In conclusion, a single driveway gate can significantly enhance the security, privacy, and aesthetic appeal of your property. By choosing the right material, style, and ensuring proper installation, you can enjoy the numerous benefits that come with a beautifully crafted driveway gate for years to come. So, invest the time to find the perfect single driveway gate that suits your home and lifestyle.

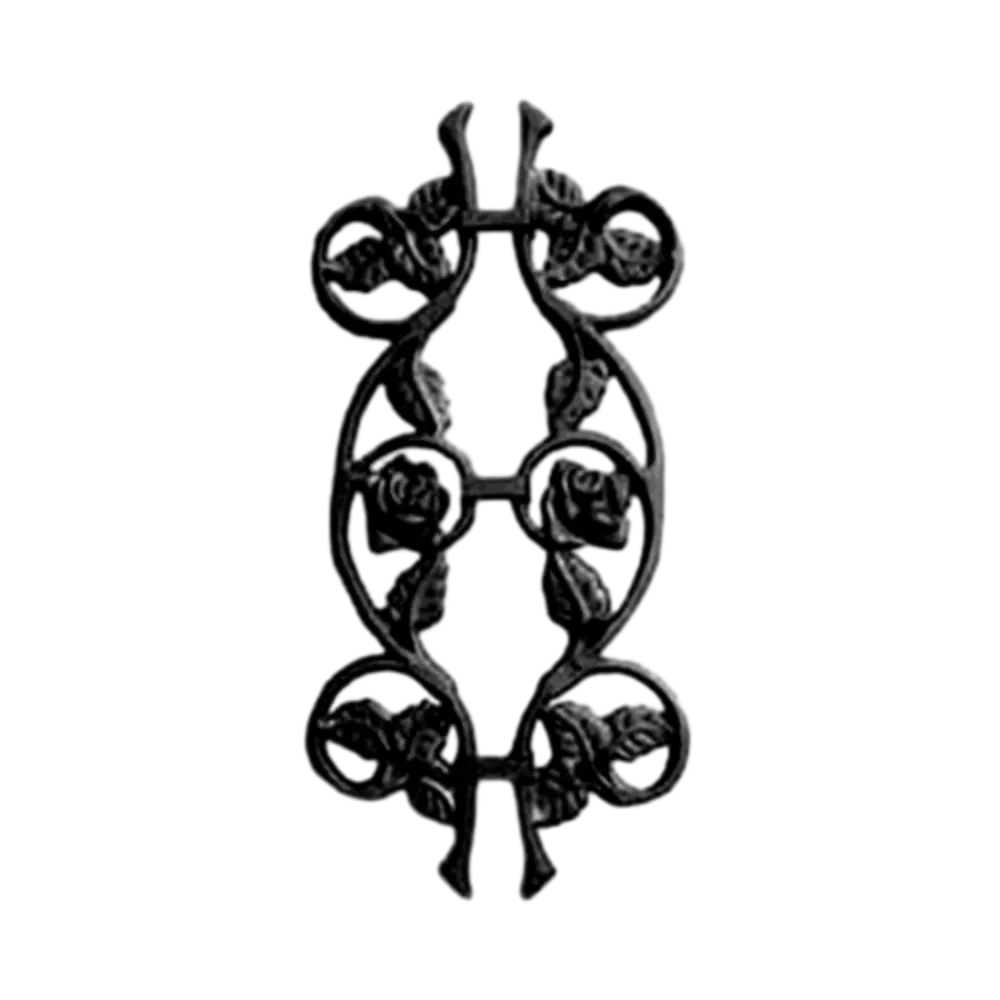

Main gate iron gate designs offer a wide array of possibilities, ranging from classic and ornate to modern and minimalist. The timeless charm of wrought iron, with its durability and malleability, allows artisans to craft intricate patterns and shapes, making each gate a unique piece of art. These designs often incorporate scrolls, leaves, floral motifs, or even customised elements reflecting the owner's interests or the heritage of the property.

There are many pros to using Ornamental Iron. Here are a few of them:

Our unique climate in Southern California can take a toll on our iron fences, as they are constantly exposed to humidity and moisture in the air, making iron victim to the process of oxidation. Over time, your iron fence will show the signs of oxidation with rust patches. Rust is the number one enemy of iron fences, and needs to be removed on the first signs of its appearance. This can be accomplished using a fine wire brush. Make sure to lay a tarp beneath the wrought iron fence to catch flakes, wear gloves, and carefully brush away all points of rust along the fence, paying special attention to the post and joints.

track and wheels for sliding door.

As we draw this conversation on aluminum vs wrought iron fence to a close and leave you to consider your fencing options, don’t forget that in Texas is your one-stop solution for premier wrought iron fences – and all things fence supply Austin, for that matter.

The term “wrought iron” often gets misused today to refer to any metalwork – often mild steel or cast iron – that’s designed to have the precise, intricate appearance of the classical wrought iron designs from the nineteenth century. However, to truly be wrought iron, the metal has to have been forged, heated, and hammered by a trained blacksmith, a process that’s become much rarer today than it was in the past. The hand craftsmanship that goes into its design and construction makes wrought iron a truly unique and special material today.

cast iron panels for railing. Unlike wood or other materials, cast iron does not require frequent staining or sealing to maintain its appearance. A simple cleaning with soap and water is typically all that is needed to keep these panels looking their best.

cast iron panels for railing. Unlike wood or other materials, cast iron does not require frequent staining or sealing to maintain its appearance. A simple cleaning with soap and water is typically all that is needed to keep these panels looking their best.One of the main uses of rod iron baskets is for storage. These baskets can hold a variety of items such as blankets, pillows, toys, magazines, and even firewood. They are perfect for organizing clutter and keeping your space neat and tidy. The open design of the baskets allows you to easily see what is inside, making it convenient to access your belongings.

- Track Type Ensure the wheels are compatible with the existing track system. Some tracks are designed for specific wheel types, so selecting the correct combination is crucial for seamless operation.

Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces

Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces

They can be cleaned with mild soap and water, and occasional waxing can help to keep them looking like new They can be cleaned with mild soap and water, and occasional waxing can help to keep them looking like new

They can be cleaned with mild soap and water, and occasional waxing can help to keep them looking like new They can be cleaned with mild soap and water, and occasional waxing can help to keep them looking like new