Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 16, 2025 02:12

Back to list

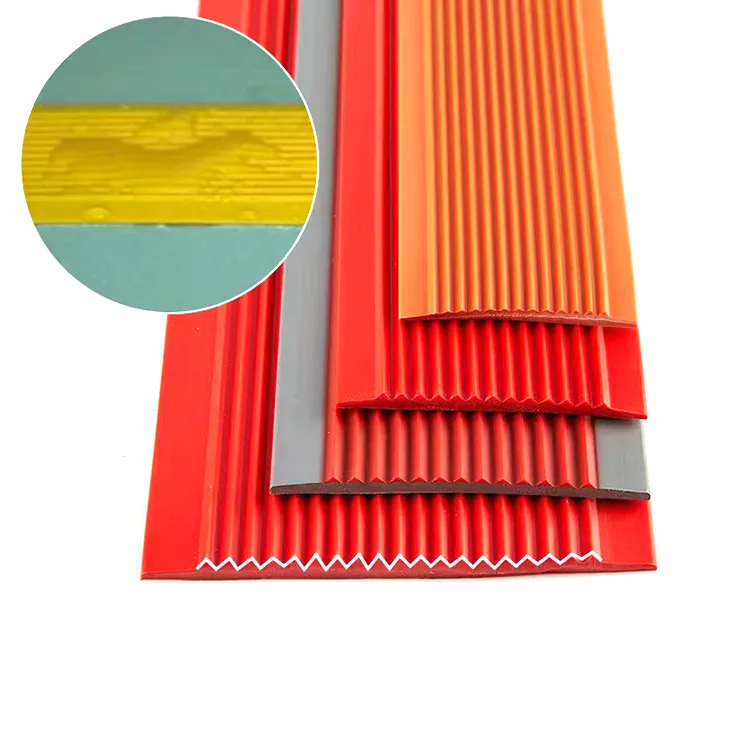

Plastic Rubber Stair Nose Edge Trim,Stair Step Edging Protection Decoration Guard For School And Home Use

Navigating the ever-evolving landscape of interior design and furniture making calls for a keen understanding of not just aesthetics but also the functionality of materials. One such unsung hero in this realm is chipboard edging tape, a product that's quietly revolutionizing how we approach finishing touches on furniture and construction projects. Its seamless integration into various design elements not only elevates the visual appeal but also extends the lifespan of the structures it adorns.

Moreover, chipboard edging tape's role extends beyond aesthetics and protection. It is an expression of trustworthiness in craftsmanship. When a piece of furniture is completed with expertly applied edging, it signals attention to detail and a commitment to quality. Clients, ranging from homeowners to large-scale commercial buyers, recognize the value of such diligence in their purchasing decisions. They associate well-executed edge finishes with longevity and superior performance, reinforcing customer satisfaction and brand loyalty. For professionals seeking to deepen their understanding of chipboard products, attending workshops or engaging with peer-reviewed studies can provide invaluable insights. Journals that focus on material science or industry-specific publications often offer detailed analyses on the advancements in adhesive technologies or surface treatments related to edging tapes. This wealth of information underlines the continual innovation in product development, showcasing the dynamic nature of this seemingly humble component. Furthermore, real-world testimonials and case studies amplify the experience metric in the context of chipboard edging tape. Testimonials from satisfied users, whether they be seasoned carpenters or enthusiastic DIYers, highlight practical applications and problem-solving scenarios that offer potential customers authentic and relatable insights. For instance, a small furniture maker might share how switching to a particular brand of environmentally-friendly tape helped them reduce production waste while maintaining the integrity and look of their pieces. In conclusion, chipboard edging tape stands as a testament to the synergy of expertise and experience in the furniture industry. Its application is a nuanced art that enhances both form and function, confirming its indispensable nature in high-quality furniture design. Therefore, for any business or hobbyist focused on achieving excellence in craftsmanship, investing in top-tier edging solutions is not just advisable but essential. By doing so, they not only uphold the highest standards of quality and aesthetics but also contribute to a more sustainable and value-driven future in design and manufacturing.

Moreover, chipboard edging tape's role extends beyond aesthetics and protection. It is an expression of trustworthiness in craftsmanship. When a piece of furniture is completed with expertly applied edging, it signals attention to detail and a commitment to quality. Clients, ranging from homeowners to large-scale commercial buyers, recognize the value of such diligence in their purchasing decisions. They associate well-executed edge finishes with longevity and superior performance, reinforcing customer satisfaction and brand loyalty. For professionals seeking to deepen their understanding of chipboard products, attending workshops or engaging with peer-reviewed studies can provide invaluable insights. Journals that focus on material science or industry-specific publications often offer detailed analyses on the advancements in adhesive technologies or surface treatments related to edging tapes. This wealth of information underlines the continual innovation in product development, showcasing the dynamic nature of this seemingly humble component. Furthermore, real-world testimonials and case studies amplify the experience metric in the context of chipboard edging tape. Testimonials from satisfied users, whether they be seasoned carpenters or enthusiastic DIYers, highlight practical applications and problem-solving scenarios that offer potential customers authentic and relatable insights. For instance, a small furniture maker might share how switching to a particular brand of environmentally-friendly tape helped them reduce production waste while maintaining the integrity and look of their pieces. In conclusion, chipboard edging tape stands as a testament to the synergy of expertise and experience in the furniture industry. Its application is a nuanced art that enhances both form and function, confirming its indispensable nature in high-quality furniture design. Therefore, for any business or hobbyist focused on achieving excellence in craftsmanship, investing in top-tier edging solutions is not just advisable but essential. By doing so, they not only uphold the highest standards of quality and aesthetics but also contribute to a more sustainable and value-driven future in design and manufacturing.

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025