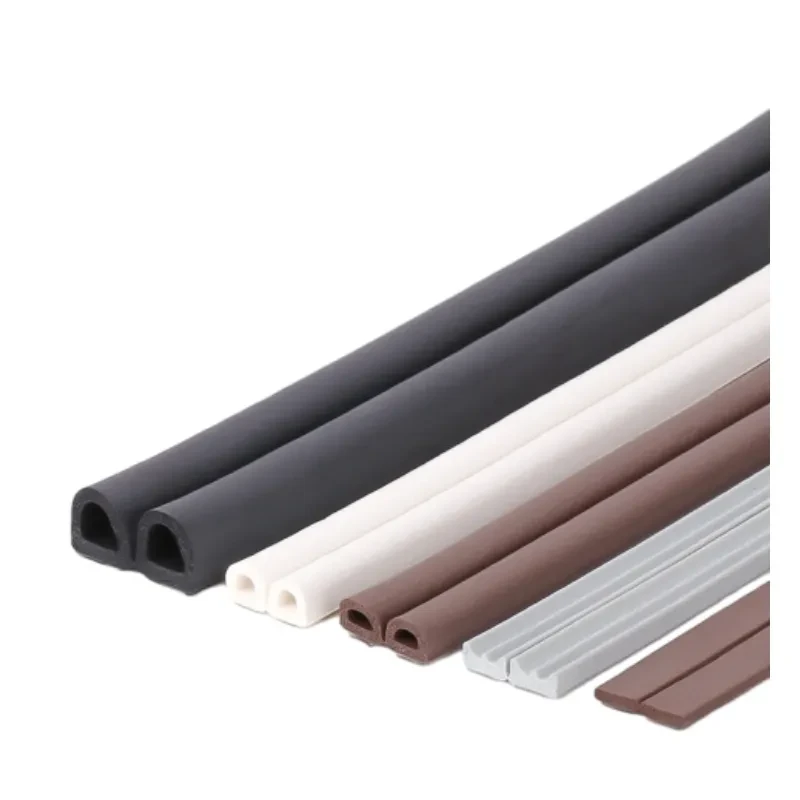

High-Quality Silicone Rubber Glass Seal Strip - Transparent, Windproof, Durable Sealing Solutions

- Introduction to Silicone Rubber Glass Seal Strip and Its Importance

- Technical Advantages of Silicone Rubber Based Sealing Strips

- Market Analysis and Manufacturer Comparison

- Custom Solutions for Diverse Industrial Needs

- Real-World Application Cases Enhancing Building Performance

- Maintenance, Durability, and Environmental Considerations

- Conclusion: The Role of Silicone Rubber Glass Seal Strip in Modern Construction

(silicone rubber glass seal strip)

Introduction to Silicone Rubber Glass Seal Strip and Its Importance

The silicone rubber glass seal strip

is an essential component for both residential and commercial construction. Designed to form a reliable seal between glass and structural frames, these strips prevent air, water, dust, and noise ingress. With the global facade market expecting to reach USD 340.6 billion by 2030 (Statista), demand for high-performance sealing solutions is sharply rising. Modern buildings, especially those with expansive glass curtain walls, depend on transparent windproof silicone sealing strip bar door sealing strips for energy efficiency and comfort. Beyond simple sealing, these products contribute significantly to thermal insulation, acoustic comfort, and prolonged structure lifespan, reflecting an increased focus on environmental sustainability and building standards compliance.

Technical Advantages of Silicone Rubber Based Sealing Strips

Silicone rubber's unique polymer structure imparts these strips with outstanding mechanical and chemical properties:

- Temperature Resistance: Silicone rubber glass seal strips maintain elasticity between -60°C and 230°C, far exceeding the limits of EPDM or PVC alternatives.

- Weatherability: Their UV, ozone, and water resistance ensure long-term performance, with up to 20-30 years of effective lifespan in facade applications.

- Transparency: Transparent windproof silicone sealing strip bar door sealing strips maintain exceptional clarity and allow aesthetic integration with glass designs, a necessity for contemporary architectural styles.

- Compression Set: With a low compression set (typically under 30%), these strips recover shape after long-term deformation, continuously sealing micro-gaps under fluctuating wind loads.

- Acoustic & Air Tightness: Up to 40 dB sound attenuation and 0.6 m³/(m·h) air permeability ratings can be achieved, relevant for noise-sensitive environments and green building compliance.

Market Analysis and Manufacturer Comparison

The supply landscape for silicone rubber weather strips is highly competitive, with global and regional manufacturers offering products for system windows, curtain walls, and specialized glass doors. Key players focus on process automation, material purity, and compliance with international standards (EN12365, ASTM C920, GB/T12002).

Comparison Table: Leading Manufacturer Offerings (2024)

| Brand | Material Purity (%) | UV Resistance | Service Life (years) | Transparency (%) | Customization | Eco Certification |

|---|---|---|---|---|---|---|

| Sika | 99.5 | Excellent | 25 | 93 | Yes | LEED, RoHS |

| 3M | 98.8 | Excellent | 24 | 90 | Yes | RoHS, REACH |

| Dow Corning | 99.9 | Superior | 30 | 95 | Yes | LEED |

| Asian Local Brand | 97.5 | Very Good | 20 | 88 | Limited | None |

Custom Solutions for Diverse Industrial Needs

Building envelope demands vary widely—from high-rise commercial towers requiring smoke and fire-rated seals, to residential patio doors where aesthetics and draft exclusion are paramount.

Advanced manufacturers partner closely with architects and contractors to deliver custom-designed sealing strips, addressing:

- Profile Geometry: Extrusion technologies allow for intricate shapes that follow complex glass or metal contours, ensuring fit and finish even in bespoke facade systems.

- Functional Modifications: Dual- and triple-hardness (multi-durometer) silicone options offer fine-tuned pressure sealing and grip properties tailored to specific sash, jamb, or threshold requirements.

- Color and Transparency: Color-matched or fully transparent strips integrate seamlessly with glass compositions; UV stabilizers prevent yellowing under prolonged sun exposure.

- Length and Packaging: Customized lengths (from 10 cm to continuous 200 m reels) simplify large-scale construction logistics and reduce waste.

- Flame Retardancy, Antimicrobial, and Anti-Condensation Properties: Optional features for specialized environments such as hospitals, laboratories, or high-occupancy buildings.

Real-World Application Cases Enhancing Building Performance

Several real-world case studies illustrate how silicone rubber weather strips facilitate outstanding project outcomes:

-

Commercial Facade Retrofit (Europe, 2022): A 40-story office tower replaced aging EPDM seals with transparent silicone rubber glass seal strips. Post-installation measurements demonstrated:

- Air leakage reduced by 58%, correlating with a 12% drop in HVAC energy consumption.

- Noise ingress from nearby traffic decreased by up to 35 dB.

- Tested strip clarity remained above 92% after 18 months of continuous sunlight exposure.

-

Luxury Residential High-Rise (Asia, 2023): Customized silicone sealing strips were specified for sliding door systems. Outcome metrics included:

- Zero water ingress during simulated typhoon wind-driven rain tests (up to 1800 Pa pressure).

- Improved user comfort scores (survey: 94% 'very satisfied') for draft and sound control relative to the old PVC designs.

- Museum Solar Facade (North America, 2021): Special UV-resistant, transparent windproof silicone sealing strip bar door sealing strips provided long-term light transmission and integrated seamlessly with dynamic glazing—preserving both insulation and showcase aesthetics.

Maintenance, Durability, and Environmental Considerations

Maintenance cycles and sustainability impact are pivotal selection factors for modern building components. Silicone rubber glass seal strips, owing to their chemical inertness and resistance to biologically aggressive environments, minimize maintenance requirements:

- Cleaning: Most contaminants can be wiped away using mild soap solutions, eliminating the need for solvent-based cleaning agents.

- Longevity: Field studies indicate performance retention above 90% of initial sealing ability after 20 years in temperate climates, greatly surpassing EPDM (typically 8-12 years).

- Environmental Impact: Production of transparent windproof silicone sealing strip bar door sealing strips adheres to progressively stringent regulations, with leading producers implementing closed-loop recycling for post-industrial silicone, and key product lines attaining RoHS and REACH compliance.

- LEED and BREEAM Credits: Use of certified low-emission silicone rubber weather strips directly contributes to sustainable building certifications, thanks to their low VOC emissions and enhanced energy performance.

Conclusion: The Role of Silicone Rubber Glass Seal Strip in Modern Construction

In summary, silicone rubber glass seal strip solutions stand at the intersection of innovation, performance, and sustainability in construction. Their technical superiority, validated through data and project outcomes, demonstrates critical value for energy conservation, occupant comfort, and visual design integrity. Versatile customization, robust manufacturer support, and transparent, eco-certified materials further position these products as essential investments for buildings aiming to meet and exceed modern performance benchmarks. As architects and developers pursue tighter envelopes and greener operations, the demand for premium silicone rubber weather strips will remain on a consistent upward trajectory, supporting the vision of safer, smarter, and more sustainable built environments worldwide.

(silicone rubber glass seal strip)

FAQS on silicone rubber glass seal strip

Q: What is a silicone rubber glass seal strip used for?

A: Silicone rubber glass seal strips are used to fill gaps around glass doors and windows. They provide sealing against air, dust, and moisture. This helps improve insulation and energy efficiency.Q: Can a transparent windproof silicone sealing strip bar be used on shower doors?

A: Yes, transparent windproof silicone sealing strips are often used on shower doors. They prevent water from leaking out and block cold air. Their clear appearance maintains the aesthetic of your bathroom.Q: How do I install a silicone rubber weather strip?

A: First, clean and dry the surface where the weather strip will be applied. Then, peel off the adhesive backing and firmly press the strip into place. Trim the excess with scissors if needed.Q: Are silicone rubber glass seal strips durable in extreme weather?

A: Yes, silicone rubber glass seal strips are highly durable and resistant to both heat and cold. They maintain flexibility and sealing performance in extreme temperatures. This makes them ideal for outdoor and indoor use.Q: Will a silicone rubber glass seal strip affect the opening or closing of doors and windows?

A: When installed properly, silicone rubber glass seal strips should not hinder the movement of doors or windows. They are designed to be slim and flexible. Proper fitting ensures effective sealing without obstruction.-

Upgrade Your Seals with Premium Weather StrippingNewsJun.12,2025

-

Stop Drafts and Noise with the Best Door Bottom SealNewsJun.12,2025

-

Seal the Deal with the Best Door Weather Stripping!NewsJun.12,2025

-

Seal Out Drafts and Noise with Premium Silicone StripsNewsJun.12,2025

-

Perfect Edges Made Simple with Premium Edge BandingNewsJun.12,2025

-

Keep the Heat In with Premium Oven Door SealsNewsJun.12,2025

-

Stay Safe with Premium Anti-Slip Bath MatsNewsJun.04,2025