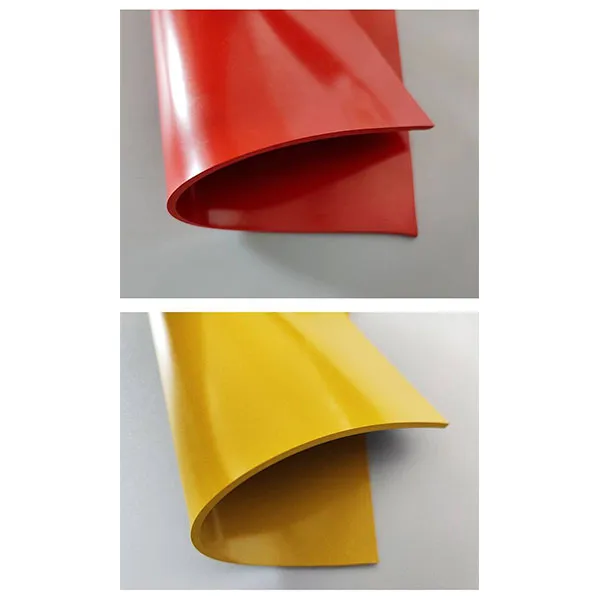

FKM Rubber Sheets | High Temp & Chemical Resistant

Over the past decade, the global fkm rubber sheet market has experienced a consistent compound annual growth rate (CAGR) of 5.2% (Source: MarketsandMarkets, 2023), driven by the increasing demand for high-performance sealing solutions in the petrochemical, food processing, automotive, and heavy machinery sectors. As industrial processes advance, both fkm rubber sheet and silicone strip seal technologies are evolving to meet more rigorous chemical resistance, durability, and environmental safety requirements.

- Petrochemical & Oil Field—Focusing on corrosion & high-temp resistance; FKM & EPDM outperform traditional rubbers.

- Water Treatment & Pipeline—Reliability and anti-aging for gasket/strip applications.

- Metallurgy & Energy—Silicone strip seals offer flexibility in smart grid sensors & transmission systems.

| Parameter | FKM Rubber Sheet | Silicone Strip Seal |

|---|---|---|

| Material base | Fluoroelastomer (FKM, e.g., Viton®) | High purity silicone rubber |

| Temperature Resistance | -25°C to +250°C | -60°C to +200°C |

| Chemical Resistance | Excellent (acids, fuels, hydrocarbons) | Very Good (water, mild chemicals, ozone) |

| Hardness (Shore A) | 60-85 | 35-80 |

| Compression Set (%) | 8-15 | 10-30 |

| Maximum Tensile Strength (MPa) | 10-17 | 7-10 |

| Flame Resistance | Very Good | Excellent |

| Certifications Available | ISO 9001:2015, FDA, ASTM D1418 | ISO 9001:2015, FDA, RoHS |

- Compounding: Blending FKM polymer (Fluoroelastomer), fillers, plasticizers, curing agents—ensures uniform dispersion for consistent performance.

- Sheet Forming: Calendering for standard sheets; compression/transfer molding for precision tolerance. Modern CNC finishing ensures perfect geometries.

- Vulcanization: Cross-linking under 170–180°C (ISO 3302-1 compliant), for maximum elastomer resilience.

- Inspection/Testing: Rigorous mechanical, chemical, and visual checks (per ISO 2781, ASTM D2000); includes tensile strength, acid soak, and life cycle tests.

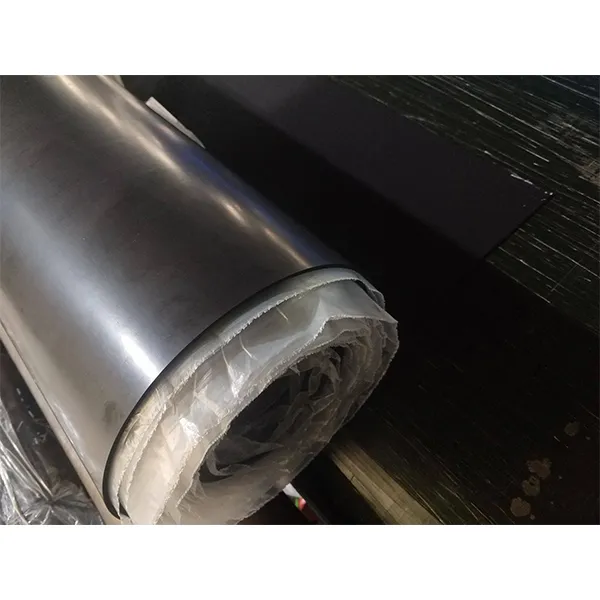

Manufacturing Technology: Key methods: Calendering for uniform thickness (±0.07mm tolerance); CNC cutting for custom gaskets or strip seals well suited for automation-driven workflows.

Testing Standards: ISO 9001:2015, ASTM D2000, FDA for food/pharma, ANSI/SAE J200 for automotive, and ASTM D1418 (elastomer identification).

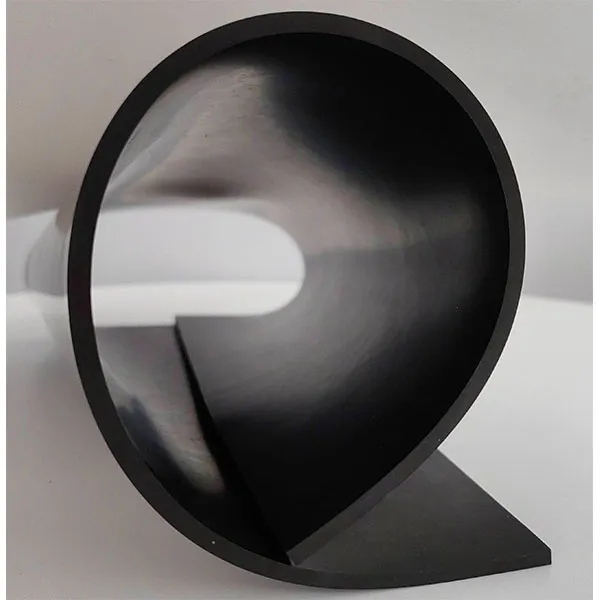

The Factory Sale Industrial Black Shock Absorbing EPDM stands out as a high-performance elastomer solution for environments where robust shock absorption, weather resistance, and durability are critical. EPDM (Ethylene Propylene Diene Monomer) is renowned for its resistance to UV, ozone, acids, and temperature extremes.

- Material: Industrial grade, high-density EPDM (black, peroxide-cured)

- Temperature Range: -40°C to +130°C (intermittent peaks of +160°C)

- Hardness: Shore A 65±5

- Tensile Strength: ≥ 9.0 MPa

- Elongation at break: ≥ 350%

- Compression Set (70°C, 22h): ≤ 20%

- Finish: Smooth/sanded, customizable thickness (2mm–50mm)

- Certifications: ISO 9001:2015, REACH, RoHS

(FKM vs. EPDM vs. Silicone)

- Superior Chemical Resistance: Unaffected by most oils, fuels, acids, aromatic/aliphatic hydrocarbons—far exceeds EPDM and general silicone (measured per ASTM D471 swelling index).

- High-Temperature Endurance: Continuous operation up to 250°C with minimal change in mechanical properties. Essential for refinery, turbine, and heat exchanger seals.

- Outstanding Longevity: Lifecycle testing demonstrates a 2x–3x longer lifespan than comparable elastomer sheets, with fewer maintenance shutdowns.

- Compliance and Safety: FDA (21 CFR 177.2600) and RoHS certified grades available for food, pharma, and potable water use.

| Brand / Parameter | Factory Sale (QZseals) | Generic China | Major EU Brand |

|---|---|---|---|

| Material Grade | Premium EPDM (ISO 9001, Peroxide Cured) | Standard EPDM (Mixed Curing) | Premium EPDM (Peroxide Cured) |

| Thickness Range (mm) | 2–50 | 2–30 | 1–40 |

| Service Life Estimate (years, 90°C) | 9–12 | 6–8 | 8–13 |

| Certifications | ISO 9001, RoHS, REACH | ISO 9001 (Basic) | ISO 9001, EN 681-1, KTW |

| Custom Machining | Yes (CNC, Die Cut) | Limited | Yes |

| Sample Lead Time | 5 days | 10 days | 7 days |

| OEM Support | Full (Logo & Packaging) | No | Partial |

Custom fkm rubber sheet & Silicone Strip Seal Solutions:

Whether for extreme chemical environments (acid/alkali plants), precision machining applications, or high-volume automated production, our R&D and technical support teams can engineer bespoke rubber compounds—adjusting hardness, thickness, surface, and certification per client need.

- CNC Gasket Cutting: Tolerance down to ±0.05mm for critical flange/sealing interfaces.

- Food/Pharma: FDA & EC 1935/2004 compliant sheets; no leachable plasticizers.

- Energy/Metallurgy: Formulate for flame resistance and anti-static properties (per EN 13501-1, IEC 61340).

- HVAC/Water: Large volume strip-seal supply, custom die-length, and surface embossing for anti-slip installs.

- Petrochemical Plant Seals & Gaskets: FKM sheet used for tank flange sealing in refineries (resists >1000h exposure to H2S, per ASTM D471).

- Water Treatment Pipeline Gaskets: EPDM-based strip seals withstand continuous chlorine exposure in municipal plants.

- Railway Anti-Vibration Pads: Black Shock Absorbing EPDM sheets dampen vibration—service cycle >10 years, certified to EN 45545-2.

- Pharmaceutical Machinery: Silicone strip seal ensures non-toxic, FDA-compliant solution for peristaltic pipelines.

— Process Manager, Sinopec (2022 Field Data).

- Delivery: Standard: 7~12 days after order confirmation, expeditable for urgent engineering projects.

- Warranty: 18 months from delivery; covers manufacturing and material defects. On-site replacement and technical diagnosis available (Asia, EU, NA regions).

- Customer Support: Engineering consultations, installation guidance, and after-sales reports. Direct support via phone/email/live chat—Contact QZseals.

Both fkm rubber sheet and silicone strip seal technologies are critical for next-generation industrial performance. By leveraging advanced manufacturing, rigorous ISO/ASTM quality standards, and proven real-world case histories, QZseals assures unmatched reliability and cost-effectiveness for customers globally.

For further reading, see peer-reviewed discussions and technical insights at:

- Rubber World Magazine: Market & Technology Updates

- ScienceDirect: Polymers in Harsh Environments

- Sealing.net Professional Forums

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025