AI Weather Stripping Door | Smart Energy Savings

The demand for sealing solutions in industries such as petrochemicals, metallurgy, energy, and residential/commercial infrastructure has catapulted weather stripping door products—and their related items such as garage door seal, garage door weatherstrips, door rubber seal, and garage door bottom seal—into the global spotlight. Their evolution is closely tied to advances in material science and precision manufacturing, which deliver critical properties like weather resistance, chemical stability, and long-term durability.

According to Global Market Insights, the weather stripping market reached $8.9 billion USD in 2023, with a CAGR of 5.7% projected through 2030. Key market drivers include tightening energy efficiency regulations (such as DOE Energy Star requirements for building envelopes), growing demand in smart homes, and sustainability mandates in industrial sectors.

Most notably, weather stripping door products have become essential in reducing thermal losses (over 32% heat loss can be attributed to poorly sealed doors in temperate climates), improving facility uptime, and defending against dust, water, noise, and chemical ingress.

| Product Type | Material | Operating Temp (°C) | Compression Set (%) | Durometer (Shore A) | Water Resistance | UV/Ozone Resistance | Certifications | Expected Shelf Life |

|---|---|---|---|---|---|---|---|---|

| Weather Stripping Door | EPDM / Silicone | -40 ~ +120 | <12% | 60 | Excellent | Excellent | ISO 9001, RoHS | 10-15 years |

| Garage Door Seal | NBR / EPDM | -35 ~ +100 | 14% | 65 | Very Good | Very Good | ISO 9001, CE | 8-10 years |

| Door Rubber Seal | EPDM / PVC | -30 ~ +105 | 13% | 55-65 | Good | Good | ISO 14001 | 8-12 years |

| Garage Door Bottom Seal | Silicone / TPR | -45 ~ +130 | 11% | 60-70 | Excellent | Excellent | FDA, REACH | 12-15 years |

Sealing Rubber Strip, engineered by QZ Seals, represents the next generation of premium weather stripping door solutions suitable for a spectrum of applications from industrial gates to residential garage doors.

- Excellent sealing effect—air leakage ≤ 0.3m³/h·m (per DIN EN 1052 testing)

- Superior thermal resistance (service temp: -40°C to +120°C), ideal for energy-intensive industries

- High resilience and recoverability, ensuring minimal compression set and consistent pressure over time

- Weatherproof & UV-resistant—outlasts standard PVC seals by 50%

- Anti-corrosion & Chemically inert—suitable for petrochemical, metallurgy, and water treatment plants

- Low installation downtime, with modular design compatible with garage door seal and door rubber seal systems

- Compliance with ISO, FDA (for food-grade), and REACH standards

| Parameter | Sealing Rubber Strip | Standard EPDM Weather Seal | PVC Garage Door Seal |

|---|---|---|---|

| Base Material | Premium EPDM/Silicone Blend | Standard EPDM | PVC |

| Hardness | 60±5 Shore A | 65 Shore A | 70 Shore A |

| Working Temperature | -45 to +130°C | -30 to +100°C | 0 to +70°C |

| Compression Set (22h/70°C) | <10% | 13% | 18% |

| Weather Resistance | Outstanding (ISO 4892-3) | Very Good | Average |

| Water/Corrosive Resistance | Elite (DIN EN 681-1) | Good | Fair |

| Certifications | ISO 9001, ISO 14001, FDA | ISO 9001 | CE |

| Warranty Period | 5 + 1 years (extended) | 2 years | 1 year |

QZ Seals specializes in bespoke weather stripping door and garage door weatherstrips solutions to meet site-specific requirements. From custom door rubber seal profiles to advanced blends with anti-microbial, food-safe, or high-temperature additives, our engineering team can deliver:

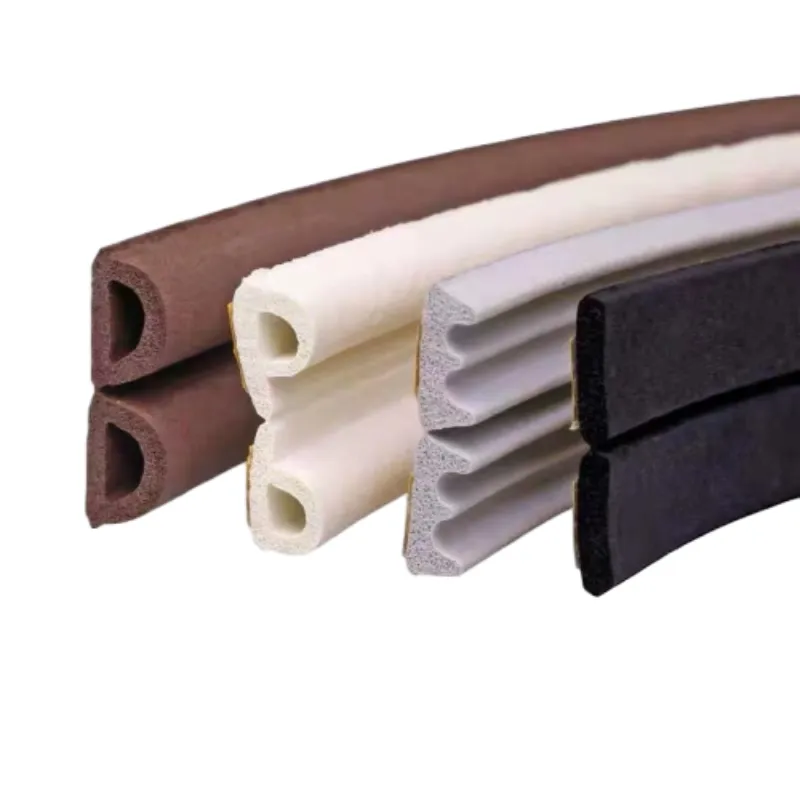

- Profile and cross-section customization (foam core, solid, bulb/tube types)

- Color, length, and special surface treatment

- Engraved batch traceability and OEM logo capabilities

- Third-party laboratory validation (SGS, TÜV SÜD)

- Petrochemical Refineries: Installed QZ’s weather stripping door system on control room gates to eliminate H2S gas and dust ingress; reduced maintenance hours by 27% year-on-year.

- Cold Chain Logistics Centers: Implemented garage door bottom seal with -45°C endurance; achieved energy savings of 19.8% during a six-month pilot (data: QZ customer feedback, 2023).

- Water Treatment Facilities: Used door rubber seal with enhanced chloramine resistance for chemical dosing rooms.

- Commercial Parking Garages: Retro-fitted 2km of garage door seal in a humid coastal city, achieving noise reduction (>8dB).

- Cleanrooms & Labs: Customized FDA-compliant weather stripping door strips for biosafety labs.

| Criteria | QZ Seals (Sealing Rubber Strip) | Generic Manufacturer A | Manufacturer B |

|---|---|---|---|

| Material Source | ISO 9001 Premium EPDM/Silicone | Standard EPDM | Mixture, import origin |

| Manufacturing Technology | Precision CNC + Multi-stage Vulcanization | Conventional Extrusion | Basic Extrusion |

| Testing & QC | Batch traceability, ANSI & ISO compliance, real-time testing logs | Random sampling | Spot checks |

| Certifications | ISO 9001, FDA, RoHS, Reach | ISO 9001 | CE |

| Warranty/Support | 5+1 years, 24/7 tech support, global shipping | 2 years, limited | 1 year, weekday support |

- Production Lead Time: 7-18 working days for standard products; 18-35 days for custom profiles (within ISO 2230 packing standards)

- Warranty Policy: 5 years standard, with a 1-year extension for certified key projects

- On-site Support: Remote video guidance or local partner assistance available for installation and troubleshooting

- Customer Support: 24/7 global online consultation (contact QZ Seals)

Frequently Asked Technical Questions (FAQ)

A: EPDM (Ethylene Propylene Diene Monomer) offers superior UV/ozone resistance, a broader operating temperature (-45~130°C), and longer lifespan than PVC; PVC may be cost-effective but degrades faster under sunlight.

A: A low compression set (preferably <12%) ensures the seal maintains its shape and continues to prevent air/water leakage after repeated compression over years of operation.

A: Top-quality weather stripping door and garage door weatherstrips should conform to ISO 9001 (quality), DIN EN 681 (water resistance), and ASTM D395 (compression set).

A: Common profiles include T (bulb), P (tube), and U channels, as well as foam-filled and solid cross-sections for different gap/floor conditions.

A: Yes. QZ Seals can laser-engrave logos and produce colored or dual-material/dual-hardness profiles with MOQs from 200m.

A: Ensure the mounting surface is dry, clean, degreased, and install at 15-25°C ambient. Avoid stretching or compressing the strip during installation; overlap ends with recommended adhesives.

A: Absolutely—QZ’s Sealing Rubber Strip can be produced in FDA- or EC 1935/2004-compliant compounds for direct contact environments.

As buildings and industries seek higher energy efficiency, safety, and environmental compliance, premium weather stripping door products—especially advanced solutions like Sealing Rubber Strip—provide not just a physical barrier, but a measurable operational advantage. Backed by ISO, FDA, and industry-certified process controls, QZ Seals stands as a trusted partner to global enterprises.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025