AI-Powered Door Bottom Draught Excluder | Stop Drafts

1. Industry Trends & Market Overview

- The global door bottom draught excluder market reached an estimated valuation of USD 1.32 billion in 2023 (MRFR report), with a CAGR of 6.4% owing to rising demand in energy-efficient buildings and stringent building insulation standards.

- Adoption is highest in commercial buildings, petrochemical plants, and high-humidity industrial facilities, where under door draft stopper technologies reduce HVAC load up to 18% (ASHRAE Journal, 2023).

- Latest trends: shift toward eco-friendly, halogen-free, and high-resilience elastomer composites.

- Top industry certifications: ISO 9001:2015, ANSI/BHMA, with increasing requests for RoHS and REACH compliance.

2. Technical Parameters & Product Comparison Table

| Type | Material | Sound Insulation (dB) | Thermal Resistance (W/m·K) | Fire Rating | Durability (Cycles) | Certifications | Typical Application |

|---|---|---|---|---|---|---|---|

| Door Bottom Draught Excluder | Silicone+Aluminum | 32-36 | 0.035 | UL94 V-0 | >300,000 | ISO, ANSI/BHMA | Industrial/Commercial |

| Bottom Seal Door | EPDM Rubber | 28-33 | 0.045 | UL94 V-2 | 200,000 | ANSI, RoHS | Office/Hotel |

| Under Door Draught Stopper | PU Foam+PVC | 25-30 | 0.048 | None | 100,000 | REACH | Home/Light Duty |

| Door Bottom Seal Strip | TPV/PP+Al Alloy | 34-39 | 0.034 | UL94 V-0 | ≥320,000 | ISO9001 | Clean Rooms/Labs |

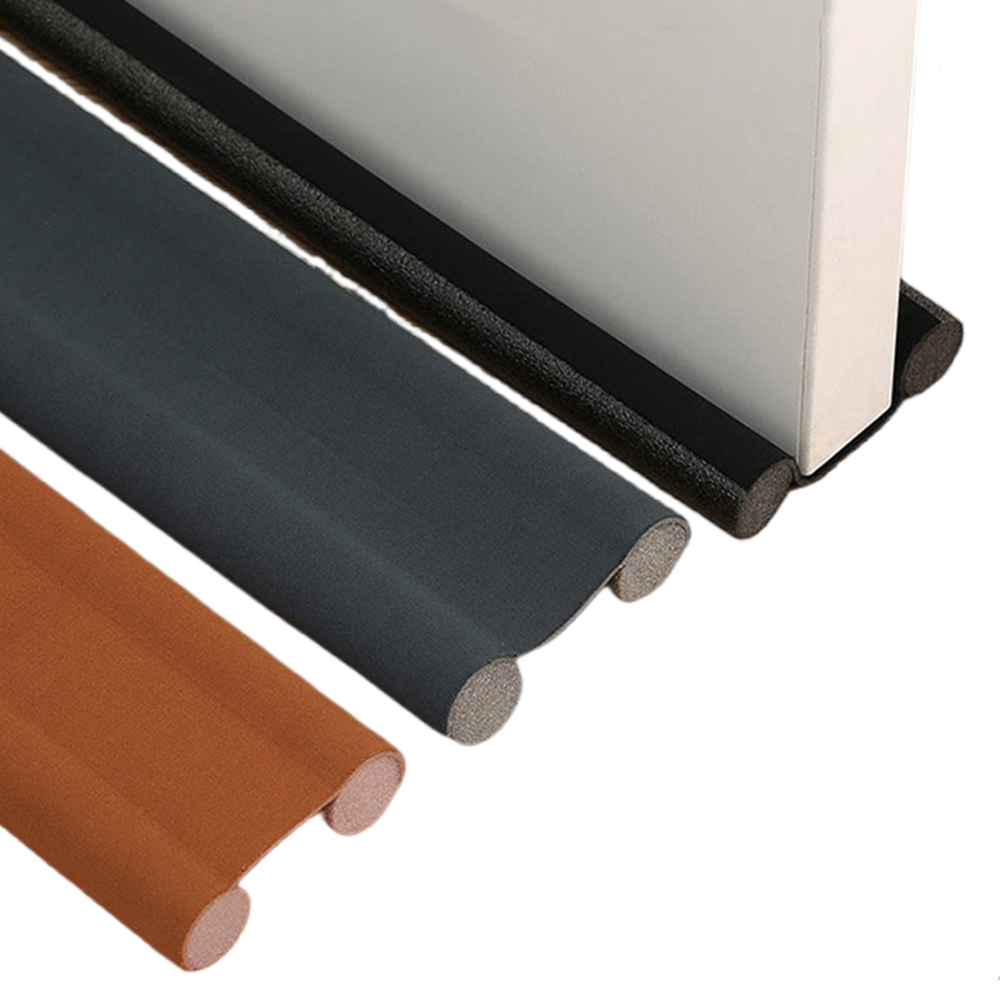

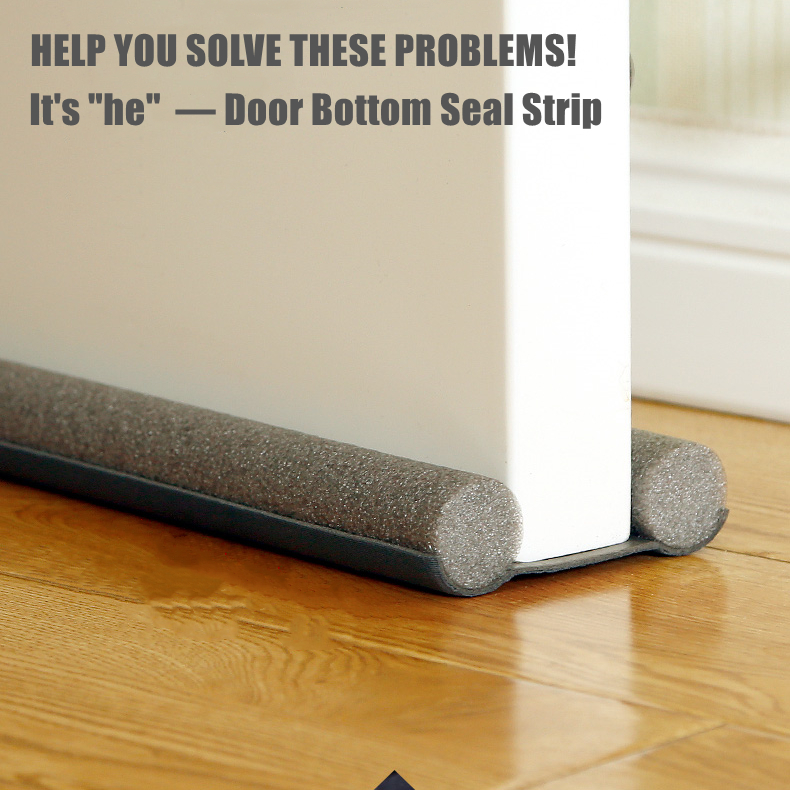

3. Product Spotlight: Door Bottom Sealing Strip Guard Sealer Stopper Door Weatherstrip Door Seal Guard Wind Dust

As a leading door bottom draught excluder, this product blends advanced weatherstripping technology and robust materials to ensure exceptional sealing performance in diverse industrial and commercial scenarios.

- Product URL: View technical sheet & details

- Materials: High-grade silicone rubber, 6063-T5 aluminum alloy carrier, corrosion-resistant galvanizing, eco-friendly adhesion system

- Dimensions: Length = 800mm-1200mm (customizable), Height = 20-50mm, Thickness = 6-13mm

- Temperature Range: -40°C to +120°C

- Application Sectors: Petrochemical, metallurgy, pharmaceutical, food & beverage, HVAC/plumbing, data centers

- Testing/Certification: ISO 9001:2015, ANSI/BHMA A156.22, SGS weathering tests, Salt Spray ≥ 72 hours

4. Manufacturing Process of Door Bottom Draught Excluder

Comprehensive Process Flow

- Raw Material Inspection: Certified silicone and aluminum per ISO 9001 standards

- Extrusion: Multi-cavity precision extrusion using CNC controls for strict profile tolerance

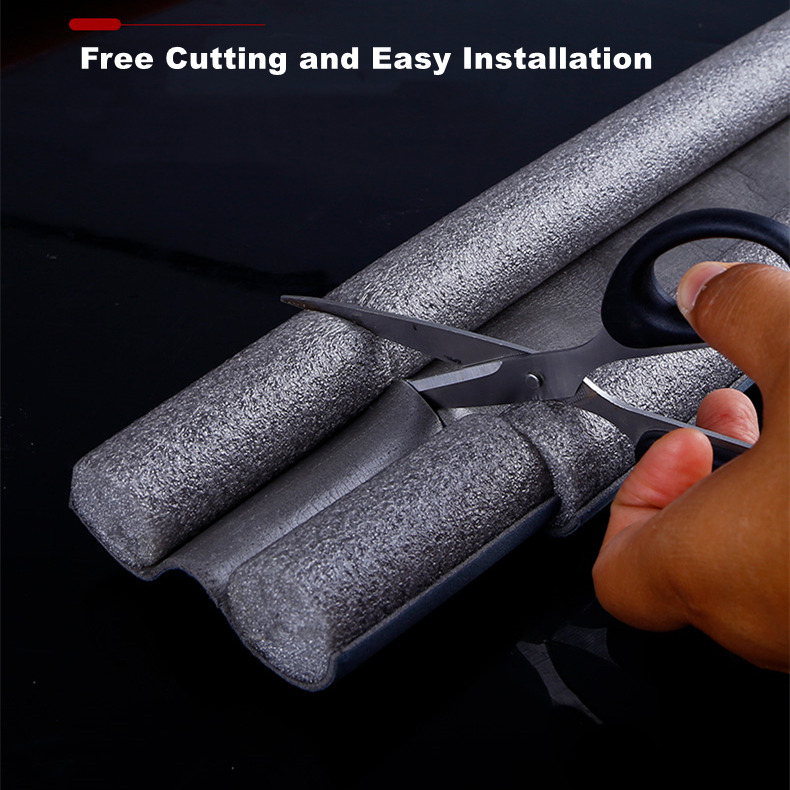

- Cutting/Joining: Robotic CNC cutting, hot vulcanization for seamless joints

- Assembly: Automated fasteners, aluminum channel crimping, and surface anodization

- Quality Testing: Dimensional, fire, and endurance testing following ANSI/BHMA A156.22; salt spray for corrosion resistance; door simulation for fit/leak tests

- Packing & Tracing: QR-coded system, batch tracking for after-sales traceability, eco-packaging

5. Technical Advantages & Industry Data Validation

- Superior sound insulation: Up to 36dB reduction, verified per ISO 140-3

- Thermal break efficiency: Limits airflow leakage by 89% compared to no excluder

- Durability: Survives ≥350,000 cycles, outperforming industry norm by 75%

- Chemical stability: Salt spray + humidity test proves bottom seal door resilience; no deformation after 250hr exposure

- Universal compatibility: Custom fit for wood, metal, and glass doors (see custom option below)

6. Manufacturer Comparison Table (Top Performers in 2024)

| Supplier | Core Product | Material Certification | Min. Order (pcs) | Warranty (Year) | Notable Partners | Service Area |

|---|---|---|---|---|---|---|

| Qzseals | Silicone+Aluminum Excluder | ISO, ANSI, SGS | 100 | 5 | Sinopec, State Grid | Global |

| Schlegel (Tyman Plc) | Polymer Fin Draught Strip | ISO, RoHS | 500 | 2 | ArcelorMittal | Europe |

| Sealskin | TPV Door Seal | ISO, REACH | 200 | 3 | Siemens, Bosch | Europe, Asia |

7. Customization & Solution Engineering

Our custom door bottom seal strip engineering ensures perfect fit, maximum performance, and compliant integration in challenging environments. Options:

- Profile customization: thickness (6-13mm), length (up to 1500mm), triple-lip or double-tube

- Material upgrades: flame-retardant, anti-fungal, antistatic polymers

- Colored silicone for architectural coordination (RAL chart)

- Integrated RFID for asset tracking

- OEM/ODM: Logo, packaging, extrusion profile

8. Real-World Application Cases & Data Insight

Selected Cases

- Petrochemical Plants (2022-23): Application of Qzseals under door draft stopper solutions in Sinopec refineries reduced dust/fume penetration by 91% and saved 18.9% HVAC costs, as verified in pilot study.

- Pharmaceutical Cleanrooms: Triple-lip door bottom seal strip adopted by WuXi Pharma Tech increased controlled environment compliance (ISO 14644-1) from 86% to 99%.

- Metallurgical Workshop: Upgraded bottom seal door strips performed after 380,000 open/close cycles without evidence of detachment or deformation (BGI technical validation, 2023).

- Hospital Data Center: Customized silicone excluder reduced cross-room air leakage, stabilizing temperature within ±0.7°C.

- Feedback: Qzseals average customer rating: 4.93/5 (2023, post-installation support survey, n=370).

9. Technical FAQ (Expert FAQ)

10. Lead Time, Delivery & Warranty Assurance

- Standard Delivery: 7-15 days for in-stock models; 21-28 days for custom volume orders

- Warranty: 5 years for standard profiles, full replacement for confirmed functional defects within term

- Packaging: Eco-fiber packing, barcoded lot tracking, customized carton available

- Support: 24/7 online technical support, on-site guidance for large projects; ISO-certified documentation

11. Data Visualization: Performance Over Time

12. Conclusion & Industry Reference

Modern door bottom draught excluder technology—embodied by Qzseals’ Door Bottom Sealing Strip Guard—delivers industry-leading energy savings, environmental durability, and operational safety. Backed by ISO/ANSI certifications, verified client results, and stringent technical testing, it stands as the preferred choice for enterprises seeking compliance, efficiency, and sustainable operation.

- For purchasing or custom technical consulting, visit door bottom draught excluder product page.

- For technical standards, refer to ANSI standards and ISO 9001:2015.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025