Current location:pvc edge banding thickness >>Text

pvc edge banding thickness

Hebei Qiuzhuo door bottom noise seal8699People have read

Introduction...

Latest articles

pvc edge banding thicknessSelecting the appropriate size for edge banding tape is essential for achieving a seamless look and optimal functionality. A poorly fitting tape can result in gaps or an uneven surface, undermining the overall aesthetic of the project. Here are some key considerations when choosing the right size

...

Read More

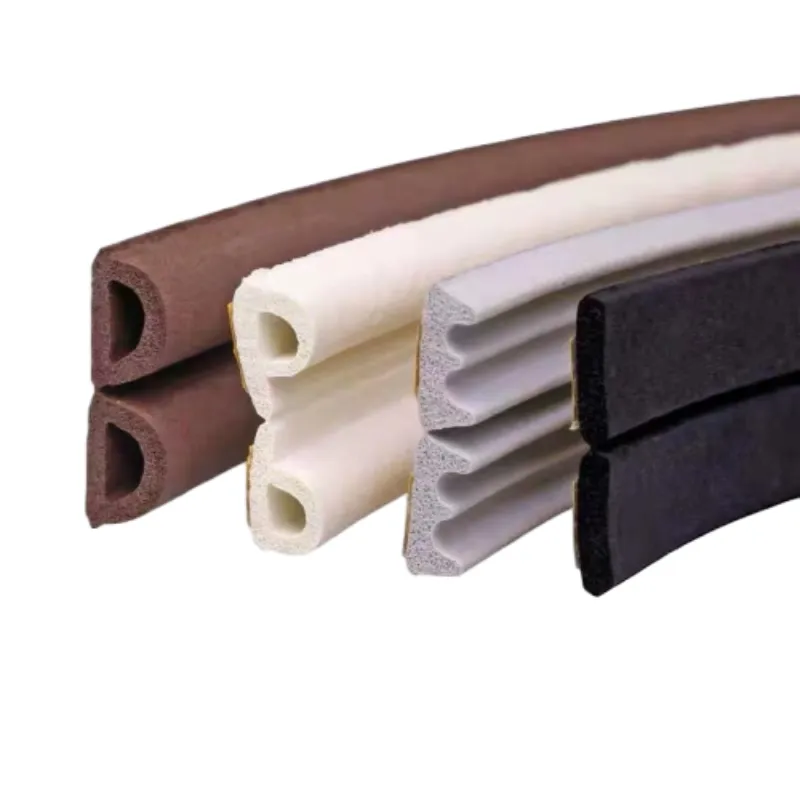

pvc edge banding thickness5. Versatility These weatherstrips can be used not just on external doors but also on interior doors, windows, and even garage door seals. Their versatility makes them an excellent investment for improving the overall energy efficiency of your property.

...

Read More

pvc edge banding thicknessComfort and Support

...

Read More

Popular articles

Navigating through daily life can be a challenge for individuals who rely on wheelchairs. One significant yet often overlooked aspect of wheelchair accessibility is the flooring surface where these users maneuver. Non-slip wheelchair mats are critical components that enhance safety, provide comfort, and improve the overall experience of wheelchair users in various environments.

Benefits of Non-Slip Chair Mats

O Mistério do Que Passa Debaixo da Porta

In homes and commercial spaces alike, safety should always be a top priority, especially in areas where slips and falls are a real risk. Steps can often be a significant hazard, particularly when they are exposed to environmental elements such as rain, snow, or even spills. This is where anti-slip mats come into play, serving as an essential safety feature that can greatly reduce the likelihood of accidents.

Replacing an oven door gasket is a manageable DIY project that can enhance your oven's performance and efficiency. Regularly checking your gasket and replacing it when necessary can save you both energy and money in the long run. With the right tools and a little patience, you can ensure your oven operates at its best, and cooking becomes a more enjoyable experience. When in doubt, always refer to your oven's user manual or consult a professional for assistance. Happy cooking!

Conclusion

Latest articles

-

Understanding the Importance of Non-Slip Bath Mats

-

Tuotteen asentaminen on erittäin yksinkertaista, ja useimmissa tapauksissa se ei vaadi erityisiä työkaluja. Valitse vain oikean kokoinen hyönteisten estäjä, joka sopii oviaukkoosi, ja seuraa valmistajan ohjeita. Monet hyönteisten estäjät tarjoavat myös mahdollisuuden mukautettuun leikkaamiseen, joten voit varmistaa täydellisen istuvuuden jokaiseen oveen.

-

When it comes to interior design and construction, aesthetics and functionality go hand in hand. One of the essential yet often overlooked aspects of interior finishing is the protection of drywall corners. This is where drywall corner protectors come into play. These handy accessories not only enhance the appearance of walls but also extend their durability and lifespan.

-

Protection des bords extérieurs L'importance des protecteurs de bords

-

-

Safety for Corners of Tables Ensuring a Secure Environment

Links

These types are made with a metal outer case and a PTFE lip. They are suitable for a wide range of temperatures from -90 °C to +260 °C.These lip seals can also be used for higher pressures of up to 10 bar (special types up to 25 bar) and rotational speeds of up to 40-45 m/s. Certain grades of PTFE are suitable for use in pharmaceutical and food applications. One important point is that PTFE lip seals do require a shaft with a harder, smoother finish.

- One of the key advantages of PU oil seals lies in their chemical resistance. They can effectively resist degradation from exposure to a wide range of chemicals, including oils, greases, solvents, and even some acids. This property not only extends the lifespan of the seal but also prevents contamination of the machinery, ensuring consistent performance.

High oil resistance and good abrasion resistance - When replacing the valve cover gasket, it is crucial to choose a high-quality product like the 5.9% Magnum gasket to ensure a proper seal and long-lasting performance. It is also essential to follow the manufacturer's instructions and torque specifications to prevent over-tightening or under-tightening the valve cover bolts, which can lead to leaks or damage.

Jam the flywheel ring gear to prevent the engine turning while you undo the crankshaft pulley bolt.

In conclusion, wheel hub oil seals and steering oil seals are essential components in automotive systems, contributing to the efficiency, safety, and reliability of the vehicle. Understanding the significance of these seals and their proper maintenance is crucial for optimizing the performance and longevity of the wheel hubs and steering mechanisms.

9 Factors for Selecting Oil Seals

The garter spring is located at the end of the primary sealing lip and used to apply pressure to the sealing lip against the shaft. Common garter spring material types are:

They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment

They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment rubber flange gasket. This makes them a convenient and efficient sealing solution for maintenance and repair applications.

rubber flange gasket. This makes them a convenient and efficient sealing solution for maintenance and repair applications.Importance of Quality Oil Seals in Automotive Applications:

Use a flat paint scraper, or the smooth side of an old hacksaw blade, to remove very carefully all traces of carbon and old gasket from both faces.

spark plug o ring. It is important to regularly inspect the O-ring during routine maintenance checks and replace it if necessary. A worn or damaged O-ring can lead to oil leaks, engine misfires, and other issues that can affect the performance of the vehicle.

Look at the end of the sump. If you cannot see clearly whether you need to remove the engine, consult a car service manual or dealer.

Oil seal performance is affected by not only the type and material of the selected oil seal, but also a variety of other factors, such as operating conditions, total eccentricity, rotational speed, the substance to be sealed, and lubrication conditions.

Figure 9 shows items relating to oil seal characteristics.