Telephone: +8618730949119

E-mail: 1299343081@qq.com

Jan . 29, 2025 01:26

Back to list

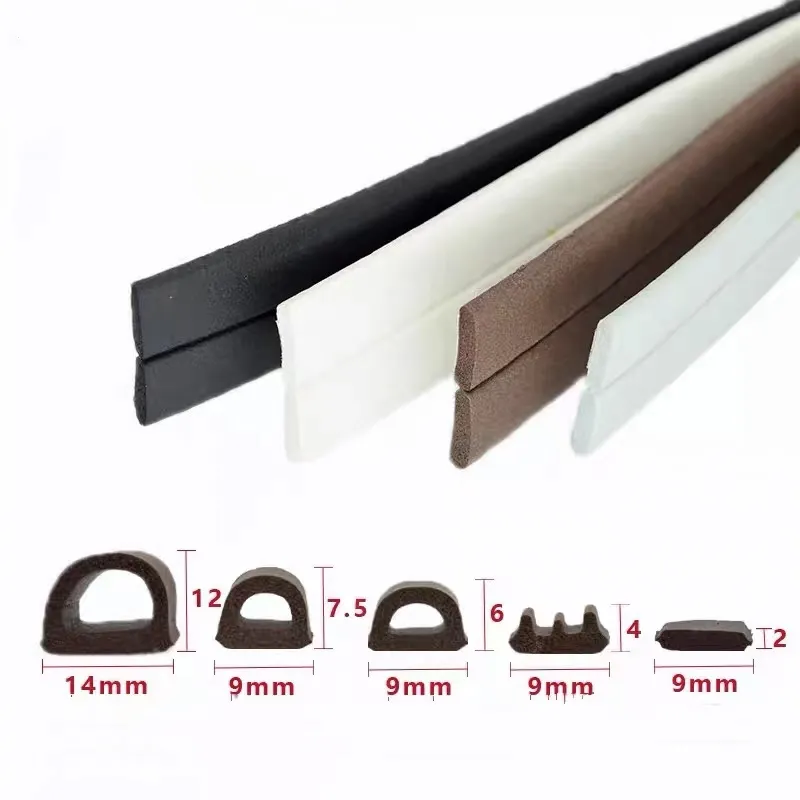

automotive rubber door seals

Automotive rubber door seals play a crucial role in the overall performance and comfort of vehicles. These components may seem minor, but their impact on vehicle operation, safety, and user experience is significant.

In terms of safety and regulatory standards, automotive rubber door seals also play a role in enhancing crashworthiness. Properly functioning seals contribute to the structural integrity of doors, particularly in side-impact scenarios, thereby ensuring better protection for occupants. Manufacturers must comply with stringent safety regulations, which dictate the materials and structural specifications that automotive seals must meet. The evolution of smart vehicles brings about new opportunities and challenges for rubber door seals manufacturers. Intelligent sealing systems are being developed that integrate sensors to monitor seal integrity in real-time. These advancements allow for predictive maintenance, alerting when seals need replacement before failure occurs, thus enhancing vehicle safety and user satisfaction. For professionals in the automotive industry, the production and application of rubber door seals demand a deep understanding of both material science and automotive engineering. Staying ahead in the development of innovative seal designs not only meets regulatory criteria but also addresses consumer demands for quieter, energy-efficient, and safer vehicles. In conclusion, automotive rubber door seals are not just functional necessities but are integral to the user experience, vehicle performance, and safety standards compliance. As vehicles continue to advance towards greater automation and efficiency, the importance of cutting-edge door seal technology will only increase. Manufacturers and engineers must continue to innovate and uphold high-quality standards to meet the evolving demands of the automotive industry.

In terms of safety and regulatory standards, automotive rubber door seals also play a role in enhancing crashworthiness. Properly functioning seals contribute to the structural integrity of doors, particularly in side-impact scenarios, thereby ensuring better protection for occupants. Manufacturers must comply with stringent safety regulations, which dictate the materials and structural specifications that automotive seals must meet. The evolution of smart vehicles brings about new opportunities and challenges for rubber door seals manufacturers. Intelligent sealing systems are being developed that integrate sensors to monitor seal integrity in real-time. These advancements allow for predictive maintenance, alerting when seals need replacement before failure occurs, thus enhancing vehicle safety and user satisfaction. For professionals in the automotive industry, the production and application of rubber door seals demand a deep understanding of both material science and automotive engineering. Staying ahead in the development of innovative seal designs not only meets regulatory criteria but also addresses consumer demands for quieter, energy-efficient, and safer vehicles. In conclusion, automotive rubber door seals are not just functional necessities but are integral to the user experience, vehicle performance, and safety standards compliance. As vehicles continue to advance towards greater automation and efficiency, the importance of cutting-edge door seal technology will only increase. Manufacturers and engineers must continue to innovate and uphold high-quality standards to meet the evolving demands of the automotive industry.

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025