Characteristics of High Voltage Insulation Tape

Self-bonding rubber tape, often referred to merely as rubber tape, is an innovative solution that has transformed the way we think about sealing, insulating, and repairing various materials. This unique type of tape is characterized by its ability to bond to itself without the need for adhesives, making it an invaluable tool in numerous applications, from electrical work to plumbing and beyond.

Conclusion

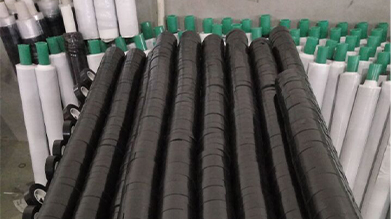

130c linerless rubber splicing tape. Whether used for electrical insulation, sealing, or bonding, the 130c% linerless rubber splicing tape provides a reliable and long-lasting solution.

The 130C linerless rubber splicing tape is made from a special formulation of rubber that can withstand temperatures up to 130 degrees Celsius. This makes it ideal for use in high-temperature environments where other types of tape may fail. The tape is also highly flexible, making it easy to work with and apply to different surfaces. Its linerless design allows for easy application and removal, without leaving any residue behind.

Safety and Compliance

3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

Moreover, the use of flame retardant tapes is not only influenced by safety concerns but also by regulatory compliance. Many countries have enacted stringent regulations governing the flammability of materials used in various applications. Using flame retardant tapes ensures adherence to these standards, thereby avoiding penalties and ensuring the safety of products in the market. Manufacturers that incorporate these tapes into their processes can also advertise their commitment to safety, potentially enhancing their reputation and appeal to customers.