When to Replace Your Sealing Rubber Strip for Optimal Performance

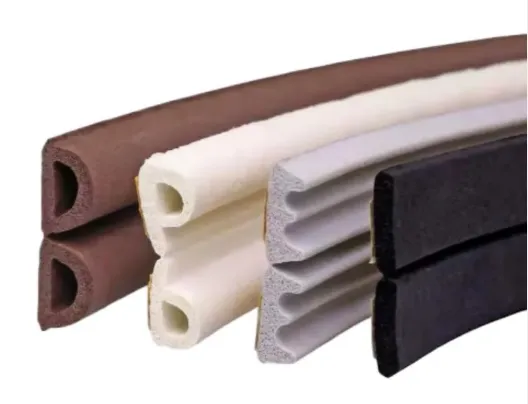

Sealing Rubber Strips play a crucial role in maintaining indoor comfort by providing an airtight and watertight seal for doors, windows, and shower enclosures. Over time, however, these strips may wear out, compromising their sealing effectiveness. Knowing when to replace your Sealing Rubber Strip is essential to maintaining energy efficiency, noise reduction, and overall comfort.

When You Need to Replace the Sealing Rubber Strip

One of the most common signs that it’s time to replace your Sealing Rubber Strip is visible wear and tear. Cracks, splits, or brittleness indicate that the rubber has lost its elasticity, affecting its sealing performance. Exposure to extreme temperatures, UV radiation, and humidity can accelerate this deterioration, especially in areas like windows and shower doors rubber seals.

Another sign to look for is reduced insulation. If you notice drafts, increased noise levels, or water leaks, it’s likely that the Sealing Rubber Strip is no longer effective. This can result in higher energy bills, as the compromised seal allows air to escape, reducing the efficiency of heating and cooling systems.

Deformation or flattening of the Sealing Rubber Strip is also an indicator of wear. When the rubber loses its original shape due to constant compression or stretching, it can no longer provide a tight seal. This is particularly common in rubber gasket seal for door applications, where frequent opening and closing put pressure on the strip.

Age is another factor to consider. Even if there are no visible signs of damage, it’s recommended to replace Sealing Rubber Strips every few years to ensure optimal performance. Over time, the rubber’s elasticity and sealing capabilities naturally degrade, making replacement a proactive measure to maintain efficiency.

Regular inspection and maintenance are essential for detecting these issues early. By checking your Sealing Rubber Strips periodically, you can identify signs of wear and replace them before they compromise your home’s comfort and energy efficiency.

Common Problems You May Encounter When Using Sealing Rubber Strips

Despite their durability and effectiveness, Sealing Rubber Strips may encounter common problems that affect their performance. One of the most frequent issues is adhesive failure. If the adhesive backing loses its grip, the strip may peel off, leading to gaps and reduced sealing efficiency. This is especially problematic in indoor door weather stripping, where constant movement can weaken the adhesive bond.

Another common issue is shrinkage. Over time, some rubber materials may contract, leading to gaps and reduced insulation. This is typically caused by exposure to extreme temperatures or prolonged UV exposure. Selecting high-quality Sealing Rubber Strips made from temperature-resistant and UV-stable materials can minimize this problem.

Deformation and compression set are also common issues. When Sealing Rubber Strips are subjected to continuous pressure or uneven compression, they lose their shape and elasticity, leading to gaps and reduced sealing performance. This is particularly relevant for rubber gasket seal for door applications, where frequent opening and closing cause the rubber to flatten over time.

Water leakage is another issue, especially in shower doors rubber seals. If the strip is not installed properly or becomes deformed, water can seep through, leading to mold growth and water damage. Ensuring a tight and even installation is crucial to prevent this problem.

Noise penetration and drafts are other common complaints. When Sealing Rubber Strips lose their shape or elasticity, they fail to block out noise and air effectively. This affects indoor comfort and increases energy consumption. Regular maintenance and timely replacement are essential to maintaining optimal performance.

To avoid these issues, it is important to select high-quality Sealing Rubber Strips suitable for the specific application. Proper installation, regular maintenance, and timely replacement also play a crucial role in ensuring long-term performance and durability.

Installation Methods of Various Sealing Rubber Strips

The effectiveness of Sealing Rubber Strips largely depends on proper installation. Different types of Sealing Rubber Strips require different installation methods to ensure a tight and secure fit. Here’s how to install the most common types:

For self-adhesive Sealing Rubber Strips, installation is relatively straightforward. Start by cleaning the surface thoroughly to remove dust, dirt, and grease. This ensures maximum adhesion and durability. Measure and cut the strip to the desired length, peel off the adhesive backing, and press the strip firmly into place. Make sure to apply even pressure along the entire length for a secure bond. This method is commonly used for indoor door weather stripping and rubber gasket seal for door applications.

For non-adhesive Sealing Rubber Strips, installation involves using mounting brackets, clips, or adhesives. This method provides a more durable and long-lasting seal, especially for heavy-duty applications. Begin by measuring and cutting the strip to fit the desired area. Secure the strip using mounting clips or brackets, ensuring a snug and even fit. This method is ideal for shower doors rubber seals, where water resistance and durability are essential.

In applications where a custom fit is required, such as irregularly shaped doors or windows, a combination of adhesive and mechanical fasteners can be used. This provides extra security and prevents the strip from shifting or peeling off over time.

It is important to avoid stretching or compressing the Sealing Rubber Strip during installation, as this can lead to deformation and reduced sealing effectiveness. Additionally, applying the strip at room temperature ensures optimal flexibility and adhesion.

For shower doors rubber seals, using a waterproof adhesive enhances water resistance and prevents mold growth. In high-traffic areas such as rubber gasket seal for door applications, using heavy-duty adhesive ensures long-term durability and performance.

Proper installation not only enhances the sealing effectiveness of Sealing Rubber Strips but also prolongs their lifespan and reduces maintenance needs. By following the correct installation methods, you can ensure optimal performance and energy efficiency for years to come.

Why Sealing Rubber Strips Are the Best Choice for Your Home

Sealing Rubber Strips offer superior performance, durability, and energy efficiency compared to other sealing solutions. Their flexibility and resilience make them ideal for doors, windows, and shower enclosures, providing a reliable and long-lasting seal. Unlike foam or felt seals, Sealing Rubber Strips maintain their shape and elasticity, ensuring consistent sealing performance over time.

Whether used as indoor door weather stripping or shower doors rubber seals, these strips effectively block drafts, water leaks, and noise, enhancing indoor comfort and energy efficiency. Additionally, their resistance to UV radiation, extreme temperatures, and chemicals ensures long-term durability and minimal maintenance.

Sealing Rubber Strips are also easy to install, making them a cost-effective solution for homeowners and builders alike. Their versatility and wide range of applications make them the preferred choice for residential and commercial projects.

Investing in high-quality Sealing Rubber Strips guarantees improved insulation, noise reduction, and energy savings. With their competitive pricing and superior performance, they offer exceptional value and reliability. Choose Sealing Rubber Strips for a comfortable, energy-efficient, and quiet living environment.

-

Upgrade Your Seals with Premium Weather StrippingNotiziaJun.12,2025

-

Stop Drafts and Noise with the Best Door Bottom SealNotiziaJun.12,2025

-

Seal the Deal with the Best Door Weather Stripping!NotiziaJun.12,2025

-

Seal Out Drafts and Noise with Premium Silicone StripsNotiziaJun.12,2025

-

Perfect Edges Made Simple with Premium Edge BandingNotiziaJun.12,2025

-

Keep the Heat In with Premium Oven Door SealsNotiziaJun.12,2025

-

Stay Safe with Premium Anti-Slip Bath MatsNotiziaJun.04,2025