Strengths and Weaknesses

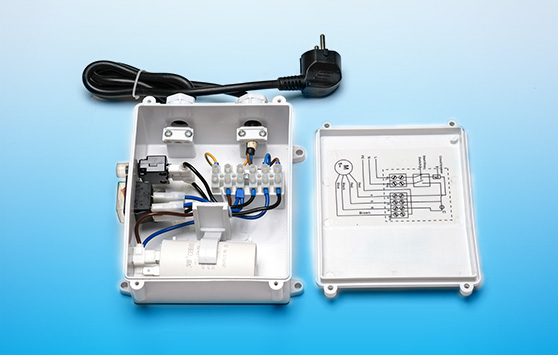

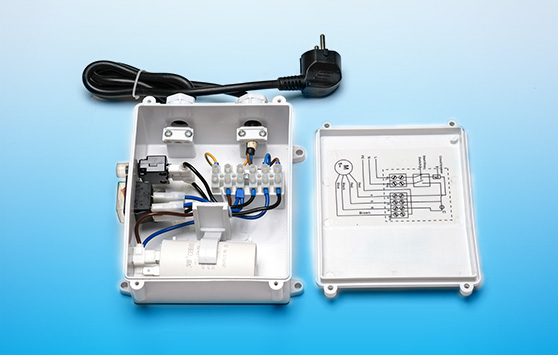

This article delves into the essence of control boxes, exploring their design, functionality, and the critical role they play across various industries. Prepare to uncover the intricacies of these pivotal devices and learn how to select the perfect control box to meet your specific requirements.

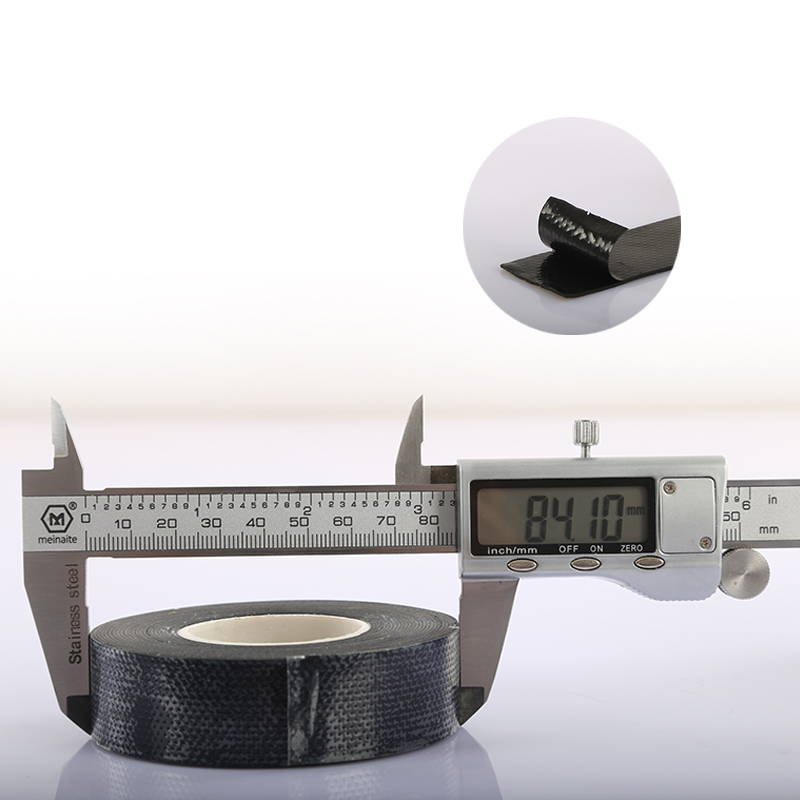

The most common type of electrical insulation tape used in the home, vinyl tape is used for insulation, protection from moisture, and repairing minor nicks and cuts.

With all of the new products and electrical insulation kits currently on the market, the use of conventional electrical tapes has gone down. As a result, electricians today may not possess the taping skills that once were such an important part of their predecessors' work. Nevertheless, there is still good reason to master this craft — especially for those times when repairs are needed quickly and other products are simply not available.

They are effective at preventing heat loss in colder climates and heat gain in warmer climates, which can significantly reduce energy costs They are effective at preventing heat loss in colder climates and heat gain in warmer climates, which can significantly reduce energy costs

They are effective at preventing heat loss in colder climates and heat gain in warmer climates, which can significantly reduce energy costs They are effective at preventing heat loss in colder climates and heat gain in warmer climates, which can significantly reduce energy costs expansion joint foam strip. This makes them an ideal choice for buildings with strict energy efficiency requirements.

expansion joint foam strip. This makes them an ideal choice for buildings with strict energy efficiency requirements.The strength of Black Flex Tape lies in its unique design. It features a durable surface that is both thick and flexible, allowing it to conform to different shapes and surfaces. The adhesive backing is designed to create a powerful bond, promoting durability and longevity. One of the tape’s standout features is its waterproof quality, which ensures that repairs can withstand moisture and harsh weather conditions. This makes it suitable for outdoor repairs, such as sealing cracks in gutters or repairing outdoor furniture.

In general, though, most types of electrical tape will start to show signs of degradation at around 70°C.

3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

Polyethylene Rubber Tape has several important characteristics:

33 kv ht insulation tape.