One of the significant advantages of using PP bag stitching machines is the cost-effectiveness they offer. By automating the stitching process, companies can minimize labor costs and increase output, translating to higher profitability. Furthermore, the precision of these machines reduces the likelihood of defects, ensuring that the bags are securely closed and thus enhancing product safety.

The versatility of the double stitch machine makes it suitable for a wide array of applications. It is commonly used in the manufacture of stretch fabrics, denim, and heavy-duty apparel. The machine’s ability to produce decorative stitching adds an aesthetic appeal to garments, making it a favorite among fashion designers seeking to innovate their collections. Additionally, its role is not confined solely to apparel; double stitch machines are also essential in upholstery, home textiles, and industrial applications, where stronger seams are necessary to withstand wear and tear.

Choosing the Right Heavy-Duty Quilting Sewing Machine

Conclusion

The Importance of Professional Upholstery Sewing Machines

Advantages of Long Arm Design

One of the key features of a woven sack sewing machine is its speed and efficiency. These machines are designed to work quickly and accurately, allowing for high volume production of woven sacks. This is essential for industries that require large quantities of sacks to package their goods for distribution.

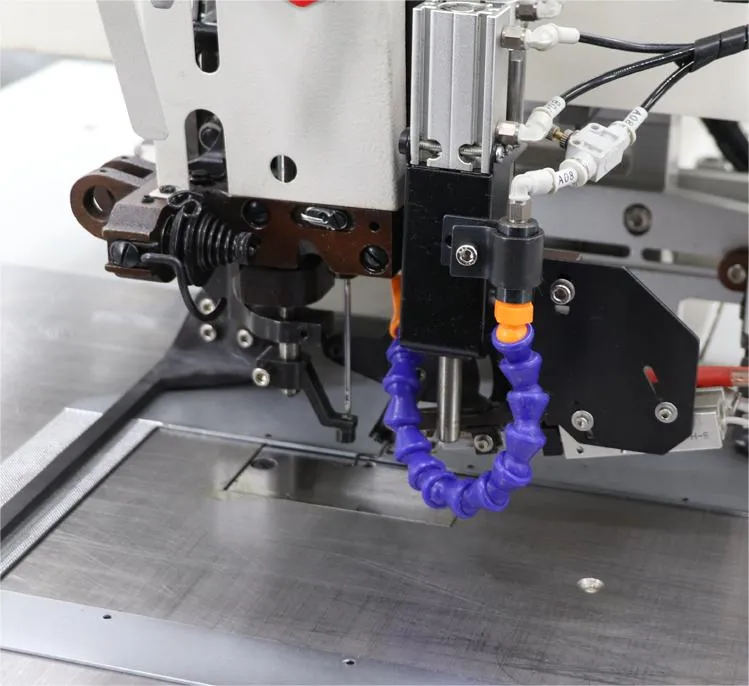

woven sack sewing machine

BENEFITS OF BUYING A HEAVY DUTY SEWING MACHINE

The role of bag seaming machines extends beyond mere convenience. They enhance productivity, reduce labor costs, and minimize waste while ensuring product integrity. In industries such as agriculture, food packaging, and pharmaceuticals, maintaining the quality of the contents is non-negotiable, and effective bag sealing is crucial to achieving this goal.

bag seaming machine