Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 11, 2025 14:12

Back to list

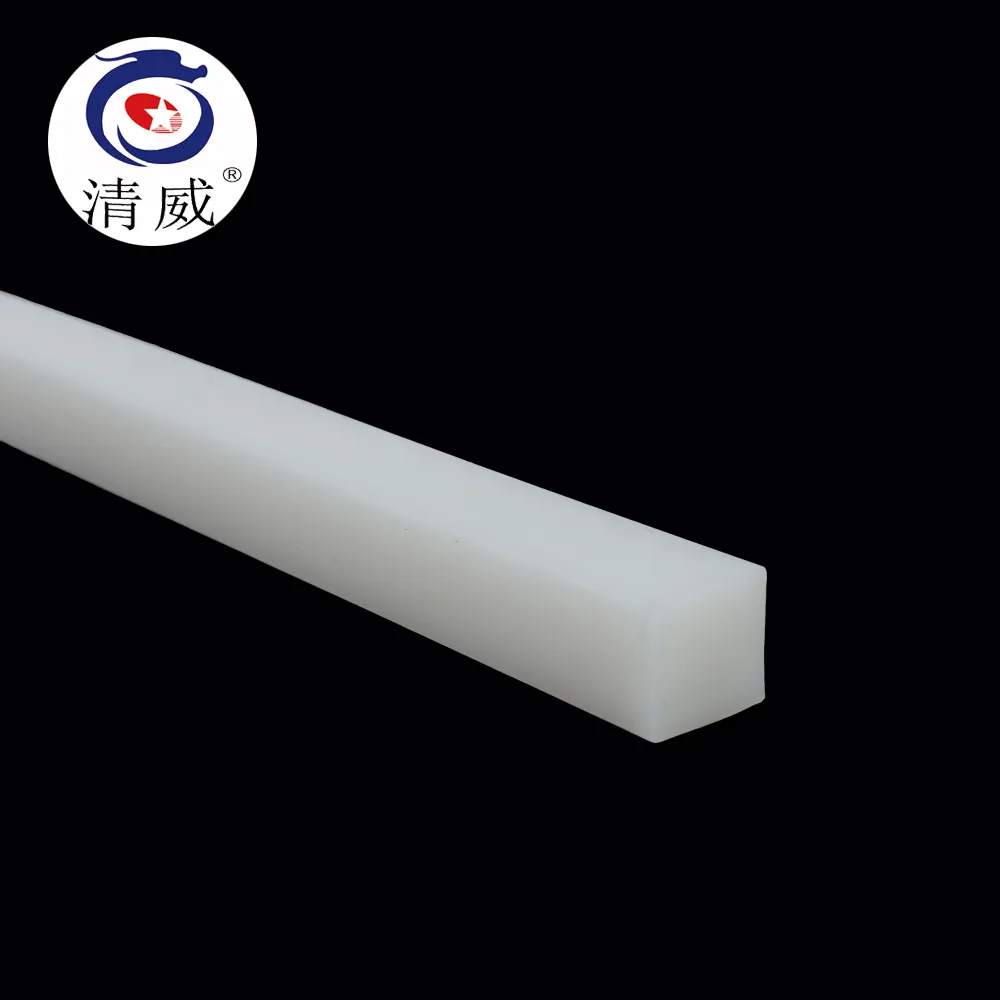

bulb rubber seal

Understanding the intricate world of bulb rubber seals is crucial for professionals engaged in automotive, aerospace, and industrial sectors. These seemingly mundane components embody the principles of experience, expertise, authoritativeness, and trustworthiness, making them indispensable for any mechanical assembly requiring robust sealing solutions.

From an experience standpoint, companies with decades of expertise in manufacturing these seals have honed their processes to deliver products that consistently exceed expectations. Customer testimonials and case studies corroborate the durability and functional benefits of their products, enhancing the brand's reputation and authority in the market. Extensive testing under realistic conditions adds an extra layer of confidence, assuring stakeholders of the seal's effectiveness. Quality control procedures are rigorous, reflecting the industry’s commitment to excellence. Every bulb rubber seal undergoes multiple stages of verification, including dimensional accuracy checks, material purity tests, and performance simulations. Such diligence guarantees that only products meeting the highest standards reach the market, enhancing consumer trust and satisfaction. Bulb rubber seals are more than mere product components; they represent a fusion of experience with leading-edge technology. Their evolving designs integrate with next-generation mechanical systems, reducing noise, vibration, and harshness, pivotal in industries where precision and quiet operation are crucial. The ongoing advancements in bulb seal technology also point to the sustainable aspect of product development, aligning with global movements towards environmental consciousness. By selecting recyclable and lower-impact materials, the industry is moving towards reducing its ecological footprint, playing a role in corporate responsibility missions. In conclusion, bulb rubber seals stand as paragons of engineering proficiency. They incorporate the fundamentals of experience, expertise, authoritativeness, and trustworthiness within their design and application. Continual innovation and unwavering dedication to quality have cemented their status as vital elements across various industries, where failure is not an option, and reliability is paramount.

From an experience standpoint, companies with decades of expertise in manufacturing these seals have honed their processes to deliver products that consistently exceed expectations. Customer testimonials and case studies corroborate the durability and functional benefits of their products, enhancing the brand's reputation and authority in the market. Extensive testing under realistic conditions adds an extra layer of confidence, assuring stakeholders of the seal's effectiveness. Quality control procedures are rigorous, reflecting the industry’s commitment to excellence. Every bulb rubber seal undergoes multiple stages of verification, including dimensional accuracy checks, material purity tests, and performance simulations. Such diligence guarantees that only products meeting the highest standards reach the market, enhancing consumer trust and satisfaction. Bulb rubber seals are more than mere product components; they represent a fusion of experience with leading-edge technology. Their evolving designs integrate with next-generation mechanical systems, reducing noise, vibration, and harshness, pivotal in industries where precision and quiet operation are crucial. The ongoing advancements in bulb seal technology also point to the sustainable aspect of product development, aligning with global movements towards environmental consciousness. By selecting recyclable and lower-impact materials, the industry is moving towards reducing its ecological footprint, playing a role in corporate responsibility missions. In conclusion, bulb rubber seals stand as paragons of engineering proficiency. They incorporate the fundamentals of experience, expertise, authoritativeness, and trustworthiness within their design and application. Continual innovation and unwavering dedication to quality have cemented their status as vital elements across various industries, where failure is not an option, and reliability is paramount.

Next:

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025