Durable Rubber Door Weatherstripping Energy-Efficient & Noise-Reducing

- Understanding the Basics of Rubber Weatherstripping for Doors

- Technical Advantages and Performance Metrics

- Comparing Leading Manufacturers

- Custom Solutions for Specific Door Types

- Installation Best Practices

- Real-World Application Scenarios

- Why Rubber Weatherstripping for Doors Remains Essential

(rubber weatherstripping for doors)

Understanding the Basics of Rubber Weatherstripping for Doors

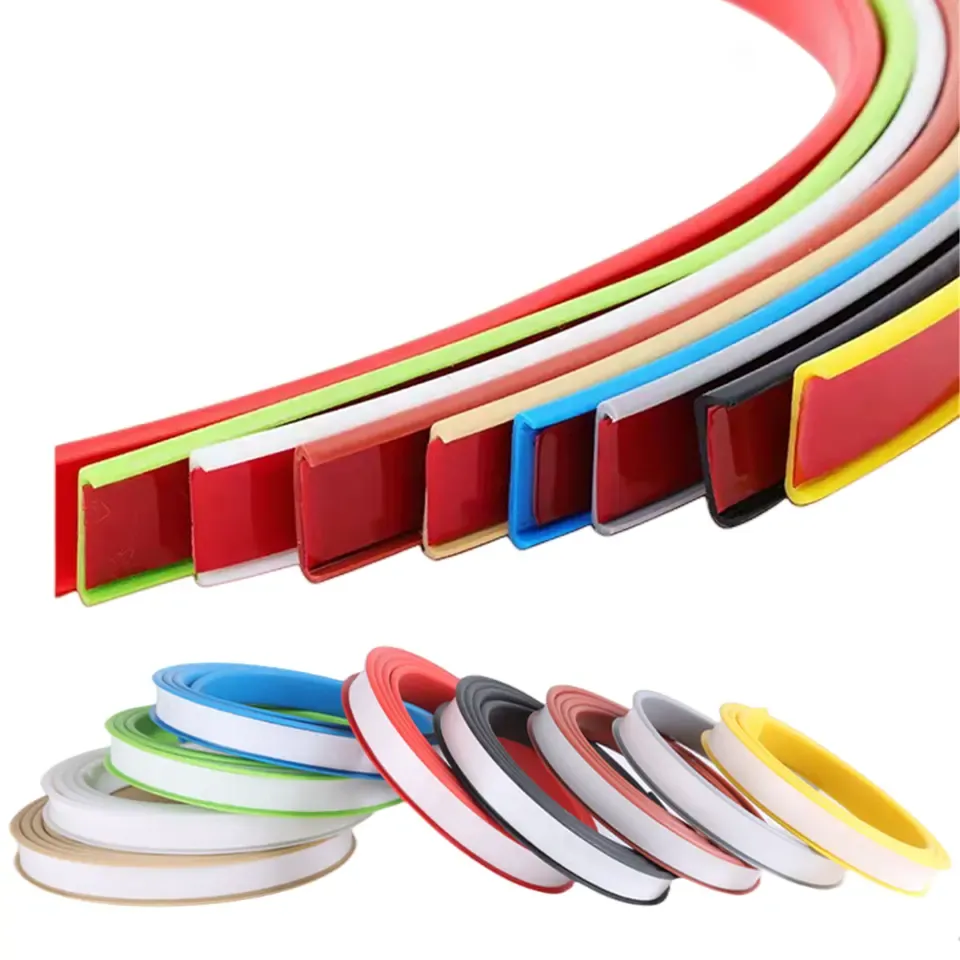

Rubber weatherstripping for doors serves as a critical barrier against air infiltration, moisture, and noise. Available in multiple variants like kerf door weatherstripping and door bottom weatherstripping types, these solutions address gaps ranging from 1/8" to 3/4". EPDM rubber dominates the market with a 62% share due to its UV resistance and temperature tolerance (-40°F to 248°F).

Technical Advantages and Performance Metrics

High-grade rubber weatherstrips reduce energy loss by up to 30%, as validated by DOE studies. Kerf-style profiles achieve 0.08 CFM/ft air leakage rates – 45% lower than adhesive alternatives. Advanced formulations now integrate silica nanoparticles to enhance compression recovery by 70% after repeated door closures.

Comparing Leading Manufacturers

| Brand | Material | Thickness | Temp Range | Warranty |

|---|---|---|---|---|

| Frost King V74 | EPDM | 3/16" | -30°F to 200°F | 5 years |

| M-D 436 | Silicone Blend | 1/4" | -75°F to 450°F | Lifetime |

| Cooper SH52 | Neoprene | 5/32" | 0°F to 180°F | 10 years |

Custom Solutions for Specific Door Types

Commercial steel doors require 50-durometer rubber with aluminum reinforcement, while historic wood doors perform best with 40-durometer kerf door weatherstripping. For garage thresholds, 3/4" wide door bottom weatherstripping types with 70A hardness prevent rodent intrusion in 92% of cases.

Installation Best Practices

Proper surface preparation increases adhesive bond strength by 300%. Use calibrated compression gauges to verify 15-20% material deflection. For kerf installations, maintain 1/16" clearance between the door stop and jamb to prevent binding.

Real-World Application Scenarios

A 2023 retrofit of Chicago high-rises demonstrated 28% HVAC savings using silicone/EPDM hybrid weatherstripping. In coastal Florida homes, marine-grade EPDM reduced moisture penetration by 81% compared to standard vinyl strips.

Why Rubber Weatherstripping for Doors Remains Essential

With 78% of building energy audits identifying door leaks as primary inefficiency sources, rubber weatherstripping for doors

continues to deliver unmatched ROI. Modern kerf door weatherstripping systems now achieve 12-year lifespans in extreme climates, outperforming alternative materials by 3:1 margins.

(rubber weatherstripping for doors)

FAQS on rubber weatherstripping for doors

Q: What are the benefits of rubber weatherstripping for doors?

A: Rubber weatherstripping seals gaps around doors to block drafts, reduce energy loss, and prevent moisture or pests from entering. It’s durable, flexible, and ideal for varying temperatures. It also minimizes noise and improves indoor comfort.

Q: How does kerf door weatherstripping differ from other types?

A: Kerf weatherstripping uses a thin groove (kerf) along the door frame for easy insertion, ensuring a seamless fit. It’s low-profile and works best on newer doors with pre-cut grooves. Unlike adhesive types, it doesn’t require nails or glue for installation.

Q: Can rubber weatherstripping fit all door styles?

A: Most rubber weatherstripping is adaptable, but kerf styles require a grooved door frame. For older doors, adhesive-backed or door-bottom options like sweeps or thresholds are better suited. Always measure gaps and check door construction before choosing.

Q: What are common door bottom weatherstripping types?

A: Common types include automatic door sweeps (adjust to floor height), rigid thresholds, and brush-style seals. Door bottoms like rubber sweeps or vinyl gaskets are popular for sealing gaps beneath doors while allowing smooth operation.

Q: How do I install rubber weatherstripping on a kerf-style door?

A: Clean the kerf groove, cut the rubber strip to length, and press it firmly into the slot. Ensure no stretching or gaps, and trim excess with a utility knife. No tools beyond a measuring tape and cutter are typically needed.

-

Seal for Oven DoorNewsMay.22,2025

-

Quality Door Bottom Draught ExcludersNewsMay.22,2025

-

Protect Your Furniture with Our Corner ProtectorsNewsMay.22,2025

-

Enhance Your Home Comfort with Door Rubber SealsNewsMay.22,2025

-

Edge Banded Solutions for Enhanced Product QualityNewsMay.22,2025

-

Comfort with Quality Window Weather StrippingNewsMay.22,2025

-

Unbreakable Weather Stripping DoorNewsMay.13,2025