anti mat slip

Understanding Anti-Mat Slip Technology

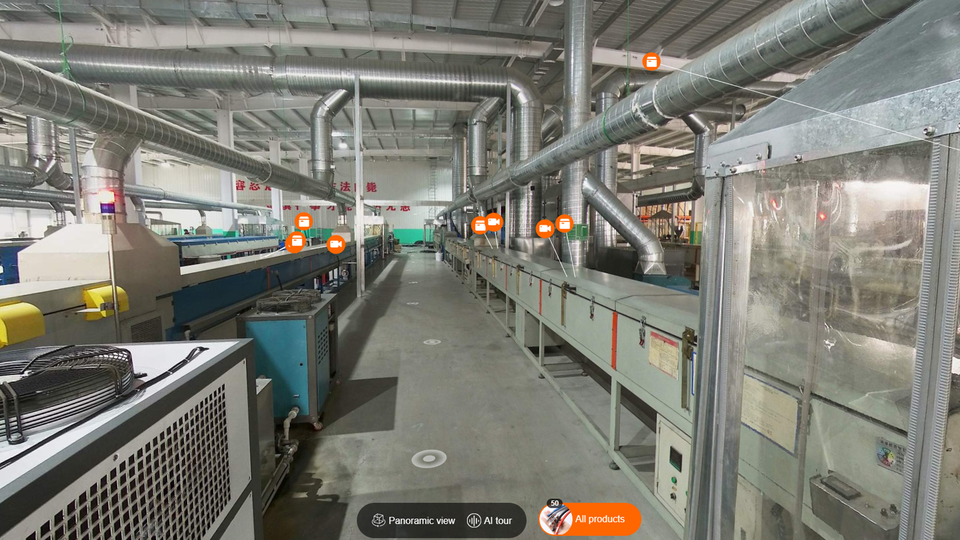

In the world of material science and manufacturing, the pursuit of enhancing the performance of composite materials has led to the development of innovative technologies, one of which is anti-mat slip technology. This advancement primarily addresses the challenges related to the slip characteristics of various materials, particularly in applications where friction and wear reduction are critical.

Understanding Anti-Mat Slip Technology

The fundamental principle behind anti-mat slip technology involves the introduction of specific additives or surface treatments that create a low-friction surface. These modifications can be achieved through various methods, including polymer blending, coatings, or the integration of nanoparticle additives that enhance lubrication properties. The result is a material that not only resists wear and tear but also maintains its operational integrity over extended periods.

anti mat slip

One of the key benefits of anti-mat slip technology is its ability to reduce maintenance costs. By minimizing the friction between moving parts, equipment operates more smoothly and efficiently, prolonging its lifespan and reducing the frequency of repairs and replacements. Additionally, this technology contributes to energy efficiency, as machines require less power to overcome friction, leading to lower energy consumption and reduced operational costs.

Furthermore, anti-mat slip materials can enhance the overall safety of products. In high-performance applications, the risk of failure due to excessive friction can lead to catastrophic results. By utilizing materials that incorporate anti-mat slip technology, manufacturers can mitigate these risks, providing more reliable and safer products to consumers.

In conclusion, anti-mat slip technology represents a significant advancement in material science, addressing crucial challenges in performance and efficiency. As industries continue to evolve and demand higher standards for performance, the integration of such technologies will play an essential role in shaping the future of manufacturing and product design. With ongoing research and development, the potential applications of anti-mat slip technology are vast, promising enhanced durability, reduced costs, and increased safety across various sectors.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025