Current location:outdoor non slip mats for pool area >>Text

outdoor non slip mats for pool area

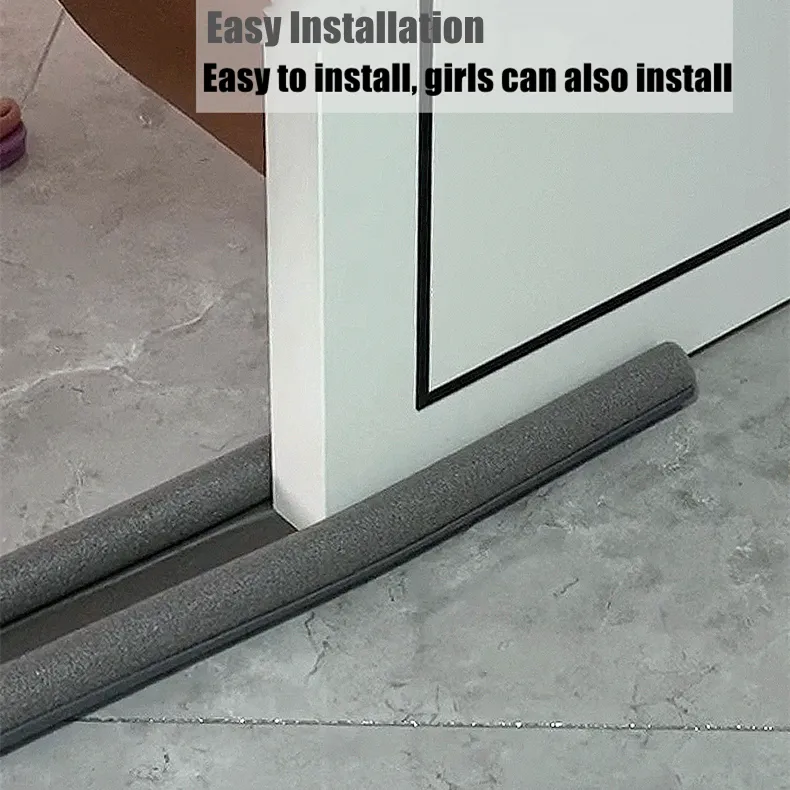

Hebei Qiuzhuo door bottom noise seal62874People have read

Introduction...

Tags:

Previous: One of the primary benefits of round non-slip mats is their application in the kitchen. Kitchens are notorious for spills caused by water, oil, or food, which can create hazardous conditions. By placing a round non-slip mat near the sink or cooking areas, individuals can safeguard themselves from falling. The mat provides a stable surface, which is crucial when engaged in activities such as chopping vegetables or washing dishes. Moreover, these mats are easy to clean, often simply requiring a quick wipe down to remove any spills or dirt, thus maintaining a hygienic cooking environment.

round non slip mat

Latest articles

outdoor non slip mats for pool areaIn conclusion, anti-slip step mats are an invaluable addition to any environment where safety and comfort are priorities. By preventing slips, enhancing comfort, and providing aesthetic appeal, these mats play a crucial role in promoting safer and more inviting spaces. Investing in quality anti-slip mats is a practical decision that can lead to significant long-term benefits, making them an essential consideration for both homeowners and business owners alike.

...

Read More

outdoor non slip mats for pool area2. Visibility and Safety The color white is naturally bright, making it easier to notice any dirt, spills, or hazards on the mat's surface. This increased visibility encourages users to keep the area clean and maintain safety standards, reducing the risk of accidents. Furthermore, a clean white mat invites a sense of hygiene, making it ideal for areas such as food preparation zones.

...

Read More

outdoor non slip mats for pool area- Bamboo or Wood For a more natural aesthetic, bamboo bath mats offer a unique look while providing a water-resistant surface. They are less slippery and have their own charm but may require more maintenance.

...

Read More

Popular articles

What is a Brush Seal Door?

3. Noise Reduction In addition to blocking drafts, oversized weather stripping can serve as a sound barrier, minimizing noise pollution from outside. This is particularly advantageous for homes located in busy urban areas or near schools and parks, allowing for a more peaceful living environment.

5. Aesthetics and Customization Anti-slip mats are available in various styles and colors, allowing for personalization according to the owner’s taste. This means that safety does not have to come at the expense of style. Businesses can also use branding elements in their mat designs, reinforcing their identity while ensuring safety.

- 3. Install the New Gasket Start by positioning the new gasket in place along the edge of the oven door or cavity. Make sure the gasket is straight and evenly aligned before securing it in place. Depending on the type of gasket, you may need to reattach it with screws, clips, or adhesive. Follow the manufacturer's instructions for proper installation.

1. Enhanced Insulation By sealing the gap under your garage door, you can improve insulation, which can help maintain a stable temperature inside your garage. This is particularly beneficial if your garage is attached to your home.

While the primary function of corner and edge protectors is to shield walls, they also offer additional benefits

Latest articles

-

Design Considerations

-

-

Conclusion

-

A door draft sweep is a simple yet effective solution designed to seal the gap between the bottom of a door and the floor. Typically made from materials such as rubber, foam, or silicone, these sweeps create a barrier against cold air entering in the winter or hot air in the summer. They can be either attached to the door itself or installed as a separate component, ensuring that any gaps in the door's lower edge are adequately sealed.

-

The durability of rubber cannot be overstated. Unlike metal surfaces, which can corrode or wooden floors that may rot or splinter, rubber mats endure the test of time and harsh conditions, such as heavy weights, UV rays, and extreme temperatures. They require minimal maintenance and are easy to clean—a simple rinse with water or a damp cloth usually suffices.

-

Installing a rain guard is a relatively simple process that many homeowners can manage on their own. Here are some basic steps to consider

Conclusion

On average, the cost to build a metal garage ranges from $3,000 to $20,000 or more, depending on the factors mentioned. A simple 12x24-foot metal garage can start at around $5,000, while more expansive designs with custom features can climb to $15,000 or higher. It's essential to get multiple quotes from different contractors to find the best deal while ensuring quality workmanship.

Cost-effectiveness is another key reason steel frame barn houses are on the rise. While the initial investment may seem higher compared to traditional wooden structures, the long-term savings become apparent through decreased maintenance costs and insurance premiums. Steel buildings are often rated more favorably by insurance companies due to their durability and resistance to fire, which can lead to lower premiums. Additionally, the rapid construction time associated with steel frame buildings decreases labor costs, making it an economically viable option for many.

The Advantages of Premade Shed Frames An Efficient Solution for Storage Needs

This means quicker access to your warehouse and lower overall construction expenses.

Urban agriculture in buildings also presents an opportunity for community involvement and local engagement. By integrating food production into the urban landscape, cities can encourage residents to participate in growing their own food, fostering a sense of community and reducing food insecurity. Educational programs can be developed around these initiatives, teaching urban dwellers about sustainable practices, nutrition, and the importance of local food systems.

2. Ventilation and Natural Light Including windows or vents in the design can help prevent the buildup of moisture, promoting a healthier environment for stored items or tools. Natural light can also make the shed more pleasant to use.

We always like to highlight the superior strength and durability of steel over other building materials. Warehouses often are used for commercial and industrial spaces, meaning that they contain heavy objects or heavy machinery that if mishandled can cause significant structural damage. Steel buildings are better able to withstand this type of impact damage.

Enhanced Security Features

Farm storage buildings are essential components of modern agriculture, serving as a critical resource for farmers seeking to optimize their operations and manage their produce effectively. With the increasing demand for food security and sustainability, investing in robust storage solutions has never been more important. This article explores the various aspects and advantages of having dedicated storage facilities on farms.

- Natural Materials Use materials like wood, stone, and metal in your decor to complement the barn’s structure. Wooden floors, stone countertops, and metal light fixtures can beautifully harmonize with the industrial feel of the metal barn.

The Essential Role of Farm Buildings in Modern Agriculture

While premade shed frames come in standardized sizes and shapes, many manufacturers offer customization options to suit individual needs. Homeowners can select specific dimensions, window placements, door styles, and even roofing materials. This level of flexibility allows you to create a shed that meets your unique storage requirements while enhancing your property’s curb appeal.

Long-Term Considerations

Conclusion

In conclusion, premade metal buildings offer a host of benefits that make them an attractive choice for various applications. The quick construction times, cost savings, durability, versatility, eco-friendliness, and minimal maintenance all contribute to their rising popularity. As the demand for efficient and effective building solutions continues to grow, premade metal buildings are proving to be a smart investment for businesses and individuals alike. Whether for personal projects or large-scale commercial endeavors, these modern structures are paving the way for the future of construction.

Another significant benefit is the versatility of design that steel offers. With advancements in pre-engineered steel buildings, homeowners have nearly limitless options in terms of size, shape, and layout. Steel can be customized to fit various architectural styles, allowing for a seamless integration into the surrounding landscape. Whether one desires a traditional barn aesthetic with rustic accents or a sleek, modern design, steel can accommodate these visions with ease. The open floor plans often associated with barn homes provide a spacious and functional living environment, making them ideal for families or those who entertain frequently.

steel barn homes

Creating a Metal Workshop Essential Plans and Considerations

Moreover, the ability to expand or modify a metal building easily adds to its appeal. As businesses grow or needs change, metal structures can be adapted without the need for extensive renovations. This scalability is particularly attractive to companies looking to minimize long-term investment risks.

1. Affordability One of the primary reasons behind the growing popularity of barn metal is its cost-effectiveness. Compared to traditional building materials like wood or bricks, barn metal is significantly cheaper, allowing builders to complete projects without breaking the bank. This affordability extends to insulation costs—metal structures can be designed to be energy-efficient, reducing long-term overheads.

Security is a top priority for anyone looking to store valuable equipment and tools. Metal sheds provide an added layer of protection against theft and vandalism. The robust nature of metal construction makes it extremely difficult to break into compared to wood or plastic alternatives. Many manufacturers equip their metal sheds with locking mechanisms and reinforced doors, ensuring that your belongings remain safe and secure. For those who require an extra level of protection, some models allow for the installation of security systems or alarms, further safeguarding your investments.

Considerations

Proper waste management is another vital component of maintaining hygiene in a steel frame chicken coop. Accumulated manure can be a breeding ground for bacteria and parasites, increasing the risk of disease transmission. Implementing an efficient waste removal system is crucial for keeping the coop clean and reducing the spread of infections.

Building a Metal Garage with Office A Smart Solution for Modern Needs

Although the initial investment in a steel poultry shed may be higher than that of traditional wooden structures, the long-term savings are substantial. Steel sheds require minimal maintenance due to their resistant properties. Additionally, their longevity means that farmers will spend less on replacements over time. With the rising costs of raw materials and labor, utilizing steel for poultry housing becomes a more financially prudent choice for farmers looking to maximize their profits.

Steel warehouse structures come in various models catering to different needs. Some popular options include

Flexibility and customization are also inherent advantages of industrial prefab buildings. Modern prefab manufacturing techniques allow for a high degree of customization, enabling businesses to tailor their building designs to meet specific operational needs. Whether a company requires a large warehouse, an office space, or a combination of both, prefab structures can be designed to accommodate various configurations and functionalities. This adaptability is particularly beneficial for industries experiencing rapid growth or fluctuating demands.

Sustainability is becoming increasingly important in business operations, and metal garages offer a more eco-friendly alternative to traditional construction. Steel is one of the most recycled materials globally, and opting for a metal structure contributes to reducing waste. Additionally, the energy efficiency of metal garages helps lower carbon footprints, aligning with corporate social responsibility goals.

Since pre-engineered metal buildings are 100% custom, your warehouse can be as long, wide, and tall as your business needs. The size is at the mercy of your company’s budget and lot dimensions.

3. Size of the Home Pricing will vary dramatically based on the square footage. A small, basic steel barn home may start at around $30,000, while larger models can range upwards of $100,000 or even more, depending on additions and custom features. The size also dictates not just construction costs, but also the logistical expenses of land preparation and utility installation.

In summary, factory steel buildings are a robust and versatile solution for modern industrial needs. Their durability, cost-effectiveness, design flexibility, energy efficiency, rapid construction capabilities, and safety make them a preferred choice for many businesses. As industries continue to evolve, the advantages of steel construction are likely to keep these facilities at the forefront of the industrial landscape. Businesses looking to invest in new facilities should consider the long-term benefits that factory steel buildings have to offer.

In today's world, sustainability is more important than ever. A metal workshop that includes living quarters can also incorporate eco-friendly practices. Using sustainable materials, implementing solar panels, and creating recycling stations for metal scraps are just a few ways to ensure that craftsmanship does not come at the expense of the environment.

Steel-framed buildings are incredibly versatile, making them suitable for various agricultural applications. Whether it’s a barn for cattle, a poultry house, or a storage facility for equipment and grain, steel structures can be customized to meet specific requirements. The open-span design of steel buildings allows for large, unobstructed interior spaces, making it easier to accommodate machinery, livestock, and crops. Farmers can adapt the layout to suit their operations, adding modular components as their needs change over time.

Prefab workshop buildings are manufactured off-site in a controlled environment before being transported and assembled at their final location. This process involves the creation of modular components, which can be quickly and efficiently assembled, resulting in a significant reduction in construction time compared to conventional building methods.

However, the journey within the metal garage is not without its challenges. Many aspiring musicians face the harsh reality of staying true to their vision amidst the pressures of the music industry. The struggle to balance personal commitments while pursuing their passion can often be daunting. Yet, the garage offers a safe space to hone their craft, away from the commercial spotlight. It is here that they cultivate their skills, craft their songwriting, and prepare for the inevitable transition to larger venues. The journey, steeped in passion and resilience, often leads to remarkable success stories, with bands breaking out of their garage confines to captivate audiences worldwide.

Factors Influencing Costs

Incorporating ergonomic design principles can also enhance safety and productivity. For example, designing workspaces that minimize repetitive strain injuries or ensuring that equipment is easily accessible can improve overall employee satisfaction and efficiency.

Steel prefabricated warehouses are great alternative options for businesses that are in need of a warehouse fast. Since they have been prefabricated, all there is left to do is to install them. They are also more durable than a warehouse made from the ground up because the prefabricated materials are made with stringent standards. That means the prefabricated materials do not go out of the factory without a thorough quality check and control.

Technological Integration

Mobility and Flexibility

Cost-effectiveness is another crucial aspect that makes the pipe shed frame appealing. Traditional building methods often involve significant labor and material expenses, but the simplicity of pipe construction can reduce both. The components are readily available and can often be sourced locally, minimizing transportation costs. Additionally, the ease of assembly can reduce labor costs, as fewer skilled workers may be needed for installation. By cutting down on both material and labor expenses, businesses can allocate resources more efficiently, leading to improved profit margins.

pipe shed frame

1. Materials The choice of materials plays a significant role in pricing. Common materials for prefabricated warehouses include steel, aluminum, and concrete. Steel structures, while more expensive upfront, are known for their durability and lower maintenance costs, making them a solid long-term investment. On the other hand, less expensive alternatives might save initial costs but could lead to increased maintenance and operational costs over time.

3. Quick Assembly Most sheet metal garage kits are designed for quick and easy assembly, allowing you to set up your garage in a fraction of the time it would take to build a conventional structure. Many kits come with detailed instructions, making it simple for even novice DIYers to follow along.

In recent years, self-build metal garage kits have gained popularity among homeowners and DIY enthusiasts. These kits offer an excellent solution for those looking to add extra storage space, a workshop, or a vehicle garage without the hassle of traditional construction. This article will explore the benefits of opting for a self-build metal garage kit and how it can be a smart investment for your property.

The land where the steel workshop will be built must undergo thorough site preparation. This includes land clearing, leveling, and ensuring proper drainage and foundation work. Site conditions—such as soil type and existing infrastructure—can impact preparation costs. For instance, if the site requires extensive earthwork or reinforced foundations to support heavy machinery, this will add to the initial investment.