Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 12, 2025 22:46

Back to list

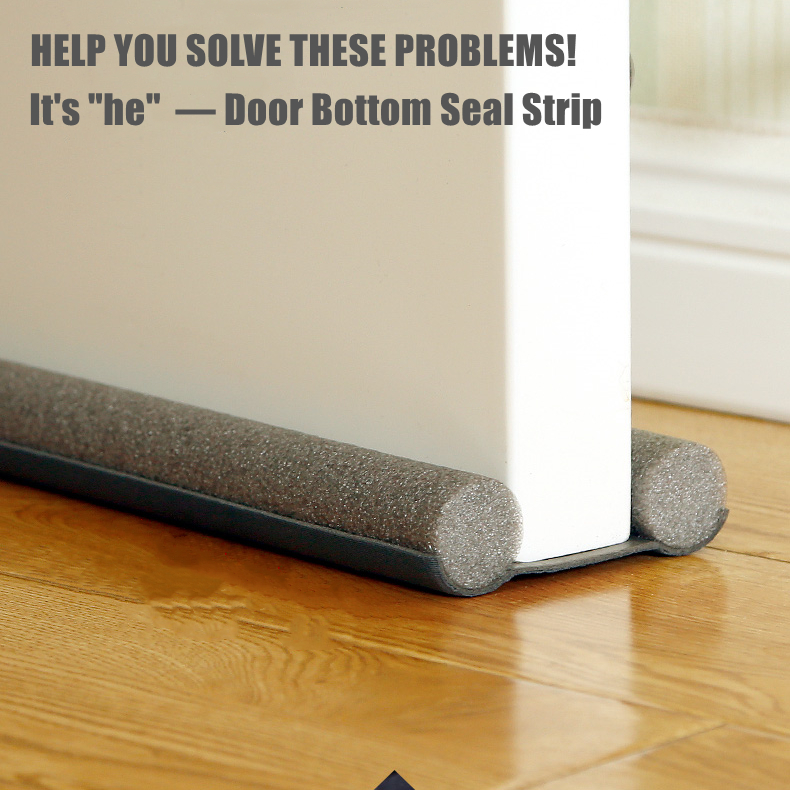

door bottom seal rubber strip

Navigating the world of sealing solutions can be daunting, especially when seeking the ideal product to eliminate drafts, noise, or dust. The black rubber seal strip emerges as an unsung hero in these situations, offering unique qualities that cater to a range of sealing needs. Possessing a deep understanding of these strips can significantly optimize efficiency and durability in various applications.

For businesses contemplating the integration of black rubber seal strips, knowledge is a powerful tool. Partnering with established suppliers who possess a proven track record in delivering quality products is crucial. These providers not only ensure consistent product quality but also offer insights into customized solutions tailored to specific requirements. Their expertise becomes invaluable, guiding businesses through the selection process based on application needs, environmental conditions, and industry standards. The trustworthiness of a supplier is underscored by certifications and adherence to rigorous industry standards. ISO certification, for instance, is a hallmark of quality assurance, giving businesses confidence in their vendor's capability to meet stringent quality criteria. Engaging with certified suppliers mitigates risks associated with product failure, further solidifying the reliability of black rubber seal strips in operations. In conclusion, the strategic application of black rubber seal strips can revitalize operational efficiency, reduce costs, and promote sustainability. Their expert design, combined with material resilience, places them as a cornerstone in sealing solutions. As businesses seek reliable and efficient sealing methods, incorporating black rubber seal strips offers a fulfillment of expectations in performance, reliability, and environmental responsibility, making them an unparalleled choice in today's dynamic industrial landscape. Engaging with knowledgeable suppliers and understanding the core benefits of these strips can significantly enhance their value, offering long-term advantages in various applications.

For businesses contemplating the integration of black rubber seal strips, knowledge is a powerful tool. Partnering with established suppliers who possess a proven track record in delivering quality products is crucial. These providers not only ensure consistent product quality but also offer insights into customized solutions tailored to specific requirements. Their expertise becomes invaluable, guiding businesses through the selection process based on application needs, environmental conditions, and industry standards. The trustworthiness of a supplier is underscored by certifications and adherence to rigorous industry standards. ISO certification, for instance, is a hallmark of quality assurance, giving businesses confidence in their vendor's capability to meet stringent quality criteria. Engaging with certified suppliers mitigates risks associated with product failure, further solidifying the reliability of black rubber seal strips in operations. In conclusion, the strategic application of black rubber seal strips can revitalize operational efficiency, reduce costs, and promote sustainability. Their expert design, combined with material resilience, places them as a cornerstone in sealing solutions. As businesses seek reliable and efficient sealing methods, incorporating black rubber seal strips offers a fulfillment of expectations in performance, reliability, and environmental responsibility, making them an unparalleled choice in today's dynamic industrial landscape. Engaging with knowledgeable suppliers and understanding the core benefits of these strips can significantly enhance their value, offering long-term advantages in various applications.

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025