Understanding Butyl Rubber

It’s important to consider the specific requirements of the application, including temperature range, mechanical stress, chemical exposure, electrical properties, and budget when selecting the most suitable carrier material for adhesive tapes. Each material has its advantages and is chosen based on the specific demands of the application.

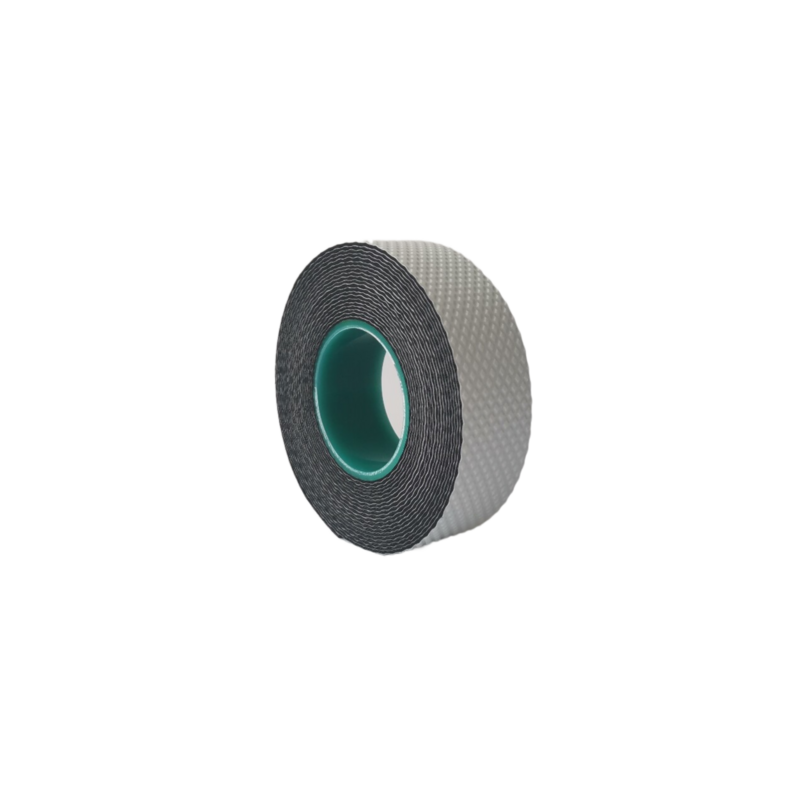

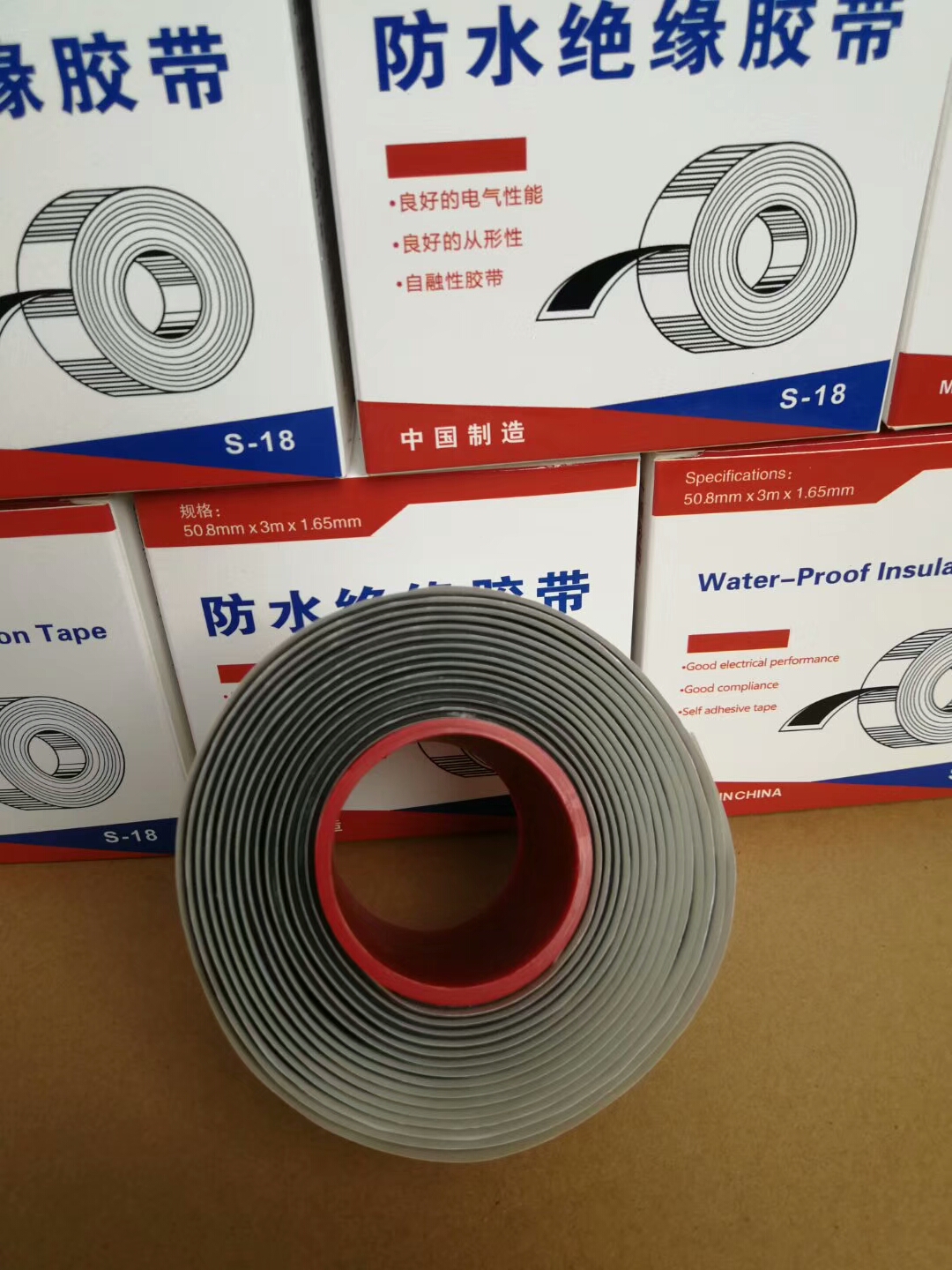

2. Durability Made to withstand extreme temperatures and harsh environments, self-fusing rubber tape maintains its effectiveness and integrity over time. Its resistance to abrasion, UV radiation, and chemical exposure ensures longevity, even in challenging conditions.

The vibrant colors and adhesive properties of the tape make it a fun and easy material to work with The vibrant colors and adhesive properties of the tape make it a fun and easy material to work with

The vibrant colors and adhesive properties of the tape make it a fun and easy material to work with The vibrant colors and adhesive properties of the tape make it a fun and easy material to work with colored pvc tape. Crafters can use PVC tape to create decorative borders, accents, or patterns on various surfaces. The tape can also be easily cut, folded, and layered to achieve different artistic effects.

colored pvc tape. Crafters can use PVC tape to create decorative borders, accents, or patterns on various surfaces. The tape can also be easily cut, folded, and layered to achieve different artistic effects. Additionally, it exhibits excellent UV, ozone, and chemical resistance, ensuring its longevity in outdoor or chemically aggressive settings Additionally, it exhibits excellent UV, ozone, and chemical resistance, ensuring its longevity in outdoor or chemically aggressive settings

Additionally, it exhibits excellent UV, ozone, and chemical resistance, ensuring its longevity in outdoor or chemically aggressive settings Additionally, it exhibits excellent UV, ozone, and chemical resistance, ensuring its longevity in outdoor or chemically aggressive settings silicone insulation tape.

silicone insulation tape.

The Benefits and Importance of Butyl Weather Stripping

Types of Control Boxes

rubber tape for leaks. It can be used to patch up small holes in hoses, seal around windows and doors to prevent drafts, and even serve as a temporary fix for leaky roofs. Its weatherproof nature means it can withstand various climate conditions, making it suitable for indoor and outdoor applications.

rubber tape for leaks. It can be used to patch up small holes in hoses, seal around windows and doors to prevent drafts, and even serve as a temporary fix for leaky roofs. Its weatherproof nature means it can withstand various climate conditions, making it suitable for indoor and outdoor applications.Electrical Applications

However, like any product, it is important to remember that while Flex Tape is highly effective for many applications, it may not be suitable for every situation. For example, for structural repairs or tasks that require significant strength, traditional methods such as welding or mechanical fasteners should be considered.

Its specific features include

In warehouses, implementing clear, marked pathways using floor tape can streamline operations. Workers can easily navigate the space, reducing the time spent searching for items or traversing hazardous areas. This improved efficiency can ultimately lead to increased productivity and reduced operational costs.

Busbars are conductive material strips used to distribute electrical energy within power distribution systems. Given the high voltage levels these systems often operate under, the insulation of busbars becomes paramount. Proper insulation safeguards against electrical arcing, shorts, and leakage currents, which can lead to catastrophic failures and safety hazards.

Key Benefits of Red Insulation Tape

Material Quality

Advantages of Polyethylene:

Our rubberized tape is non-hazardous and non-toxic under normal temperatures and storage conditions and it meets industry-based standards for development and production. We provide Safety Data Sheets and Technical Data Sheets (technical information on the chemical formulations used rubber tape manufacturing), and safety guidelines and regulations with each order. In addition, we offer technical support on all our products.

Shouldn’t snap when you wrap.

yellow and green electrical tape. The bright yellow stands out against the green background, making it easy to distinguish between different types of wires, connections, or circuits. This color combination is particularly useful in complex electrical systems where multiple wires need to be identified quickly and accurately.

varnished cambric tape. The woven fabric provides a barrier between conductive elements, helping to prevent short circuits and other electrical malfunctions. This can help to ensure the safe and reliable operation of electrical systems.