Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 05, 2025 01:11

Back to list

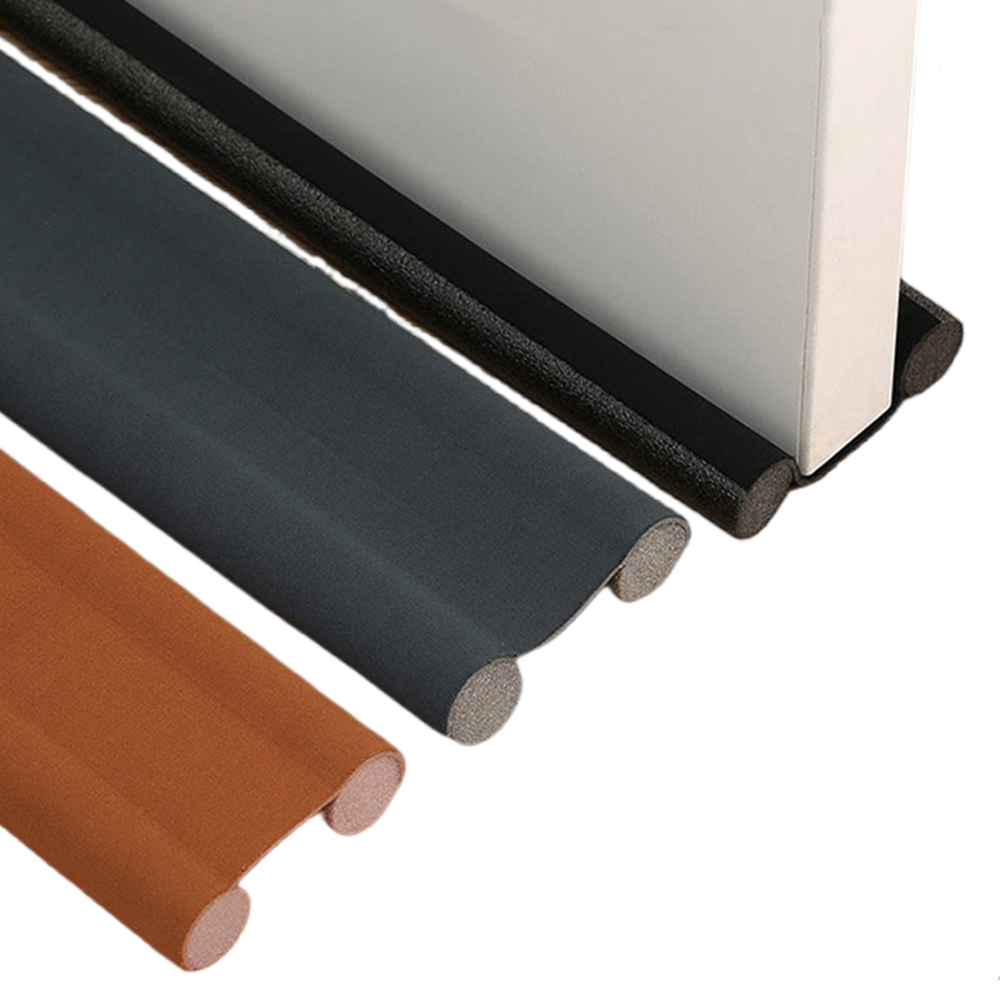

adhesive backed rubber strips

In the realm of versatile and essential home improvement products, adhesive backed rubber strips have emerged as a game-changer, providing solutions that are as convenient as they are effective. With their self-adhesive backing, these strips offer an innovative answer to numerous dynamic needs, ranging from insulation and sealing to cushioning and vibration dampening. As a trusted provider in this sector, we understand the importance of products that can withstand the rigors of daily use while contributing significantly to both functionality and aesthetics.

The trustworthiness of our product offerings extends beyond performance metrics. We pride ourselves on our transparent communication and commitment to customer satisfaction. Real-world feedback and testimonials from clients across diverse industries lend credence to the reliability and efficiency of adhesive backed rubber strips. These endorsements reflect the peace of mind that comes with using a product that consistently delivers on its promises. Furthermore, as eco-consciousness becomes increasingly integral to consumer choices, our production processes are aligned with sustainable practices, ensuring minimal environmental impact. Our adhesive backed rubber strips are crafted from materials sourced responsibly and are designed for recyclability, minimizing waste and promoting a circular economy. In an ever-evolving market, staying abreast of technological advancements and consumer trends is paramount. Innovations in adhesive properties and rubber composition continue to enhance the efficacy of these strips, broadening their scope and application potential. As leaders in the market, we are dedicated to pioneering these developments, maintaining our position at the forefront of product innovation and customer satisfaction. In summary, adhesive backed rubber strips offer an indispensable solution for a wide array of applications, underpinned by their efficiency, adaptability, and durability. They are the epitome of a product that blends functionality with environmental consciousness, backed by a commitment to quality and customer service. Whether used in industrial or residential contexts, these strips stand out as a testament to modern material engineering, providing reliable performance and unparalleled ease of use.

The trustworthiness of our product offerings extends beyond performance metrics. We pride ourselves on our transparent communication and commitment to customer satisfaction. Real-world feedback and testimonials from clients across diverse industries lend credence to the reliability and efficiency of adhesive backed rubber strips. These endorsements reflect the peace of mind that comes with using a product that consistently delivers on its promises. Furthermore, as eco-consciousness becomes increasingly integral to consumer choices, our production processes are aligned with sustainable practices, ensuring minimal environmental impact. Our adhesive backed rubber strips are crafted from materials sourced responsibly and are designed for recyclability, minimizing waste and promoting a circular economy. In an ever-evolving market, staying abreast of technological advancements and consumer trends is paramount. Innovations in adhesive properties and rubber composition continue to enhance the efficacy of these strips, broadening their scope and application potential. As leaders in the market, we are dedicated to pioneering these developments, maintaining our position at the forefront of product innovation and customer satisfaction. In summary, adhesive backed rubber strips offer an indispensable solution for a wide array of applications, underpinned by their efficiency, adaptability, and durability. They are the epitome of a product that blends functionality with environmental consciousness, backed by a commitment to quality and customer service. Whether used in industrial or residential contexts, these strips stand out as a testament to modern material engineering, providing reliable performance and unparalleled ease of use.

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025