Anti Slip Stair Strips: Durable Metal & Rubber Edge Protectors

The Critical Role of Anti-Slip Stair Solutions in Industrial Safety

In diverse industrial and commercial environments, ensuring the safety of personnel and visitors is paramount. Stairs, often high-traffic areas, present inherent slip and fall hazards, especially when exposed to moisture, grease, or heavy foot traffic. This necessitates the implementation of robust safety measures. anti slip stair strips emerge as a foundational component in mitigating these risks, offering enhanced traction and visibility. Their strategic deployment not only prevents accidents but also significantly reduces potential liability and operational disruptions caused by injuries. These essential safety components are engineered to provide superior grip on stair treads, crucial for maintaining safe access and egress in facilities ranging from manufacturing plants and petrochemical refineries to educational institutions and public transport hubs. Understanding their design, material science, and application versatility is key for B2B decision-makers.

The market for industrial safety products, including solutions like anti slip stair strips, is experiencing consistent growth, driven by increasingly stringent occupational health and safety regulations worldwide, alongside a heightened awareness of workplace ergonomics and accident prevention. Industry reports indicate a significant year-over-year increase in demand for durable and effective anti-slip solutions, reflecting a proactive approach by businesses to safeguard their assets and human capital. This trend underscores the shift from reactive accident response to proactive risk management strategies, where investing in high-quality stair safety components is recognized as a vital long-term operational investment. The integration of advanced materials and innovative design methodologies continues to refine the performance and longevity of these critical safety elements.

Manufacturing Excellence: Crafting Durable Anti-Slip Solutions

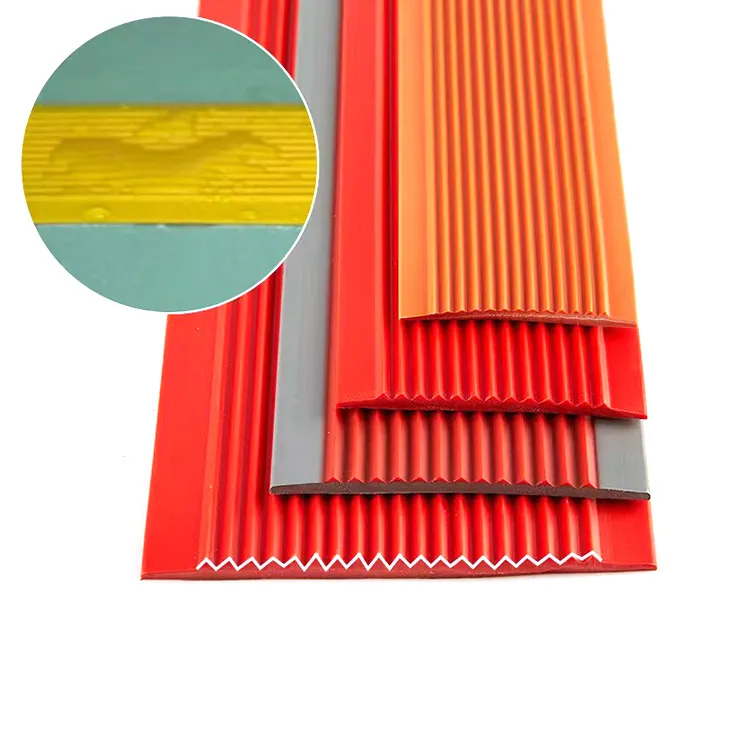

The production of high-performance anti slip stair strips, especially those designed for industrial and high-traffic environments, involves a meticulous manufacturing process that prioritizes material integrity, precision engineering, and adherence to stringent quality controls. For our Plastic Rubber Stair Nose Edge Trim, the primary material is a high-grade, virgin PVC (Polyvinyl Chloride) and EPDM (Ethylene Propylene Diene Monomer) blend, specifically engineered for optimal durability, flexibility, and resistance to environmental degradation. This material choice is critical as it offers superior resistance to abrasion, chemicals, UV radiation, and temperature fluctuations, surpassing the performance of standard rubbers in specific applications. The manufacturing process typically begins with the compounding of raw polymer granules with specialized additives, including UV stabilizers, flame retardants, and anti-aging agents, which enhance the product's lifespan and performance characteristics.

The compounded material then undergoes an extrusion process, where it is heated and forced through a die to form the desired profile of the stair nose edge trim. This method ensures consistent dimensional accuracy and a uniform material density throughout the length of the strip. Following extrusion, the strips are cooled, often in a water bath, to set their shape and prevent deformation. Subsequent steps involve precision cutting to specified lengths, followed by the application of any necessary surface treatments, such as an embossed or grooved anti-slip pattern, which is crucial for maximizing friction. Quality control checks are integrated at every stage, from raw material inspection to final product verification. These checks include hardness testing (e.g., Shore A durometer), tensile strength evaluation, dimensional accuracy checks, and slip resistance coefficient measurements, often performed under various conditions (wet, dry, oily) to meet international standards such like ANSI A1264.2 (Standard for Slip Resistance of Walking/Working Surfaces) and ISO 23871 (Safety of machinery - Anti-slip surfaces). The life expectancy of these strips, when properly installed and maintained, can exceed 10-15 years, depending on traffic volume and environmental exposure.

Technical Specifications and Performance Metrics

Understanding the technical specifications of safety stair strips is essential for selecting the appropriate product for specific operational requirements. Our Plastic Rubber Stair Nose Edge Trim is engineered to meet rigorous performance standards, offering a balance of durability, flexibility, and superior anti-slip properties. Key parameters include material composition, dimensional stability, coefficient of friction (COF), temperature resistance, and chemical compatibility. The COF is a critical indicator of slip resistance, with higher values signifying better traction; our products are designed to exceed industry minimums for both wet and dry conditions, ensuring optimal safety in various environments. The robust material formulation also contributes to excellent abrasion resistance, which is vital in high-traffic commercial and industrial settings where wear and tear are significant factors.

The design incorporates specific geometries to facilitate ease of installation and secure fit, minimizing displacement even under heavy loads. This precision engineering contributes to the overall longevity and effectiveness of the stair edge protector. Below is a comprehensive table detailing typical technical parameters for high-quality anti-slip stair strips, including those relevant to our plastic rubber solutions, allowing for a clear comparison of critical attributes. These metrics are derived from extensive testing and ensure compliance with global safety benchmarks, offering peace of mind to facility managers and procurement specialists.

| Parameter | Description | Typical Value (Plastic Rubber) | Standard Met |

|---|---|---|---|

| Material Composition | High-grade PVC/EPDM blend | Virgin Polymer with additives | ASTM D2240 (Hardness), ASTM D412 (Tensile) |

| Hardness (Shore A) | Resistance to indentation | 70-90A | ISO 7619-1 |

| Coefficient of Friction (COF) - Dry | Measure of slip resistance on dry surface | > 0.65 | ANSI A1264.2, ASTM E303 |

| Coefficient of Friction (COF) - Wet | Measure of slip resistance on wet surface | > 0.50 | ANSI A1264.2, ASTM E303 |

| Temperature Range | Operational temperature limits | -20°C to +60°C | ISO 3386 |

| Abrasion Resistance | Resistance to wear from friction | Excellent (low material loss) | ASTM D1630 (Taber Abrasion) |

| Chemical Resistance | Resistance to common industrial chemicals | Good to Excellent (Acids, Alkalis, Oils) | ISO 175 |

| UV Stability | Resistance to degradation from sunlight | High (non-fading, non-cracking) | ASTM G154 |

Versatile Application Scenarios and Industry Benefits

The adaptability of anti slip stair strips makes them indispensable across a broad spectrum of industries, each with unique safety demands. In manufacturing and industrial facilities, where heavy machinery and fluid spills are common, these strips provide critical traction on steel or concrete stairs, preventing injuries that could lead to costly downtime. In the petrochemical industry, their corrosion resistance is paramount, as exposure to harsh chemicals and solvents can rapidly degrade lesser materials. Similarly, within the metallurgy sector, which deals with extreme temperatures and abrasive dust, robust rubber edging for stairs or appropriate alternatives maintain safety despite challenging conditions. Furthermore, in public service sectors such as schools and healthcare facilities, where a diverse population uses stairs daily, the soft yet durable nature of plastic rubber strips enhances comfort and reduces noise, while primarily ensuring a safe passage.

Beyond traditional industrial applications, the Plastic Rubber Stair Nose Edge Trim is ideally suited for commercial buildings, retail spaces, residential complexes, and even marine environments. Their superior grip is especially beneficial in areas prone to wet conditions, such as outdoor staircases, entrances, or areas frequently cleaned. The inherent material properties of these strips, particularly their PVC/EPDM blend, offer notable advantages. They are inherently resistant to a wide range of corrosive agents and biological growth, reducing the need for frequent replacement and extensive maintenance, thereby contributing to long-term cost savings and operational efficiency. This durability translates to a lower total cost of ownership (TCO) compared to less robust alternatives. Moreover, the flexibility of rubber allows for effective shock absorption, reducing impact noise, which is particularly beneficial in noise-sensitive environments like offices or educational settings.

Comparative Analysis: Metal vs. Rubber/Plastic Stair Edging

When selecting stair safety solutions, B2B clients often weigh the benefits of different material types. The primary contenders are often metal edging for stairs and rubber or plastic edging. While metal options, typically aluminum or stainless steel, offer high rigidity and can withstand extremely heavy impact loads, they often come with higher material costs and can become slippery when wet or worn, potentially requiring additional abrasive inserts. Installation of metal strips can also be more complex, often requiring drilling and mechanical fastening, which may damage the stair substrate. Furthermore, metal can conduct heat and cold, potentially affecting ambient temperatures or becoming uncomfortable to touch in extreme climates. Its primary advantage lies in extreme durability against mechanical abuse and a sleek aesthetic suitable for certain architectural designs.

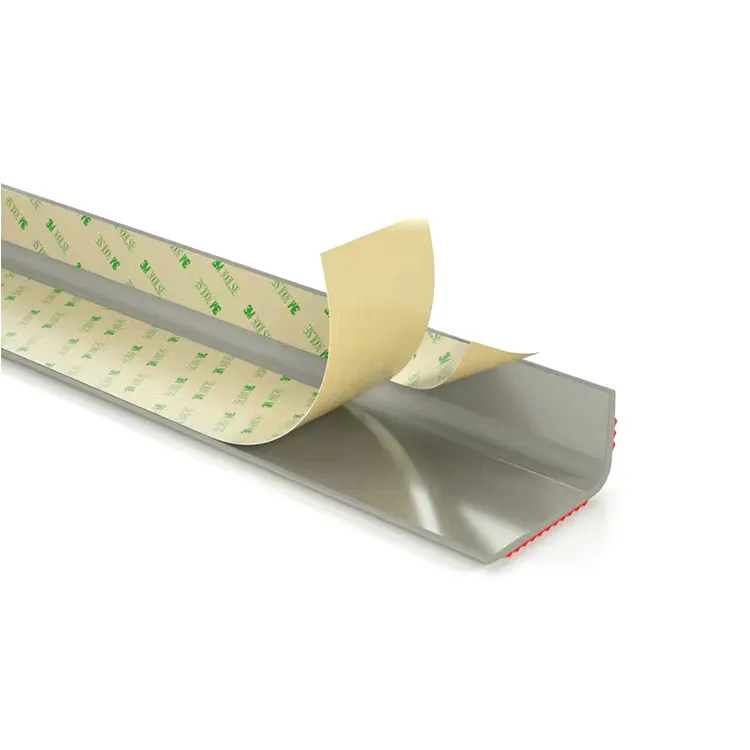

In contrast, plastic and rubber edging for stairs, such as our PVC/EPDM blend, excel in providing consistent high traction, especially in wet conditions, due to their inherent material properties and textured surfaces. They offer superior sound dampening, reducing noise from foot traffic, which is highly valued in educational, healthcare, and office environments. These materials are also inherently non-corrosive, making them ideal for outdoor applications or areas exposed to moisture and chemicals without risk of rust or degradation. Installation is typically simpler, often involving adhesive bonding, which is less invasive to the stair structure. While not designed for extreme impact resistance like some heavy-duty metal variants, their flexibility provides cushioning, reducing fatigue on stairs and protecting the stair nosing from chips and cracks. Our solutions represent a cost-effective, high-performance alternative, providing excellent long-term value, superior slip resistance, and easier maintenance.

| Feature | Metal Edging for Stairs (e.g., Aluminum) | Rubber/Plastic Edging (e.g., PVC/EPDM) |

|---|---|---|

| Slip Resistance (Wet) | Moderate (can be slippery, needs inserts) | Excellent (inherently high COF) |

| Corrosion Resistance | Good (some alloys) to Excellent (stainless steel) | Excellent (non-corrosive) |

| Impact Resistance | Very High | High (flexible, absorbs impact) |

| Noise Reduction | Low | High (sound dampening) |

| Installation Complexity | Moderate to High (drilling, fasteners) | Low (adhesive, easy cutting) |

| Cost (Material) | Higher | Moderate (excellent value) |

| Aesthetic Range | Sleek, Metallic | Diverse colors, subtle integration |

Customization and Real-World Implementation

Recognizing that every industrial or commercial application has unique requirements, manufacturers of high-quality anti slip stair strips offer extensive customization options. This includes varying dimensions (width, height, thickness), a broad spectrum of colors to match interior aesthetics or comply with safety coding (e.g., yellow for caution), and specific surface textures to optimize slip resistance for particular environments. For instance, a facility dealing with oil or grease might require a more aggressive texture than a school hallway. Customization also extends to materials, with options for fire-retardant additives, anti-microbial treatments for healthcare settings, or enhanced UV resistance for outdoor installations in sunny climates. This bespoke approach ensures that clients receive a solution perfectly tailored to their operational needs, maximizing both safety and aesthetic integration.

Our track record includes numerous successful deployments where our Plastic Rubber Stair Nose Edge Trims have significantly enhanced safety. In a major educational district, a project involved retrofitting thousands of stair treads across multiple school buildings. The previous solution, traditional metal nosing, had proven inadequate in preventing slips on damp days and contributed to excessive noise. By implementing our flexible plastic rubber solution, the district reported a 60% reduction in minor slip-related incidents over the first year, alongside a noticeable decrease in ambient noise levels. Another case involved a large-scale renovation of a municipal building where high foot traffic necessitated a durable yet safe solution. Our customized colors and lengths allowed for seamless integration with existing décor while providing superior slip protection, demonstrating the product's versatility and performance in diverse public environments.

Ensuring Trust: Quality, Certifications, and Support

For B2B procurement, trust is built upon a foundation of proven quality, adherence to international standards, and robust customer support. Our manufacturing processes for anti slip stair strips are rigorously audited to ISO 9001:2015 quality management standards, ensuring consistency and excellence from raw material sourcing to final product delivery. Beyond this, our products regularly undergo independent third-party testing to validate their performance characteristics, including slip resistance, durability, and chemical compatibility, often meeting or exceeding certifications like ADA compliance for accessibility and various fire safety ratings. We maintain a strong commitment to environmental responsibility, with our materials and processes aiming for reduced ecological impact where feasible, further enhancing their appeal for companies with sustainability initiatives.

Our dedication to customer satisfaction extends beyond product quality to comprehensive support services. We offer detailed technical specifications, installation guides, and access to our expert engineering team for project consultation. Our standard delivery cycle typically ranges from 2 to 4 weeks for standard orders, with expedited options available for urgent requirements, ensuring minimal disruption to client project timelines. A standard 5-year limited warranty covers manufacturing defects and material degradation under normal use, reflecting our confidence in the longevity and performance of our Plastic Rubber Stair Nose Edge Trim. Post-installation, our client support team remains accessible for any inquiries or assistance, solidifying our role as a reliable partner in workplace safety solutions.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of these plastic rubber stair edge protectors?

A1: Our Plastic Rubber Stair Nose Edge Trims are designed for exceptional durability. With proper installation and maintenance, they typically have a service life of 10 to 15 years, even in high-traffic commercial or industrial settings. This longevity is attributed to the high-grade PVC/EPDM blend which offers superior resistance to abrasion, UV radiation, and chemical exposure.

Q2: Are these anti slip stair strips suitable for outdoor use?

A2: Yes, absolutely. The PVC/EPDM material blend provides excellent resistance to weathering, UV degradation, and temperature fluctuations. This makes them highly suitable for outdoor staircases, ramps, and other exterior applications where slip hazards are a concern due to rain, snow, or direct sunlight. Their non-corrosive nature also ensures they won't rust or degrade like some metal alternatives.

Q3: How do these strips compare to abrasive tape or painted anti-slip coatings?

A3: While abrasive tapes and painted coatings offer immediate, albeit often temporary, slip resistance, our plastic rubber safety stair strips provide a far more durable and long-term solution. Tapes and paints can wear off quickly in high-traffic areas, requiring frequent reapplication and maintenance. Our strips offer a physical, robust barrier that maintains consistent anti-slip properties over years, providing superior edge protection and a cleaner, more professional appearance without the constant need for reapplication.

Q4: Can these rubber edging for stairs be customized in terms of color or size?

A4: Yes, we offer extensive customization options to meet specific project requirements. This includes a wide range of standard and custom colors to match branding or architectural designs, as well as various dimensions (width, height, thickness) to fit different stair types and applications. We also provide options for specific performance enhancements, such as fire retardancy or anti-microbial properties, depending on the industry and usage environment. Please contact our sales team to discuss your custom needs.

Conclusion

In conclusion, the strategic implementation of high-quality anti slip stair strips is an indispensable investment for any facility prioritizing safety, operational efficiency, and long-term cost-effectiveness. Our Plastic Rubber Stair Nose Edge Trim exemplifies the pinnacle of modern safety engineering, combining advanced material science with precise manufacturing processes to deliver a product that exceeds industry benchmarks. From its superior slip resistance and exceptional durability to its ease of installation and versatile application across diverse industries, this solution offers a comprehensive approach to mitigating slip and fall hazards. By choosing a robust, certified, and customizable product like ours, businesses not only safeguard their personnel and comply with critical safety regulations but also enhance the overall integrity and longevity of their infrastructure. We are committed to partnering with B2B clients to provide tailored, high-performance safety solutions that address their specific operational challenges and contribute to a safer environment for everyone.

References

- National Safety Council. (2023). Workplace Injuries and Fatalities: A Comprehensive Review.

- ASTM International. (2022). Standard Test Method for Measuring Slip Resistance of Pedestrian Surfaces (ASTM E303-22).

- Occupational Safety and Health Administration (OSHA). (2021). Walking-Working Surfaces and Personal Fall Protection Systems (29 CFR Part 1910, Subpart D).

- ISO (International Organization for Standardization). (2020). Safety of machinery – Anti-slip surfaces (ISO 23871:2020).

- American Society for Testing and Materials. (2023). Standard Test Method for Rubber Property—Durometer Hardness (ASTM D2240-23).

-

Durable Seal for Oven Door: Perfect Fit, Energy EfficiencyNewsSep.01,2025

-

Durable Silicone Strip Seals: Premium Weather & Door SealingNewsAug.31,2025

-

Premium Seal for Oven Door | Maximize Heat & Energy EfficiencyNewsAug.30,2025

-

Premium Anti Slip Stair Strips: Enhance Safety & Prevent FallsNewsAug.29,2025

-

Clear Corner Protectors: Child Safety for Tables & EdgesNewsAug.28,2025

-

Weather Stripping Door Standard Sizes and Custom CutsNewsAug.12,2025

-

Seal for Oven Door Cleaning and Maintenance TipsNewsAug.12,2025