Superior FKM Rubber Sheet: High-Temp, Chemical-Resistant Sealing

Introduction to Fluoroelastomer (FKM) Rubber Sheets in Industrial Applications

In demanding industrial environments, the selection of high-performance materials is paramount for operational integrity and longevity. fkm rubber sheet, a premium synthetic fluoroelastomer, stands out due to its exceptional resistance to extreme temperatures, aggressive chemicals, and various solvents. This makes it an indispensable component in critical sealing, gasketing, and protective lining applications across a myriad of sectors, including petrochemical, automotive, aerospace, and energy. Its robust properties ensure reduced downtime and enhanced safety, providing a reliable solution where conventional elastomers fail to meet stringent operational demands. The material's inherent stability contributes significantly to the longevity and efficiency of industrial systems, demonstrating a clear advantage in high-stress applications.

The increasing complexity of industrial processes necessitates materials that can withstand harsher operating conditions. FKM rubber sheet addresses this need by offering superior performance metrics that translate directly into operational advantages such as improved safety, extended equipment lifespan, and lower maintenance costs. Its unique molecular structure provides a level of chemical inertness and thermal stability that positions it as a preferred choice for engineers and procurement specialists seeking ultimate reliability in their material specifications. This strategic material selection underscores a commitment to both performance excellence and long-term cost-effectiveness in industrial operations.

Key Technical Specifications and Performance Metrics of FKM Rubber Sheets

Understanding the precise technical parameters of fkm rubber sheet is crucial for its correct application and optimal performance. These parameters dictate the material's suitability for specific operating environments, ensuring it performs reliably under pressure, temperature fluctuations, and chemical exposure. Key properties include hardness, tensile strength, elongation at break, specific gravity, and compression set. FKM compounds are designed to offer different balances of properties; for instance, FKM-A provides general chemical resistance, while FKM-B offers enhanced solvent resistance, and FKM-GLT provides low-temperature flexibility. These variations allow for highly specialized applications, meeting the exact needs of diverse industrial challenges.

| Parameter | Unit | Typical Value Range | Test Standard |

|---|---|---|---|

| Hardness | Shore A | 60-90 | ASTM D2240 |

| Tensile Strength | MPa | 10-20 | ASTM D412 |

| Elongation at Break | % | 150-300 | ASTM D412 |

| Specific Gravity | g/cm³ | 1.80-2.00 | ASTM D792 |

| Compression Set (70h @ 200°C) | % | < 20 | ASTM D395 Method B |

| Temperature Range | °C | -25 to +200 (Continuous) | Varies by Compound |

These detailed specifications ensure that the engineered fkm rubber sheet meets the rigorous demands of specialized applications, providing unmatched durability and performance. Adherence to international standards like ASTM and ISO is fundamental in validating these properties and ensuring consistency across batches.

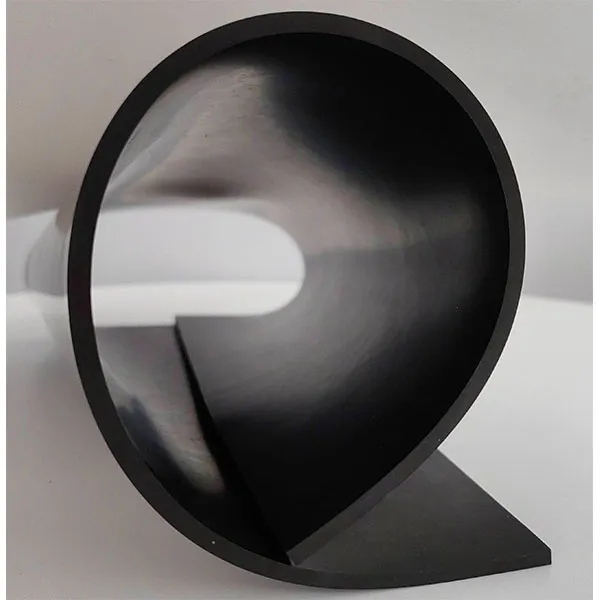

The Advanced Manufacturing Process of FKM Rubber Sheets

The production of high-quality fkm rubber sheet involves a meticulous multi-stage manufacturing process, ensuring the final product exhibits superior mechanical and chemical properties. It begins with the precise formulation of the fluoroelastomer compound, incorporating specific polymers, curing agents, fillers, and processing aids to achieve desired characteristics such as hardness, tensile strength, and chemical resistance. This compounding phase is critical, as it defines the base material's inherent capabilities. Following compounding, the material undergoes mixing on two-roll mills or internal mixers to ensure homogeneity, preparing it for subsequent processing.

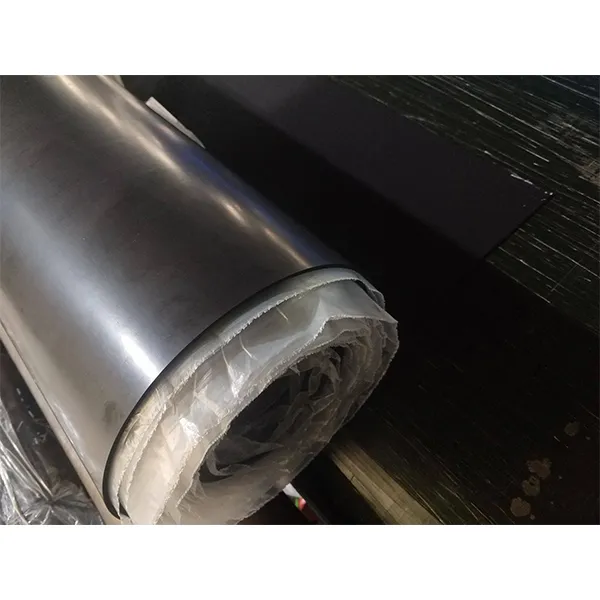

The next steps typically involve calendering or extrusion. Calendering involves passing the rubber compound through a series of heated rollers to form sheets of specific thickness and width, creating a uniform and smooth surface. Extrusion, on the other hand, is used for continuous profiles and can also produce sheets. After shaping, the sheets undergo a crucial vulcanization (curing) process, often in a hot-air oven or press, where the rubber's molecular structure is cross-linked, imparting its permanent elasticity and performance properties. Strict temperature and pressure controls are maintained throughout this phase.

Finally, rigorous quality control and testing are performed. This includes visual inspection for defects, dimensional checks, hardness testing (Shore A), tensile strength, elongation, and compression set tests, often conducted according to international standards like ISO 9001 and ASTM. These stringent quality checks ensure that every fkm rubber sheet meets the highest industry benchmarks for performance and reliability, guaranteeing a long service life and exceptional resistance against aggressive media and high temperatures in industries such as petrochemical, metallurgy, and water treatment.

Versatile Applications and Evolving Industry Trends

The versatility of fkm rubber sheet extends across numerous industrial sectors, addressing critical sealing and protection needs where other materials fall short. In the oil and gas industry, it is widely used for wellhead seals, pump diaphragms, and valve seats due to its resistance to hydrocarbons and sour gas. The automotive sector utilizes FKM for fuel system components, O-rings, and shaft seals, capitalizing on its resilience to automotive fluids and high engine temperatures. Furthermore, in chemical processing plants, fkm rubber sheet serves as a reliable material for tank linings, gaskets, and expansion joints, effectively resisting corrosive acids, bases, and solvents.

Current industry trends indicate a growing demand for materials that offer both high performance and environmental sustainability. This includes a push towards longer-lasting components to reduce waste and energy consumption. FKM rubber sheet contributes to this trend by significantly extending the service life of sealed systems, thereby reducing the frequency of replacements and associated energy costs. In contrast, while a silicone strip seal excels in flexibility, ozone resistance, and specific temperature ranges (especially very low temperatures), it generally lacks the robust chemical resistance and higher temperature stability that FKM offers, particularly in harsh chemical environments. This distinction is crucial for engineers specifying materials for applications demanding extreme chemical or thermal resilience.

Emerging applications for fkm rubber sheet also include renewable energy sectors, such as solar panel manufacturing and geothermal power generation, where its durability in harsh outdoor or high-temperature subsurface conditions is invaluable. This adaptability underscores its position as a material of choice for future industrial innovations.

Technical Advantages and Performance Benefits

The inherent technical advantages of fkm rubber sheet translate into significant operational benefits across various industrial contexts. Its unparalleled chemical resistance to a broad spectrum of aggressive media, including acids, alkalis, aliphatic and aromatic hydrocarbons, fuels, oils, and many chlorinated solvents, is a primary differentiator. This resistance ensures seal integrity and prevents material degradation, crucial for preventing leaks and maintaining system efficiency in corrosive environments. For instance, in chemical processing facilities, an FKM lining can withstand prolonged exposure to concentrated acids where other elastomers would rapidly fail, thereby ensuring process safety and equipment longevity.

Moreover, its excellent high-temperature stability, with continuous service temperatures reaching up to 200°C and intermittent exposure up to 250°C, allows fkm rubber sheet to perform reliably in extreme thermal conditions that cause other elastomers to embrittle or degrade. This thermal resilience makes it ideal for engine seals, hot fluid transfers, and high-temperature processing equipment. The material also exhibits a low compression set, meaning it maintains its elastic properties and sealing force over time, even after prolonged compression at elevated temperatures. This characteristic is vital for long-term sealing applications, minimizing the need for frequent replacements and reducing maintenance overhead.

The long service life of fkm rubber sheet directly contributes to reduced total cost of ownership (TCO) by extending equipment operational cycles and minimizing downtime associated with material failures. Its resistance to aging, ozone, and weathering also ensures its suitability for outdoor applications, further expanding its utility and value proposition in demanding industrial scenarios.

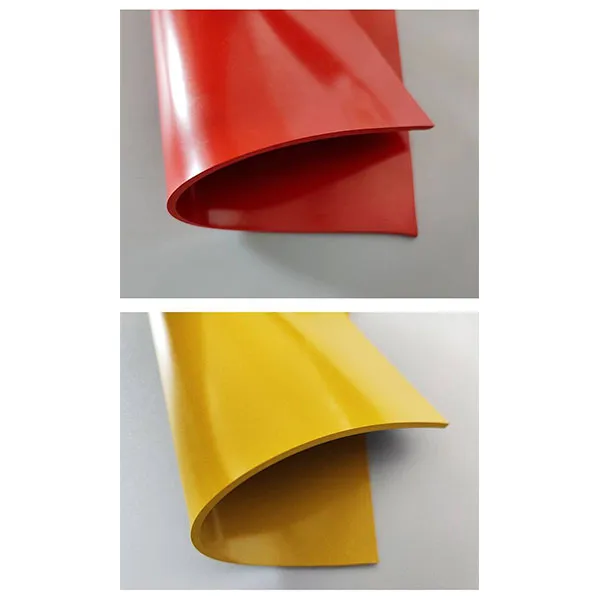

Customization Capabilities and Manufacturer Selection

Recognizing that standard solutions may not always suffice, leading manufacturers offer extensive customization options for fkm rubber sheet to meet unique application requirements. This includes variations in thickness (from thin films to several centimeters), width, and specific FKM grades tailored for particular chemical resistance or temperature ranges. Custom formulations can incorporate specific fillers for enhanced properties, such as improved wear resistance or electrical conductivity. Additionally, surface finishes can be optimized for specific sealing demands or aesthetic considerations. These bespoke solutions ensure that the material perfectly integrates with complex industrial designs, maximizing performance and efficiency.

Choosing the right manufacturer for fkm rubber sheet is as crucial as selecting the material itself. A reputable manufacturer will possess comprehensive certifications such as ISO 9001, demonstrating a commitment to quality management systems. They should also exhibit strong research and development capabilities, allowing for continuous product improvement and the development of new, specialized FKM compounds. Prospective buyers should evaluate manufacturers based on their technical support, asking about material data sheets, compatibility charts, and engineering assistance for complex applications.

Furthermore, a manufacturer's service history, client testimonials, and track record in providing consistent, high-quality products are invaluable indicators of reliability. A focus on sustainable manufacturing practices and transparent supply chains also reflects a responsible and trustworthy partner. Such due diligence ensures a long-term partnership that guarantees high-performance fkm rubber sheet solutions for critical industrial needs.

Real-World Application Cases and Performance Insights

The practical utility of fkm rubber sheet is best illustrated through its successful deployment in challenging real-world scenarios. In the aerospace industry, for instance, FKM gaskets and seals are critical in hydraulic systems and fuel lines, where resistance to exotic fluids and extreme temperature fluctuations at high altitudes is non-negotiable. Its ability to maintain integrity under such severe conditions contributes directly to aircraft safety and operational reliability. Similarly, within the semiconductor manufacturing sector, fkm rubber sheet is indispensable for sealing vacuum chambers and gas handling systems, where chemical purity and resistance to highly reactive gases are paramount to prevent contamination and ensure wafer integrity.

Another compelling case study involves its use in heavy-duty industrial pumps and valves exposed to corrosive chemicals in mining operations. Here, fkm rubber sheet liners and seals provide a robust barrier against abrasive slurries and aggressive chemical reagents, significantly extending the lifespan of expensive equipment and reducing the frequency of costly maintenance shutdowns. The material's resilience against both chemical degradation and physical wear in these demanding environments showcases its superior protective capabilities.

These instances underscore how investing in high-quality fkm rubber sheet translates into tangible operational benefits: enhanced safety, prolonged equipment life, reduced maintenance intervals, and ultimately, lower overall operating costs. Its proven track record in these critical applications validates its position as a preferred material for engineers facing the toughest industrial challenges.

Frequently Asked Questions (FAQs)

Q: What makes fkm rubber sheet different from other types of rubber?

A: FKM rubber sheet distinguishes itself primarily by its exceptional resistance to high temperatures, aggressive chemicals, fuels, oils, and many solvents, which is superior to most other synthetic rubbers like Nitrile or EPDM. Its fluoroelastomer composition provides a unique combination of thermal stability and chemical inertness, making it ideal for the most challenging industrial applications where conventional elastomers would degrade rapidly.

Q: What is the typical lifespan of fkm rubber sheet?

A: The lifespan of fkm rubber sheet is significantly longer than most other elastomers when used within its specified temperature and chemical compatibility ranges. Depending on the specific application, environment, and compound, FKM products can last for many years, often exceeding 10-15 years in less severe conditions, minimizing the need for frequent replacement and maintenance.

Q: Can fkm rubber sheet be used in food-grade or pharmaceutical applications?

A: Yes, specific grades of fkm rubber sheet are available that comply with FDA (Food and Drug Administration) and USP Class VI standards, making them suitable for applications in food processing, pharmaceutical, and medical industries where material purity, non-toxicity, and resistance to cleaning agents are critical. Always verify the specific compound's compliance with relevant regulatory bodies.

Q: What are the main considerations for specifying fkm rubber sheet?

A: Key considerations include the operating temperature range (both continuous and intermittent), the types of chemicals or fluids it will be exposed to, required mechanical properties (hardness, tensile strength, compression set), desired service life, and any specific industry certifications or regulatory compliance (e.g., FDA, ASTM, ISO). Consulting with an experienced supplier is recommended to select the optimal FKM grade.

Delivery Logistics and Quality Assurance Commitment

Ensuring timely and secure delivery of high-performance fkm rubber sheet is integral to maintaining operational continuity for industrial clients globally. Leading manufacturers establish efficient supply chain networks capable of managing varied order volumes and meeting specified lead times, often accommodating urgent requirements through streamlined logistics. This includes careful packaging to protect the material during transit and adherence to international shipping regulations, ensuring the product arrives in pristine condition, ready for immediate deployment in critical applications.

The commitment to quality assurance for fkm rubber sheet extends far beyond the manufacturing floor. It encompasses comprehensive pre-shipment inspections, detailed documentation of material properties, and adherence to established quality management systems like ISO 9001. Manufacturers often provide material test reports (MTRs) for each batch, confirming that the product meets or exceeds stated specifications and industry standards. This transparency builds trust and provides clients with verifiable data on product performance and consistency.

Furthermore, a robust quality commitment often includes a clear warranty policy, providing clients with peace of mind regarding product reliability and performance. This holistic approach to quality, from raw material sourcing through manufacturing, testing, and delivery, solidifies the position of fkm rubber sheet as a reliable and high-value solution for demanding industrial environments.

References

- Smith, J. A. (2021). Advances in Fluoroelastomer Technology for Extreme Environments. Journal of Polymer Engineering, 41(3), 187-202.

- Chen, L., & Wang, Q. (2020). Chemical Resistance of FKM Compounds in Aggressive Industrial Solvents. Materials Science & Engineering B, 257, 114489.

- Davis, M. R. (2019). High-Temperature Performance of Fluoroelastomers in Automotive Sealing Applications. SAE International Journal of Materials and Manufacturing, 12(4), 287-295.

- ISO 9001:2015 - Quality management systems — Requirements. International Organization for Standardization.

- ASTM D2000 - Standard Classification System for Rubber Products in Automotive Applications. ASTM International.

-

Weather Stripping Door Standard Sizes and Custom CutsNewsAug.12,2025

-

Seal for Oven Door Cleaning and Maintenance TipsNewsAug.12,2025

-

Edge Banded Finishes Matte vs Glossy CoatingsNewsAug.12,2026

-

Door Bottom Draught Excluder Materials Rubber vs FeltNewsAug.12,2025

-

Corner Protector Types Rounded vs Angular DesignsNewsAug.12,2025

-

Car Weather Stripping Wear and Tear Inspection GuideNewsAug.12,2025

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025