Current location:pvc diamond plate >>Text

pvc diamond plate

Hebei Qiuzhuo door bottom noise seal9People have read

Introduction...

Latest articles

pvc diamond plateSarı kaymaz banyo paspasları aynı zamanda çevre dostu malzemelerden üretilmektedir. Ekolojik problemler göz önüne alındığında, doğal ve geri dönüştürülebilir malzemeler kullanmak büyük bir önem taşır. Bu tür paspaslar, hem doğaya zarar vermemek hem de evimizde sağlıklı bir yaşam ortamı sağlamak adına tercih edilmelidir.

...

Read More

pvc diamond plateUnderstanding Anti-Skid Pads Enhancing Safety and Stability

...

Read More

pvc diamond plateToday's non-slip solutions are not just functional; they are also stylish. Bath mats and treads come in various colors, patterns, and materials, allowing homeowners to enhance their bathroom's design. Textured tiles that promote safety can also be found in elegant designs, integrating seamlessly into modern or traditional decors.

...

Read More

Popular articles

In conclusion, the garage door rubber bottom is a crucial element that contributes significantly to the functionality and protection of your garage and home. Its roles in safeguarding against the elements, enhancing insulation, reducing noise, and preventing pest invasions cannot be overstated. As such, homeowners should prioritize the maintenance and replacement of this vital component, ensuring their garage remains a secure and efficient part of their living space.

The Importance of Choosing the Right Bath Mat for Your Shower Stall

Jakmile jsou dřevěné pásky na hrany správně aplikovány, mohou být následně upraveny a broušeny, aby se dosáhlo dokonalého vzhledu. Tím je zajištěno, že spojení mezi páskem a dřevěným povrchem vypadá přirozeně a harmonicky. Tento proces je klíčový pro dosažení vysoké kvality a trvanlivosti výrobku.

Aesthetic Appeal

Naast bescherming en hygiëne biedt deze mat ook een zekere mate van geluidsisolatie. Het dempt geluidsoverlast van rijdende lading, wat kan helpen om uw rijervaring te verbeteren, vooral als u lange ritten maakt. Dit kan ook de levensduur van uw vrachtwagen verlengen, omdat het de impact op de laadruimte vermindert.

3. Ease of Installation Dimple drainage mats are relatively easy to install compared to traditional drainage systems. They can be rolled out and cut to fit various spaces, making them a convenient choice for both professionals and DIY enthusiasts. Their lightweight nature also simplifies transportation and handling during installation.

Latest articles

-

A weighted under door draft stopper is designed to fit snugly against the bottom of a door, preventing drafts from entering the room. Its weighted nature allows it to remain in place without sliding around, unlike traditional draft stoppers that may easily be displaced. Crafted from various materials, these devices typically feature a filling that adds weight, ensuring they are effective while remaining aesthetically pleasing.

-

Public spaces, such as hospitals, schools, and community centers, see a diverse range of individuals moving about daily. The installation of safety corner covers in these areas can help prevent accidents and maintain a secure atmosphere. This proactive approach contributes to public safety and can reduce the likelihood of lawsuits related to negligence.

-

Beyond safety and functionality, corner shower mats come in a variety of colors, patterns, and materials, allowing you to express your style. Whether you prefer a minimalist look, vibrant colors, or intricate designs, there is likely a corner shower mat that will complement your bathroom décor. Materials such as bamboo, memory foam, and cotton blends not only provide comfort underfoot but also add a touch of elegance to your space. Investing in a stylish corner shower mat is a simple yet effective way to elevate the visual appeal of your bathroom.

-

There are a variety of options available when it comes to stair tile edge trim. From metal to plastic to wood, you can choose the material that best suits your style and needs. Metal trim adds a modern and sleek look, while wood trim provides a more traditional and rustic feel. Plastic trim is a budget-friendly option that still offers durability and protection.

-

Auto weather stripping is an essential component of any vehicle, contributing significantly to overall comfort, efficiency, and longevity. This often-overlooked feature plays a vital role in protecting the interior of a car from external elements such as rain, wind, dust, and noise. Understanding its function, types, and maintenance can help car owners ensure their vehicles remain in top condition.

-

Installation and Maintenance

Links

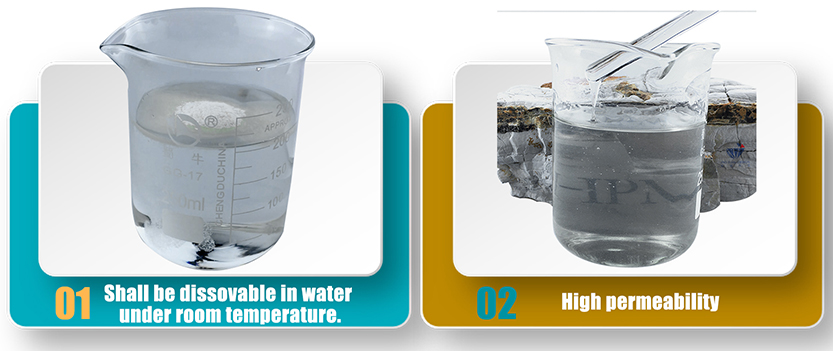

- One of the key benefits of redispersible polymer powder is its ability to improve the workability and bonding strength of construction materials. By adding these powders to mortar or adhesive mixes, manufacturers can enhance the overall performance of the products, making them more resistant to cracks, water penetration, and other environmental factors.

HPMC is generally recognized as safe (GRAS) by the U.S. Food and Drug Administration (FDA) when used in food applications. Its non-ionic nature and lack of adverse environmental impacts make it a preferred choice for many manufacturers. As a biodegradable polymer, HPMC poses minimal risk to the environment, making it a favorable alternative to synthetic polymers that are not easily broken down.

Conclusion

In conclusion, hydroxyalkyl cellulose is a versatile and valuable ingredient with a broad range of applications across multiple industries. Its unique properties, including water solubility, gelation, and thickening capabilities, make it indispensable in pharmaceuticals, cosmetics, food, agriculture, and construction. As innovation continues to drive demand for sustainable and effective alternatives, hydroxyalkyl cellulose is poised to play an increasingly significant role in advancing formulations that enhance product performance while adhering to eco-friendly principles.

- Highly Tolerant of Acids

Applications in the Construction Industry

In consideration of the proposed revision of the limit for propylene chlorohydrins, the Committee took into account the extensive available toxicological database, most notably studies conducted by the United States National Toxicology Program. These data, together with the Committee’s previous estimate of dietary intake of HPMC, indicated that levels of propylene chlorohydrins up to 1 mg/kg in HPMC were not of toxicological concern.

- In the cosmetics industry, HPMC is used in a wide range of products including creams, lotions, and hair styling products. HPMC functions as a thickener, emulsifier, and film-former in these formulations. Our HPMC is designed to enhance the sensory properties and stability of cosmetic products, ensuring they meet the high standards of consumers.

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether primarily used in construction, pharmaceuticals, food processing, and other industrial applications. Its unique properties, including water solubility, film-forming ability, and thickening capacity, make it a critical ingredient in various formulations. As industries evolve and global supply chains fluctuate, the pricing of HPMC is influenced by a multitude of factors that stakeholders must understand to navigate this complex market.

RDPs are typically made from emulsion polymers that have been dried into a powder form. When mixed with water, these powders can easily redispersed into a uniform aqueous dispersion. This property is particularly advantageous in construction, as it allows for easier handling and transportation of materials. Moreover, RDPs can be added to a wide range of formulations, such as adhesives, sealants, mortars, and renders, thereby enhancing their overall performance.

Materials Required

In conclusion, hydroxypropyl methylcellulose is a remarkable compound with a broad spectrum of applications across various sectors. Its versatility, coupled with its effectiveness as an excipient, thickener, and stabilizer, underscores its importance in modern formulations. As industries continue to innovate and expand, HPMC will likely play a pivotal role in meeting the demands for high-performance products that align with consumer expectations and sustainability goals. Through responsible use and continuous research, HPMC can remain a vital ingredient in the development of advanced materials and formulations.

Over the years, gelatin capsules have been the preferred choice of hundreds of pharmaceutical and nutraceutical industries and are forecasted to remain relatively popular. However, as more consumers are demanding “natural” products, vegetable-based capsules have begun to penetrate leading markets in Western Europe, Canada and the United States.

One of the most significant applications of HPMC is in the pharmaceutical industry. It is commonly employed as a controlled-release agent in drug formulations, ensuring that medications are released in a sustained manner. HPMC is also used as a binder in tablets and as a thickener in various liquid formulations, providing the necessary viscosity to ensure stability and efficacy.

In the pharmaceutical sector, HPMC is a crucial excipient used in drug formulations. HPMC Limited provides high-quality products that enhance the efficacy of medications, ensuring they are safe and effective for patients. The company adheres to stringent quality control standards, with a focus on compliance with regulatory requirements. This commitment to quality has earned HPMC Limited a reputation as a trusted partner in the pharmaceutical industry.

is hpmc safe. HPMC is considered safe for consumption by the general population, including children and pregnant women.

In summary, Hydroxypropyl Methylcellulose is a widely utilized compound that has been deemed safe by various regulatory authorities. Its applications in food, pharmaceuticals, and cosmetics underline its versatility and importance in multiple industries. While HPMC generally poses minimal risk to consumers, it is essential for individuals to remain informed about potential sensitivities and consult healthcare professionals when necessary.

- Versatility HEC’s multifunctional properties allow it to be used across diverse industries. Whether in cosmetics, pharmaceuticals, or construction, its adaptability makes it invaluable.

Challenges Faced by HPMC Manufacturers

Hydroxypropyl methyl cellulose (HPMC) is a semi-synthetic polymer derived from cellulose, a natural polymer found in plant cell walls. It is widely used in various applications, from food products and pharmaceuticals to cosmetics and construction. As a food additive, it acts as a thickening agent, emulsifier, and stabilizer. In the pharmaceutical field, it is often used as a binder and coating agent in tablets and capsules. While HPMC is generally regarded as safe, understanding its potential side effects is crucial for consumers and industry professionals alike.

4. Cooling the Solution Once the HPMC is fully dissolved, remove the container from heat and allow the solution to cool to room temperature. As it cools, the viscosity will increase, and the solution will become thicker.

5. Pharmaceutical Suppliers

1. Pharmaceutical Industry One of the primary uses of HPMC sheets is in pharmaceuticals. They are often employed as excipients in drug formulations, serving as thickeners, binders, and film-forming agents. They can control drug release rates, improving the efficacy and bioavailability of medications.

In the pharmaceutical industry, HMPC serves multiple roles, especially as a binder, film-forming agent, and controlled release agent in tablet formulations. Its film-forming properties are particularly beneficial for coating tablets, ensuring a uniform appearance while also providing protection against environmental factors such as moisture and light. Moreover, the use of HMPC allows for the controlled release of active pharmaceutical ingredients (APIs), facilitating sustained therapeutic effects over extended periods. This controlled release mechanism improves patient compliance and enhances the efficacy of treatment regimens.

hydroxy methyl propyl cellulose

1. Sourcing and Quality Assurance HPMC importers must ensure they source high-quality products that meet specific industry standards. This involves evaluating suppliers, conducting audits, and ensuring that the materials undergo rigorous testing to confirm their purity and effectiveness. Only through diligent sourcing can importers guarantee that the HPMC they supply is suitable for use in sensitive applications, such as pharmaceuticals.

hpmc importer

Hypromellose is a semi-synthetic polymer, a derivative of cellulose that undergoes chemical modification. By substituting specific hydroxyl groups in cellulose with hydroxypropyl and methyl groups, HPMC gains a range of useful characteristics. HPMC is soluble in both hot and cold water, forming a clear, viscous solution, which makes it advantageous for numerous applications. The degree of substitution of the methyl and hydroxypropyl groups can be tailored, leading to various grades of HPMC with different viscosity and solubility profiles.

3. Construction Grade HPMC This grade of HPMC is utilized in construction materials such as tile adhesives, joint compounds, and cement. Its water retention capabilities and binding properties improve the workability, adhesion, and durability of construction products.

What is HPMC?

HPMC is derived from cellulose, a natural polymer, and is modified to enhance its solubility and functionality. It is a white, odorless powder that readily dissolves in cold or warm water, creating a gel-like solution. Due to its unique rheological properties, HPMC is commonly used as a thickening agent, emulsifier, and stabilizer in various formulations. It has become a preferred choice in the pharmaceutical industry for formulating controlled-release drug delivery systems, as it can modulate the release rate of active pharmaceutical ingredients (APIs).

Conclusion

One of the primary applications of RDP powder is in the construction sector, particularly in dry-mixed mortars. When mixed with water, RDP powder provides enhanced adhesion, elasticity, and flexibility to the mortar. This leads to improved durability and performance of the final product. For instance, RDP is widely used in tile adhesives to enhance their bonding strength to substrates such as concrete, ceramic, and wood. The polymer’s ability to maintain consistent performance under varying environmental conditions makes it a staple in both indoor and outdoor applications.

dispersible polymer powder. Additionally, dispersible polymer powders can also be used to create controlled-release formulations that provide a sustained release of the active ingredient over time.

Several materials have been tested as a substitute for gelatin capsules. Hydroxypropylmethylcellulose (HPMC) has become a successful alternative material for two-piece capsules and is used for supplements all over the world.

Vegetarian HPMC capsules are made from 100% plant-sourced ingredients i.e. hypromellose that digest easily. They are perfectly healthy and do not contain any animal-by products or animal-borne contaminants.

They also do not trigger any allergic reaction or cause side effects, even on prolonged use. Typically, veggie capsules are vegan, Halal, and Kosher certified. That satisfies consumers with religious considerations.

Manufacturers produce these capsules in cGMP-approved facilities and follow a rigorous quality assurance process in their operations. Capsuline manufacturing facilities are cGMP certified and hold IS0-100 quality control certification to guarantee the traceability of materials. Also, all raw materials used are FDA 'Generally Regarded As Safe' (GRAS)-standard.

You can also choose the desired variety of these capsules that possess your preferred type of colorant, opacifier, or coating material.

Nevertheless, veggie capsules promote your health by enhancing the way active drugs are absorbed and utilized in your body.

Hydroxypropyl methylcellulose (HPMC) is a widely used cellulose ether, renowned for its versatility and effectiveness in numerous applications across various industries. As a non-ionic compound derived from natural cellulose, HPMC is valued for its ability to modify the properties of substances, making it a key ingredient in a range of products. This article explores the diverse uses and benefits of HPMC, highlighting its significance in pharmaceuticals, food production, construction materials, and personal care products.

Raw Materials

The structural characteristics of hydroxyethyl cellulose play a key role in defining its physicochemical properties and diverse applications. As a natural polymer modified to enhance its functionalities, HEC has established itself as an essential ingredient across multiple sectors. Its versatility, combined with an increasing focus on sustainable and safe materials, will likely continue to drive innovation and expand its usage in the future. As research advances, new formulations and applications of this valuable compound will undoubtedly emerge, reinforcing the relevance of hydroxyethyl cellulose in modern industries.

Hydroxypropyl Methylcellulose (HPMC) is a semi-synthetic polymer derived from cellulose, a natural polymer found in plant cell walls. Due to its versatile properties, HPMC is widely used in food, pharmaceuticals, and construction industries. One interesting aspect of HPMC is its solubility in various solvents, particularly ethanol. Understanding the solubility characteristics of HPMC in ethanol is critical for optimizing its applications and formulations.