Current location:wind stopper for bottom of door >>Text

wind stopper for bottom of door

Hebei Qiuzhuo door bottom noise seal96265People have read

Introduction...

Tags:

Previous: Bovendien draagt een rubberen afdichting bij aan geluidsisolatie. In drukke buurten of appartementen kan geluidsoverlast een groot probleem zijn. Een goede afdichting zorgt ervoor dat geluidsgolven minder makkelijk binnenkomen of ontsnappen, waardoor de algehele leefomgeving rustiger wordt. Dit is vooral belangrijk voor mensen die thuis werken of ouders met jonge kinderen die een rustige omgeving nodig hebben.

door gap seal rubber

Next: Conclusion

Latest articles

wind stopper for bottom of door2. Comfort and Ergonomics Many anti-skid mats are also cushioned, providing a comfortable surface to stand on for extended periods. This is particularly beneficial in workplaces such as restaurants and factories where employees spend countless hours on their feet. The ergonomic design reduces fatigue and enhances productivity.

...

Read More

wind stopper for bottom of door3. Versatility Corner safety covers can be used in various settings, not just at home. They are ideal for daycare centers, schools, and other environments where children are present. Their installation can enhance safety in public spaces, ensuring a more secure environment for child interaction.

...

Read More

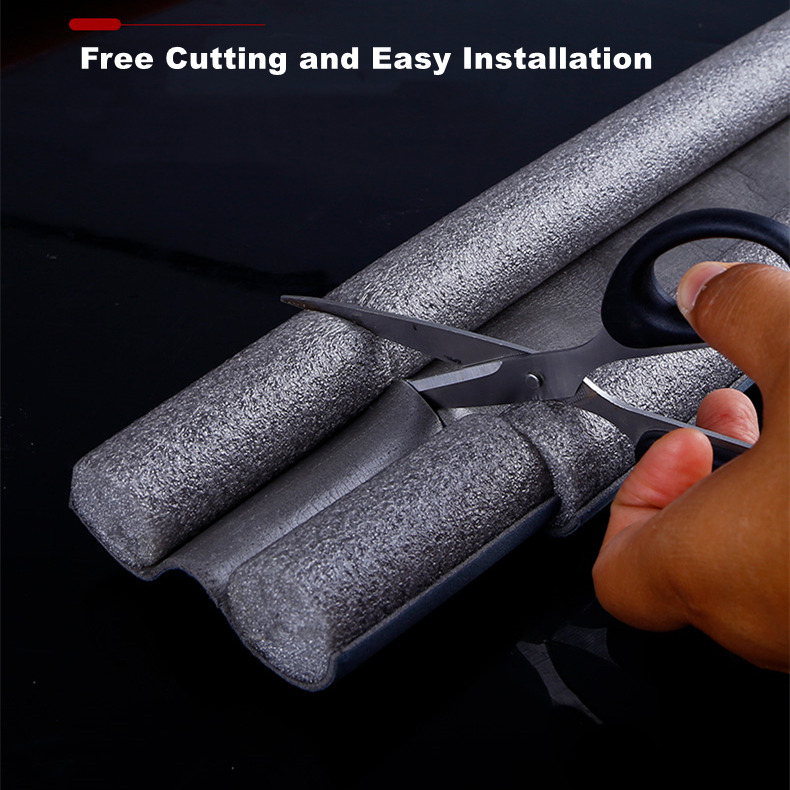

wind stopper for bottom of doorEasy Maintenance

...

Read More

Popular articles

In addition to its protective function, edge banding tape also contributes to the overall appearance of the furniture. It allows for a seamless and uniform finish, concealing the raw edges and creating a polished, professional look. The tape comes in a variety of colors, patterns, and textures, edge banding tape manufacturer to achieve diverse design styles and aesthetics.

Once everything is fitted properly, plug your oven back in or turn on the circuit breaker. Preheat the oven to a moderate temperature to test if it maintains heat effectively. Check around the edges of the door for any heat escaping, indicating a poor seal.

- .

1. Measure the Gap Use a ruler to measure the gap between the bottom of your door and the floor. This will help you determine the width and length of the weather stripping needed.

Furthermore, drain mats are easy to clean and maintain. Most mats are dishwasher safe, making it simple to keep them germ-free and looking like new. Regular cleaning also helps to prevent any odors from developing, ensuring a fresh and clean kitchen or bathroom environment.

Choosing the Right Draft Stopper

Latest articles

-

Historically, the use of water for medicinal purposes dates back to ancient civilizations such as the Greeks, Romans, and Egyptians. These cultures revered water for its cleansing and revitalizing properties. The Romans, in particular, were known for their opulent bathhouses, which featured various bathing options, including hot and cold baths, steam rooms, and other hydrotherapeutic facilities. The slip bath can be seen as a modern reinterpretation of this rich heritage, where individuals immerse themselves in a tranquil, often communal environment designed to promote relaxation and well-being.

-

5. Cost-Effective Solution Investing in non-slip mesh mats can be a cost-effective solution to preventing accidents and injuries. While the upfront cost may be modest, the potential savings from avoiding accidents, medical bills, and insurance claims can be substantial.

-

5. Wholesale Suppliers If you're working on a larger project or need edge banding in bulk, consider reaching out to wholesale suppliers or manufacturers. They often have competitive pricing and a broader selection of materials.

-

1. Enhanced Insulation One of the primary benefits of a 4-inch garage door seal is improved insulation. A wider seal can help to significantly reduce energy loss, keeping the garage and adjacent rooms warmer in winter and cooler in summer. This not only provides comfort but also contributes to energy savings and lower utility bills.

-

Maintaining a clean truck interior is crucial, especially for those who frequently use their vehicles for work or recreation. Rubber truck mats require minimal maintenance—an occasional hose-down or a quick wipe with soap and water is enough to keep them looking new. This easy cleaning process makes them a favorite among truck enthusiasts who want to maintain hygiene without the hassle of deep cleaning. Furthermore, rubber mats often come with raised edges, which serve to contain spills, preventing liquids from seeping into the vehicle's carpet.

-

Factors Affecting Prices

Links

- For pumping abrasive slurries, these types of pumps can also be made from specialised high-wear alloys. Hardened stainless steel is also a common choice for abrasive slurries.

- Repairable - target=_blank title=Rubber Lined Slurry Pumps>Rubber lined slurry pumps can be repaired by simply replacing the bushing.

- These conditions include

- Slurry Pump Impeller Type

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

- Rubber Lined Slurry Pump

- Mixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

- Will solids size pass through the pump?

- Step 4

- Dredge Pump

- Mechanical Seals

- >Dredge pumps are a special category of pumps used in the dredging process. Dredging is the process of transporting submerged sediments (usually sand, gravel or rock) from one area to another. Dredging takes place in the shallow waters of lakes, rivers or seas for land reclamation, dredging, flood control, new harbours or expansion of existing harbours. The various industries that use dredge pumps are therefore the construction industry, mining, the coal industry and the oil and gas industry.

- >Slurry pump impeller is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

- Process speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

- Series of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

- >Slurry Pump

- Types of slurry pumps

- As a pump supplier, Aier is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc. If you want to get more information about >best slurry pump wholesale, welcome to >contact us today or request a quote.

- >Slurry Pump

- Slurry pipe diameter.

- What is the best seal arrangement for the application?

- Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

- 2. All have vertical pumps and horizontal pumps and can convey slurry.

- Types of damage to slurry pumps

- Dredge Pump Features

- Vertical Slurry Pumps Pump Sewage More Efficiently

- factors-to-consider-when-choosing-a-slurry-pump

- The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- Slurry Pump

- Slurry Pump

- The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

- How much solids damage can the customer tolerate?

- How does a dredge pump work?

- How does a dredge pump work?

- The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

- Although the focus of slurry pumps is often on the size and percentage of solids to be pumped, in many applications corrosion resistance is also an important factor in material selection. In such cases, the material chosen must provide adequate resistance to erosion and corrosion.

- A target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

- Fine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

- factors-to-consider-when-choosing-a-slurry-pump

- What are the materials used to construct the pump?

- WA Heavy-duty Slurry Pump

- Slurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

- Improved flow control

- Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

- Depending on the abrasive nature of the slurry, it is important to select the ideal seal. Slurry pump seals should have a hardened surface made of silicon carbide or tungsten carbide. Vortex pumps use patented seal technology that utilizes a double mechanical seal setup and a separate seal flushing system. This allows the sealing surface to be kept cool at all times without causing the slurry to overheat the seal and crack the surface.

- Floor drainage

- How does a dredge pump work?

- Slurry Pump

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.