries. Its unique properties, such as excellent thickening ability, thermal stability, and film-forming properties, make it an indispensable material in many modern technologies. As research and development in this field continue to advance, we can expect to see even more innovative uses for this remarkable polymer.

- Understanding the Viscosity and Concentration of Hydroxyethyl Cellulose

In ophthalmology it is used due to its good wetting properties, excellent tissue and endothelium protection, efficient volume replacement and quick removal. Specifically, it can be used to wet the cornea during cataract, corneal or retinal procedures.

With RDP, users can access all their applications, files, and resources as if they were sitting right in front of the remote computer With RDP, users can access all their applications, files, and resources as if they were sitting right in front of the remote computer

With RDP, users can access all their applications, files, and resources as if they were sitting right in front of the remote computer With RDP, users can access all their applications, files, and resources as if they were sitting right in front of the remote computer vae rdp. This technology has revolutionized the way we work, fostering flexibility and productivity by enabling remote work, collaborative projects, and efficient IT support.

vae rdp. This technology has revolutionized the way we work, fostering flexibility and productivity by enabling remote work, collaborative projects, and efficient IT support.

hpmc price.

3)Hydroxypropyl Methylcellulose exhibits stability in acidic and alkaline conditions, with its aqueous solution remaining stable within a pH range of 2 to 12. It is minimally affected by sodium hydroxide and lime water, but alkaline conditions can accelerate its dissolution and slightly increase viscosity. Hydroxypropyl Methylcellulose demonstrates stability in the presence of common salts, although at higher salt concentrations, there is a tendency for increased viscosity in its solution.

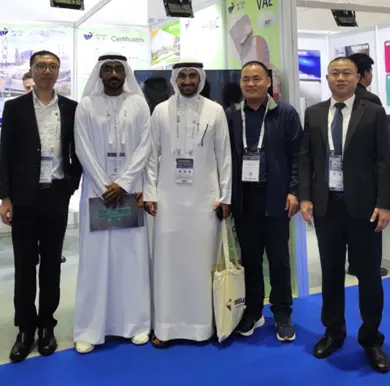

We attended the BIG FIVE exhibition hold in DUBAI during Dec. 5-8 th of 2022. Along with our chairman of the company, we met a lot of new and old customers. Most of them are from construction and detergent product production field. We investigated the market and compared the quality from the market, and found our goal and made our plan for the next year. To serve better to our buyers.

When mixed with water, they quickly dissolve, forming a smooth and uniform coating When mixed with water, they quickly dissolve, forming a smooth and uniform coating

When mixed with water, they quickly dissolve, forming a smooth and uniform coating When mixed with water, they quickly dissolve, forming a smooth and uniform coating