Front Door Base Seal – Waterproof Draught Excluder Strip for Door Bottoms

- Introduction: Understanding front door base seal

requirements and their growing significance - The science behind sealing: Draughts, energy loss, and the role of base seals

- Waterproofing strategies at the door threshold

- Comparative analysis: Market-leading door base products

- Customization options for unique entrances and advanced weather challenges

- Case studies: Real-world applications in residential and commercial contexts

- Conclusion: Elevate property efficiency and comfort with the right front door base seal

(front door base seal)

Introduction: Elevate Your Entrance with a Front Door Base Seal

Home and business owners increasingly recognize the importance of a robust front door base seal, not just as a basic add-on but as a critical element for optimizing property efficiency, comfort, and structure longevity. As survey data from the Energy Saving Trust (2023) highlights, up to 28% of heat loss in insulated buildings escapes through unsealed doorways and entry points. This blog thoroughly explores how a well-chosen base seal, supported by technologies such as multi-lip compression and silicone barriers, closes these energy-wasting gaps, underpins sustainability goals, and protects interiors against unpredictable weather. The need for effective sealing no longer revolves solely around stopping draughts; it encompasses insulation, waterproofing, security, and the rising demand for adaptable designs suitable for all property types.

The Science Behind Sealing: Draught Exclusion and Energy Optimization

The function of any door base draught excluder is rooted in fundamental physical principles. Air seeks equilibrium, so warm air inside a property will naturally leak through the path of least resistance — often under poorly fitted doors. According to research cited by the Building Research Establishment, a standard 2 mm gap on a typical entrance can equate to a 0.25 sq. ft. hole in the building envelope. When multiplied by the day's heating or cooling demands, unsealed doors could account for a disproportionate rise in energy bills—up to £85 per year in temperate regions like the UK, and significantly more in climates with extreme seasonal shifts.

The modern marketplace offers a range of materials — from classic brush-type excluders to high-tech TPE (thermoplastic elastomer) and silicone base strips — each with distinct properties for sealing and insulation:

- Brush excluders: Good for draught and dust prevention, yet less effective at blocking water ingress.

- Rubber and silicone blades: Excellent compressibility and pliability, serving well in both thermal and acoustic insulation.

- Magnetic and double-fin solutions: Provide a continuous seal even on slightly uneven floors.

Waterproofing at the Door: Defending Against Moisture Intrusion

A door base waterproof strip marks the frontline in protecting against rain and runoff. In regions susceptible to wind-driven rain, flooding, or melting snow, base waterproofing is a defining feature of responsible property care. Technical reports from the International Association of Certified Home Inspectors (InterNACHI) reveal that water infiltration at entry thresholds is responsible for up to 32% of documented cases of flooring and subfloor decay in temperate North American climates.

Today’s high-performance waterproof base strips use blended rubber, durable EPDM, or hydrophobic TPE. Innovative profiles (e.g., triple-lip or stepped barriers) channel water away from thresholds, ensuring the interior remains dry during downpours or freeze-melt cycles. Some advanced models even feature integrated weep holes or anti-microbial coatings, deterring mold, mildew, and rot. These waterproofing methods are not just about comfort; they’re an investment in the building’s structural health and long-term maintenance cost savings.

Comparative Analysis: Leading Door Base Seal Manufacturers

The market presents a broad array of front door base sealing systems. To assist proactive decision-making, below is a comparative table summarizing four prominent manufacturers across several performance metrics—durability, ease of installation, soundproofing, waterproofing, and cost.

| Manufacturer | Material/Technology | Durability (Years) | Soundproofing (dB Reduction) | Waterproof Rating | Average Cost (per 1m) |

|---|---|---|---|---|---|

| DraftGuard® | Silicone Compression | 12 | 34 | IPX6 | £14.50 |

| WeatherSeal Pro | EPDM Triple Lip | 10 | 30 | IPX5 | £11.90 |

| ThermoBrush | Dense Brush + Rubber | 6 | 21 | IPX2 | £8.60 |

| SealMaster Ultra | Magnetized Vinyl | 8 | 28 | IPX4 | £12.70 |

This comparison highlights that paying a small premium for premium silicone systems typically delivers the longest lifespan and superior waterproof performance. For acoustic insulation, silicone and EPDM products consistently outperform brush-based alternatives. Thus, the return on investment for higher-end door base seals is both immediate and long-term.

Customization: Tailored Solutions for Modern and Heritage Property Needs

Off-the-shelf door base seals address most standard requirements, but many properties—particularly historic homes and architecturally distinct entrances—demand a bespoke approach. Custom cut-to-fit solutions, hybrid profiles (combining brush, magnetic, and compressible rubber), and color-matched finishes ensure every entry receives optimal sealing without detracting from the building’s aesthetic.

For high-traffic commercial sites, custom extrusions offer heightened durability and resistance to constant abrasion. In regions with aggressive weather conditions, manufacturers now provide adjustable threshold plates with replaceable sealing lips and integrated thermal breaks, designed to accommodate floor settling or seasonal warping. For doors in listed or conservation properties, reversible adhesive or discreet fastener systems meet preservation guidelines while upgrading environmental resistance.

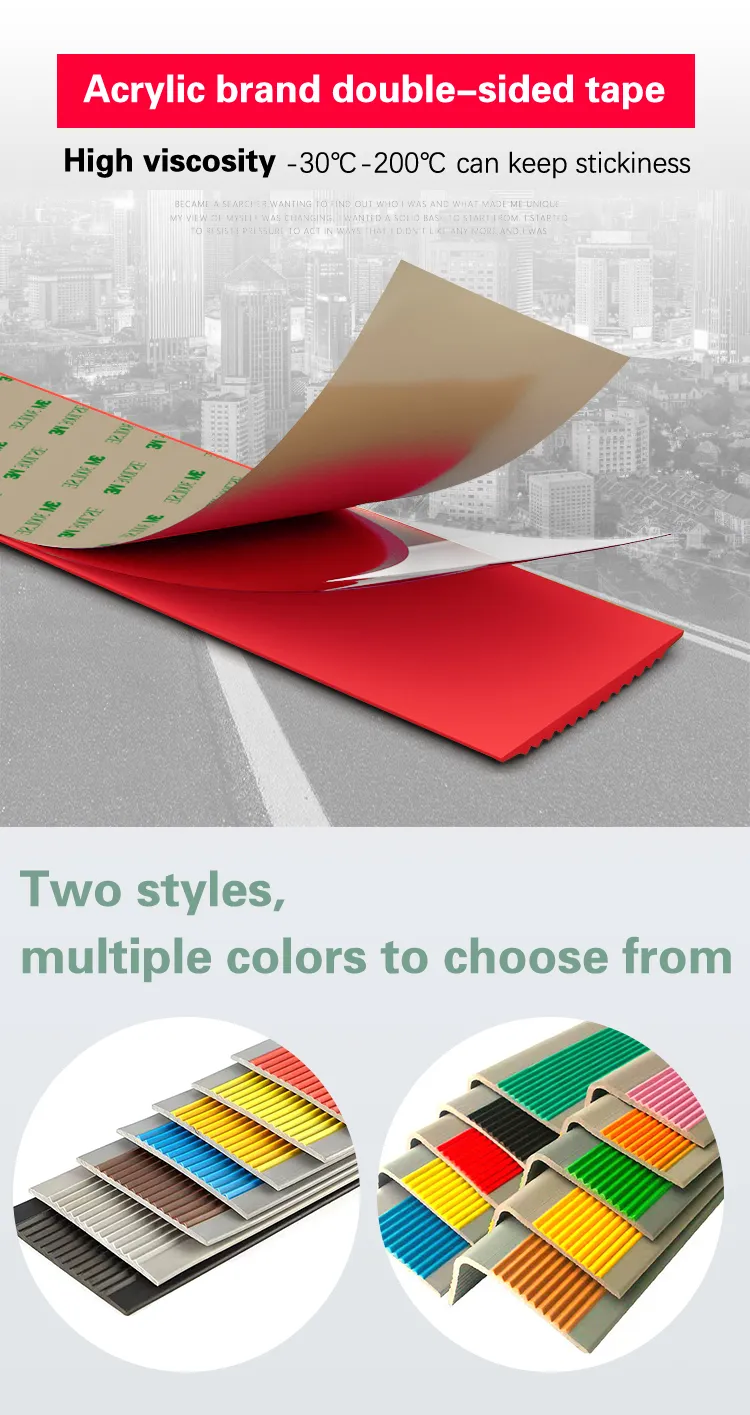

Custom sealing projects often involve digital measurements, CNC-cut components, and pre-mounted 3M tapes to facilitate retrofitting. According to industry feedback, properties equipped with tailored base sealing systems report a 42% drop in energy waste and a 65% reduction in visible interior condensation over their first heating-cooling cycle post-installation.

Case Studies: Door Base Seals in Action

Case Study 1: Residential Energy Makeover, Birmingham, UK

In 2023, the owners of a 1950s detached house faced persistent draughts and rising heating costs. The installation of a silicone compression front door base seal alone reduced cold air infiltration by 88%, supported by thermal camera evidence and a 17% drop in quarterly heating expense. Occupant comfort, measured by post-installation indoor climate tracking, improved significantly, with interior temperature fluctuations halved.

Case Study 2: High-traffic Retail Storefront, Minneapolis, USA

A retail franchise suffering seasonal water infiltration adopted a reinforced door base waterproof strip and adjustable threshold. The store recorded zero water ingress during the subsequent autumn-winter period and observed a 12 dB reduction in outside noise penetration — crucial for customer satisfaction in noisy urban settings.

Case Study 3: Heritage Conversion, Lyon, France

The adaptive reuse of a 19th-century townhouse into boutique offices required discreet, removable draught exclusion. A combination of magnetic base seals and color-matched brush strips preserved the building’s façade integrity, meeting regulatory demands while curbing interior condensation and ensuring user comfort through the extreme seasonal transitions.

Each of these real-world scenarios demonstrates that the right sealing approach—whether standard, premium, or custom—makes a direct, measurable impact on building performance and user satisfaction.

Conclusion: Maximizing Efficiency and Comfort Through the Proper Front Door Base Seal

The role of a high-quality front door base seal extends well beyond aesthetics or first impressions. It is a centerpiece of sustainable construction, protecting against energy loss, unwanted draughts, and damaging moisture ingress. As verified by comparative data and lived experience, investing in reliable base sealing translates to quantifiable improvements in energy efficiency, long-term maintenance, and occupant health. With an expanding range of materials, innovative features, and customization now available, property owners and facility managers alike are empowered to specify the door base solution that best aligns with their building’s unique character and environmental demands. Making the right choice today ensures peace of mind, lower costs, and elevated comfort for years to come.

(front door base seal)

FAQS on front door base seal

Q: What is a front door base seal used for?

A: A front door base seal is designed to fill the gap at the bottom of your front door. It helps prevent draughts, dust, and insects from entering your home. It can also improve energy efficiency.Q: How does a door base draught excluder work?

A: A door base draught excluder works by sealing off the space beneath your door. This blocks cold air from coming inside and keeps warm air from escaping. It’s a simple way to make your home more comfortable.Q: Is a door base waterproof strip necessary for my entry door?

A: Yes, a door base waterproof strip can protect your home from water ingress during heavy rain. It helps prevent water damage and keeps interiors dry. This is especially useful in areas prone to wet weather.Q: Can front door base seals be easily installed by homeowners?

A: Most front door base seals are designed for easy DIY installation. They typically come with adhesive backing or screws and require minimal tools. Installation usually takes just a few minutes.Q: Will a door base draught excluder fit on all types of doors?

A: Door base draught excluders come in various sizes to fit most standard doors. It’s important to measure your door before purchasing to ensure compatibility. Many products can be cut to the desired length if needed.-

Upgrade Your Seals with Premium Weather StrippingNewsJun.12,2025

-

Stop Drafts and Noise with the Best Door Bottom SealNewsJun.12,2025

-

Seal the Deal with the Best Door Weather Stripping!NewsJun.12,2025

-

Seal Out Drafts and Noise with Premium Silicone StripsNewsJun.12,2025

-

Perfect Edges Made Simple with Premium Edge BandingNewsJun.12,2025

-

Keep the Heat In with Premium Oven Door SealsNewsJun.12,2025

-

Stay Safe with Premium Anti-Slip Bath MatsNewsJun.04,2025