Current location:wood step edge trim >>Text

wood step edge trim

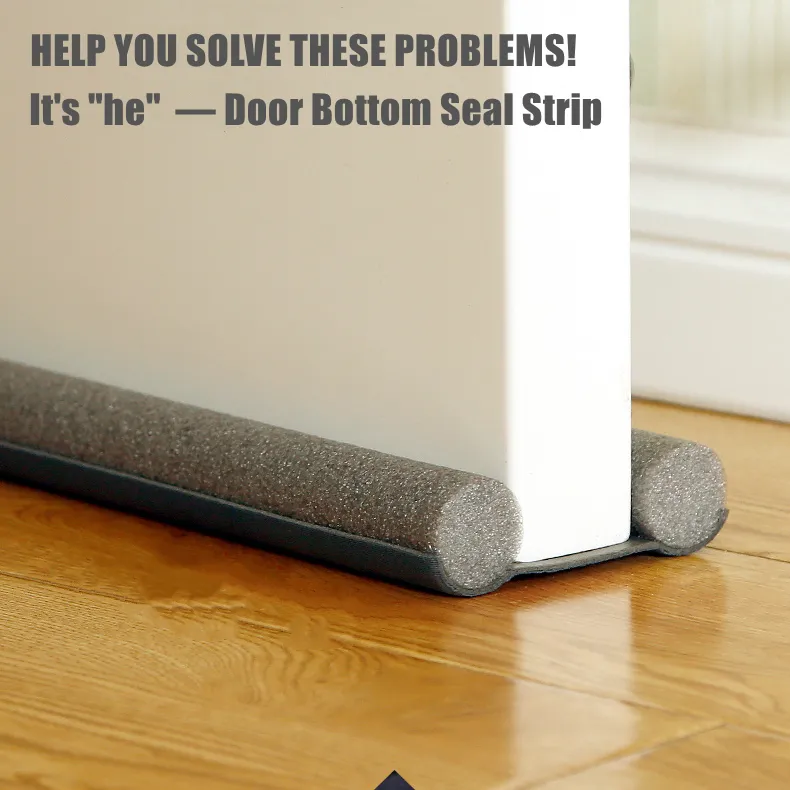

Hebei Qiuzhuo door bottom noise seal97People have read

Introduction...

Tags:

Next: What sets the Dexi doormat apart from traditional options is its aesthetically pleasing designs. Available in a variety of styles, patterns, and colors, these doormats can complement any home decor theme, from modern minimalist to classic rustic. Whether you prefer bold graphics that make a statement or subtle, elegant designs that blend seamlessly with your entryway, there is a Dexi doormat that will fit your vision. This ability to merge functionality with fashion makes it a favored choice for homeowners who wish to express their personality right from the front door.

dexi doormat

Latest articles

wood step edge trimIn summary, multifunctional water absorbing non-slip mats are an essential addition to any home. With their ability to absorb moisture, provide safety, and enhance aesthetics, they cater to a wide range of practical needs. As consumers increasingly seek products that combine style with functionality, these mats stand out as a smart investment for ensuring a safer and more comfortable living space. In a world where convenience is key, the multifunctional water absorbing non-slip mat is undoubtedly a product that should not be overlooked.

...

Read More

wood step edge trimThe Benefits of Anti-Static Mats for Office Chairs

...

Read More

One of the biggest advantages of super absorbent non slip mats is their ability to soak up water, dirt, and debris. Made with a special blend of materials, these mats are designed to quickly absorb moisture so that your floors stay dry and safe. This is especially useful in high traffic areas such as entryways, bathrooms, and kitchens where spills and messes are common.

wood step edge trim...

Read More

Popular articles

Understanding Garage Door Rubber Bottoms Importance and Maintenance

, - ,

Additionally, thick cushioned bathtub mats are eco-friendly options available on the market. Many brands are now using sustainable materials that are free from harmful chemicals, which not only benefits the environment but also ensures that your home remains a safe space for your family.

Conclusion

3. Pest Prevention Pests such as rodents and insects are often looking for warm havens to nest and breed. Gaps around the garage door can serve as entry points for these unwanted guests. By sealing the top and sides of the garage door, you create a barrier that keeps pests at bay, safeguarding your garage and the items stored within it.

Conclusion

Latest articles

-

Round anti-slip rug underlays are incredibly versatile and can be used on various flooring types. Whether you have hardwood, tile, laminate, or carpet, there is an underlay option available that will work seamlessly with your flooring. Furthermore, their round shape makes them ideal for any decor, ensuring that they do not detract from the design aesthetics of the room. Instead, they provide a subtle base that enhances the overall look while serving a functional purpose.

-

When it comes to home improvement and energy efficiency, many homeowners overlook the importance of sealing their windows properly. One of the most effective solutions for this issue is the use of silicone strips. These versatile, rubber-like materials can significantly enhance the performance of windows, ensuring that they are not only aesthetically pleasing but also energy efficient. This article will delve into the benefits of silicone strips for windows and why they are a smart investment for any homeowner.

-

Conclusion

-

MAT drains are essentially geocomposite drainage systems that combine several materials to facilitate effective water drainage. They typically consist of a perforated core wrapped in a filtering geotextile that prevents the ingress of fine particles while allowing water to flow freely. The installation of MAT drains often occurs in areas prone to high groundwater levels or excessive rainfall, where the risk of soil saturation and hydrostatic pressure is elevated.

-

The Long Brush Door Sweep A Perfect Solution for Energy Efficiency

-

Maintenance is also minimal, as these mats can be cleaned with a hose or pressure washer to remove dirt and debris. For stubborn stains or mold, a mild detergent can be used without damaging the mat, ensuring that your pool deck remains safe and appealing throughout the summer season.

Links

- Heavy-Duty Slurry Pump

- There is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

- Abrasive.

- Materials of Construction

- Slurry Pump

- Slurry Pump VS Mud Pump

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

- - Pumping the final product in a process

- Dredge Pump

- Mud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

- Firstly, analysing your duty helps us to determine whether you are using the type and size of pump best suited to your needs. Cavitation can occur due to surges; a very effective way to solve this problem is to install a choke on the pump head to increase the pressure on the casing, which then absorbs the surge, or to add a choke to the output to reduce the surge.

- What is a slurry pump?

- The most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

- Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

- Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

- What is a slurry?

- Slurry Pump

- Dredge Pump Features

- Slurry Pump

- There is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

- The Difference Between Flushing And Quenching in Slurry Pump Seals

- Slurry pump considerations

- Centrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

- Slurry Pump

- The construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

- The main objective of all flush water programmes is to prevent contamination of the seals by pumped water.The flush water programme for boxes is therefore very similar to the flush water programme for mechanically sealed boxes. However there are still some obvious mechanical differences. The most notable difference is the addition of a seal (packing) between the inlet and outlet limits. This minimises the amount of flushing fluid consumed.

- reduce the discharge pressure of the pump to the lowest possible point, and.

- Consider the pump components

- There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

- Centrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

- Pumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

- Consider the pump components

- Materials of Construction

- TL FGD Pump

- Discharge ports can be placed at 45 degree intervals and oriented in up to 8 different positions depending on your needs.

- Selecting And Operating A Slurry Pump

- There are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

- Conveying medium

- If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

- The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

- - Pumping the final product in a process

- Low slurry flow rates

- Choosing Dry Slurry Pumps Versus Submersible Slurry Pumps

- Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

- Pumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

- These mud pumps can pump not only sand, but also more mud. They are very effective in pumping all forms of mud, gravel, concrete, slurry, slush, etc.

- Slurry pump construction materials

- WZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

- Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

- Types of slurry pumps