Current location:non slip wheelchair mat >>Text

non slip wheelchair mat

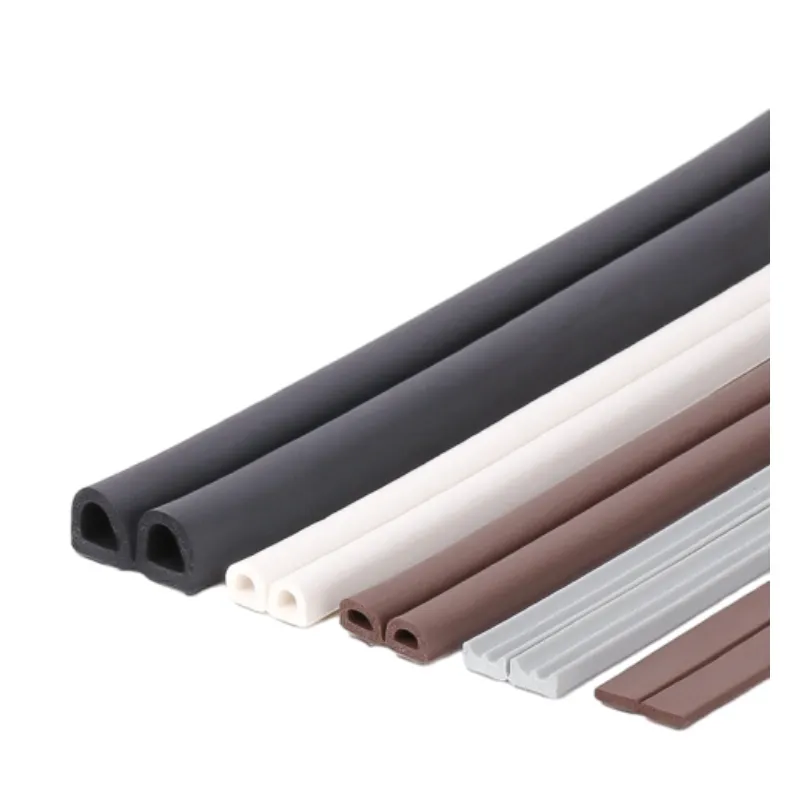

Hebei Qiuzhuo door bottom noise seal4563People have read

Introduction...

Tags:

Previous: 3. Noise Reduction Another significant advantage is the ability of soft floor coverings to absorb sound. Unlike hard surfaces that tend to amplify noise, soft coverings can dampen sounds from footsteps, voices, and other activities, contributing to a quieter and more peaceful environment.

soft floor covering

Latest articles

non slip wheelchair matConclusion

...

Read More

non slip wheelchair matOne of the most effective ways to protect furniture corners is by using corner guards. These are soft, cushioned protectors that can be easily applied to the edges of furniture. Available in various styles and materials, corner guards not only absorb impact but also offer a safe option for homes with young children or pets. They come in transparent designs that blend seamlessly with most furniture or can be found in decorative shapes and colors to enhance your decor.

...

Read More

non slip wheelchair matBeyond functionality, metal step edge trim also plays a pivotal role in interior and exterior design

. With various finishes and styles available, it can complement virtually any design aesthetic. From sleek modern designs to more intricate traditional styles, metal trims can be tailored to fit the architectural vision of a space....

Read More

Popular articles

Metal step edge trim is an indispensable element in staircase design, combining safety, durability, and aesthetic value. Whether you are renovating a home or designing a commercial space, considering the integration of metal step edge trims can elevate both the functionality and visual appeal of your staircase, making them a wise investment for any project.

In residential environments, round anti-slip mats can be placed in high-risk areas such as showers or bathtubs to prevent falls. In commercial kitchens, they can ensure that staff remain safe while navigating wet surfaces. In outdoor settings, round anti-slip mats can be used around pools or patios, providing a secure footing for guests and family members.

1. Plastic Corner Protectors Lightweight and often economical, these are common in homes and educational settings. They come in various colors and shapes, making them a versatile option for aesthetic integration.

4. Versatility These strips are versatile and can be installed on various types of stairs, including wood, metal, and concrete surfaces. This adaptability makes them suitable for homes, schools, offices, and public buildings. Whether it’s an outdoor staircase exposed to weather elements or indoor stairs with heavy foot traffic, slip-resistant stair strips are an effective solution.

Maintenance is also relatively straightforward; most metal trims can be cleaned with mild detergents and do not require specialized treatments. This ease of maintenance ensures that the trims continue to look polished and integrated into the overall design, providing both function and form with minimal effort.

Aesthetics and Style

Latest articles

-

Die Randverkleidung einer Treppe, oft auch als Treppenverkleidung oder -trim bezeichnet, spielt eine wesentliche Rolle in der Treppengestaltung. Sie verdeckt nicht nur die Kanten des Treppenstufenmaterials, sondern sorgt auch für einen nahtlosen Übergang zwischen Stufen und Wänden. Eine wohldefinierte Verkleidung kann den visuellen Eindruck einer Treppe erheblich verbessern, indem sie einen eleganten und abgeschlossenen Look bietet.

-

5. Professional Inspection For comprehensive evaluations and repairs, consider having your vehicle checked by a professional. They can assess not just the window seals but also other components affected by wear and tear due to environmental factors.

-

Conclusion

-

Installation and Maintenance

-

The Importance of Non-Slip Mats for Floors

-

The Versatility of Cupboard Edge Tape

Links

- Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

- Using rubber as a wear lining material means

- A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

- Slurry Pump

- The most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

- The slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

- In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

- Choosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

- Many types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

- To reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- Dredge Pump

- Choosing the right slurry pump

- The company uses advanced computer assistant engineering software to design products and technology, which makes our

- Repairable - target=_blank title=Rubber Lined Slurry Pumps>Rubber lined slurry pumps can be repaired by simply replacing the bushing.

- Magnetite mixing

- - Keeping clean catch basins clean from solids

- >Slurry Pump vs Mud Pump

- sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

- Dry Installation

- Corrosiveness of the slurry

- - Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

- Light-duty Slurry Pump

- >Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

- Rubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

- Dredge Pump

- Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High

- Low slurry flow rates

- Consider the following.

- Underwater installation

- I hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

- Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

- Another important target=_blank title=Part of the Slurry Pump>part of the slurry pump is its casing, which bears all the pressure. The slurry pump casing should have a large clearance between the impeller and the diversion angle to reduce wear and prevent large solid particles from getting stuck. Due to the extra space, there is more recirculation in the slurry pump casing under various operating conditions. Again, this accelerates wear compared to typical pumps.

- Pumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

- Dredge pumps are designed to transfer large quantities of fluids and solids.

- method and level of design reach international advanced level. The company has the first-class pump performance

- Determine the operating parameters of the pump.

- Mud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

- Slurry Pump

- The concept of the , slurry pump, and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

- If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

- It is important that the pump you choose has components that will not wear out from abrasive slurries.

- Mixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

- Determine the nature of the material to be pumped

- Slurry Pump

- What is the best seal arrangement for the application?

- The construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

- Slurry Pump Speed

- - Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

- Pumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.