automotive door seal adhesive

The Significance of Automotive Door Seal Adhesive Ensuring Quality and Performance

Automotive door seal adhesives play a vital role in the manufacturing and maintenance of vehicles. These adhesives are essential for providing tight seals around car doors, preventing water, dust, and noise from entering the vehicle's cabin. A robust seal enhances passenger comfort and contributes to the overall quality and performance of the automobile. This article delves into the significance, types, and application processes of automotive door seal adhesives.

Importance of Door Seals

Door seals, also known as weatherstripping, are crucial components of any vehicle. They serve multiple purposes

1. Water Resistance The primary function of door seals is to prevent water ingress. A well-sealed vehicle will keep rain and moisture out, preserving the interior and preventing rust damage to metal parts over time.

2. Noise Reduction Automotive door seal adhesives also help in acoustical insulation. They minimize the amount of road noise and wind sound that enters the cabin, enhancing the driving experience and reducing driver fatigue.

3. Thermal Insulation Properly installed door seals contribute to temperature regulation inside the vehicle. Effective seals keep the heating and cooling systems efficient, resulting in better fuel economy for internal combustion engine vehicles.

4. Dust and Debris Barrier In addition to being waterproof, door seals protect against dirt, dust, and other environmental elements. This is particularly important for off-road vehicles or those operating in harsh climates.

Types of Automotive Door Seal Adhesives

There are several types of adhesives used in automotive door seals, each with its unique properties and applications

1. Polyurethane Adhesives Known for their strong bonding capabilities and flexibility, polyurethane adhesives can endure extreme temperatures and weather conditions. Their versatility makes them suitable for a variety of substrates used in vehicle construction.

2. Silicone Adhesives Silicone adhesives offer excellent resistance to moisture and temperature fluctuations. They are often used in applications where a high-performance seal is required, particularly in vehicles exposed to harsh climates.

automotive door seal adhesive

3. Acrylic Adhesives Acrylics provide a strong initial tack and quick curing times, making them ideal for assembly line applications. They offer good resistance to UV light and aging, ensuring longevity in outdoor exposures.

4. Rubber-based Adhesives These adhesives maintain elasticity and flexibility, making them suitable for use in areas exposed to vibrations and movements. They are commonly used in sealing applications where durability is essential.

Application Process

Applying automotive door seal adhesive requires precision and attention to detail. Here’s a general overview of the process

1. Surface Preparation The surfaces to which the seals will be applied must be cleaned thoroughly. Any dirt, grease, or old adhesive residues must be removed to ensure a proper bond.

2. Adhesive Selection Based on the application requirements, the appropriate adhesive type should be chosen. Factors such as temperature resistance, substrate compatibility, and environmental exposure will influence this decision.

3. Application The adhesive is applied evenly to the designated area. This can be done using various methods such as spraying, brushing, or using a dedicated applicator. It’s crucial to apply the right amount of adhesive to avoid oozing and ensure a uniform seal.

4. Seal Placement The door seal is then positioned precisely, ensuring that it aligns correctly with the door frame. Adequate pressure should be applied as needed to facilitate adhesion.

5. Curing Time Depending on the adhesive type, there will be a recommended curing time before the door is operated. This allows the adhesive to reach its full bonding strength.

6. Quality Check Finally, a quality check should be performed to ensure that the seal is properly installed and effective. This may involve visual inspections and water leakage tests.

Conclusion

Automotive door seal adhesives are more than just a bonding material; they are critical to the performance and comfort of vehicles. Investing in quality adhesives and ensuring their proper application can lead to a significant improvement in vehicle durability and passenger satisfaction. As automotive technology evolves, the development of advanced adhesives will continue to play a pivotal role in enhancing the driving experience. Whether for manufacturing or maintenance purposes, understanding the significance of these adhesives is essential for industry professionals and car owners alike.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

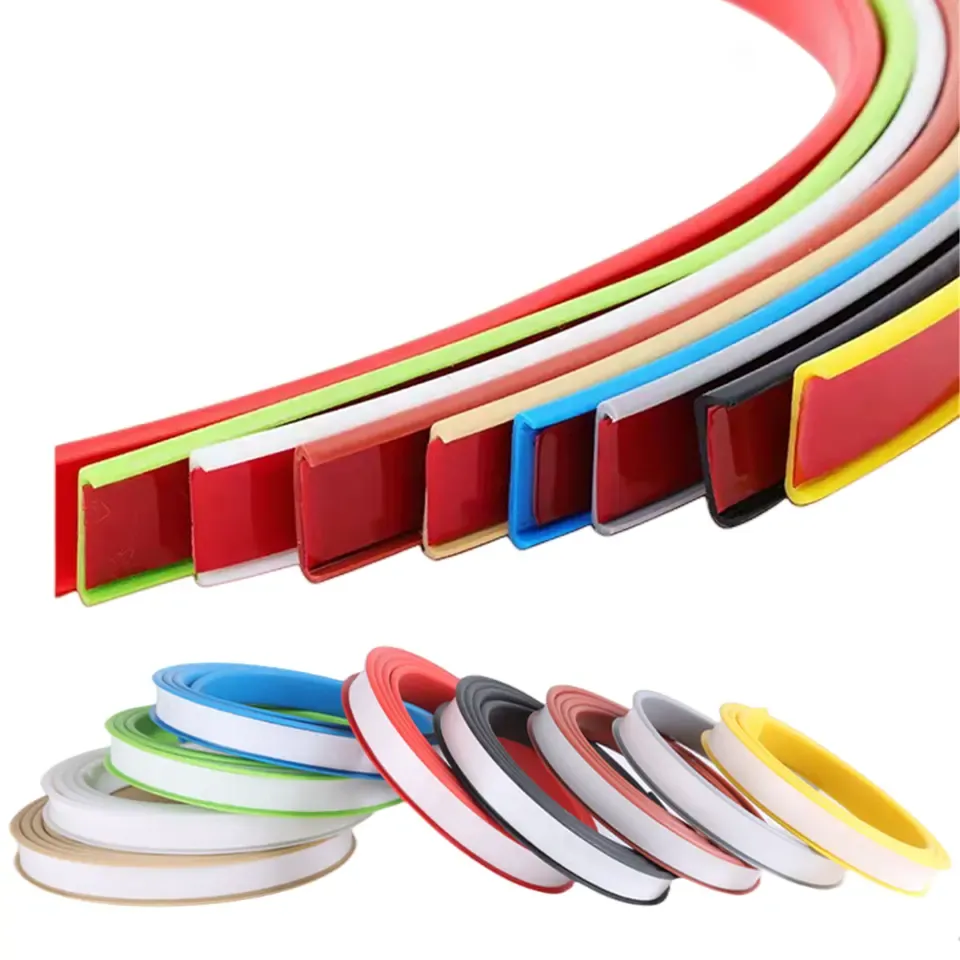

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025