Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 14, 2025 19:58

Back to list

High Performance Oven Door Silicone Seal Strip

When it comes to maintaining the efficiency and durability of your kitchen appliances, often the most overlooked component is the cooker oven seal. These seemingly insignificant parts are an integral element in the oven's functionality, optimally sealing in heat to ensure consistent cooking results and energy efficiency. Through personal experience, industry expertise, and detailed studies, understanding the nuances of cooker oven seals can transform your everyday cooking endeavors.

Replacing an oven seal might seem daunting, yet it is a straightforward procedure that most can undertake without professional intervention. Generally, the task involves removing the old seal, cleaning the embedding track of residual debris, and pressing the replacement seal into place. A correctly installed seal not only prevents heat from escaping but also restricts the entry of cold air, thus maintaining a stable internal environment for diverse cooking processes. It is advisable to consult your oven's manual or manufacturer’s guidelines to ensure proper installation practices. It is essential to periodically inspect the seal for signs of damage such as tears, hardening, or significant wear. Regular assessment can preemptively highlight issues before they morph into costly complications. Trustworthiness in recommendation stems from understanding these indicators, backed by authoritative insights from leading appliance brands confirming that periodic maintenance prolongs the lifespan of your oven. In conclusion, the health of your cooker oven seal is indicative of the overall performance and reliability of your kitchen appliance. Leveraging expert advice, corroborated by real-world experience, underscores the need to not only choose the right seal but also maintain it judiciously. A well-maintained oven seal promises superior cooking performance, aligns with sustainable energy use, and fortifies your investment in quality home cooking experiences. As with any appliance element, the key to longevity and efficiency lies in proactive care and timely intervention, ensuring that your kitchen endeavors are both rewarding and resource-efficient.

Replacing an oven seal might seem daunting, yet it is a straightforward procedure that most can undertake without professional intervention. Generally, the task involves removing the old seal, cleaning the embedding track of residual debris, and pressing the replacement seal into place. A correctly installed seal not only prevents heat from escaping but also restricts the entry of cold air, thus maintaining a stable internal environment for diverse cooking processes. It is advisable to consult your oven's manual or manufacturer’s guidelines to ensure proper installation practices. It is essential to periodically inspect the seal for signs of damage such as tears, hardening, or significant wear. Regular assessment can preemptively highlight issues before they morph into costly complications. Trustworthiness in recommendation stems from understanding these indicators, backed by authoritative insights from leading appliance brands confirming that periodic maintenance prolongs the lifespan of your oven. In conclusion, the health of your cooker oven seal is indicative of the overall performance and reliability of your kitchen appliance. Leveraging expert advice, corroborated by real-world experience, underscores the need to not only choose the right seal but also maintain it judiciously. A well-maintained oven seal promises superior cooking performance, aligns with sustainable energy use, and fortifies your investment in quality home cooking experiences. As with any appliance element, the key to longevity and efficiency lies in proactive care and timely intervention, ensuring that your kitchen endeavors are both rewarding and resource-efficient.

Latest news

-

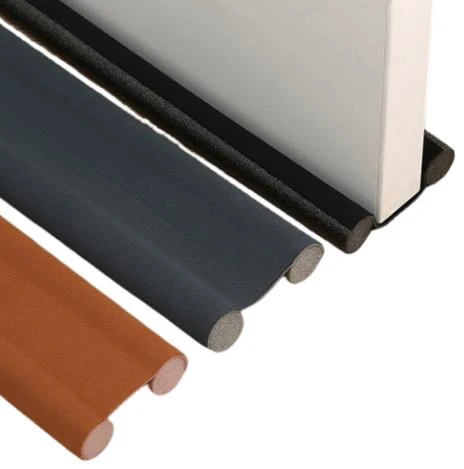

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

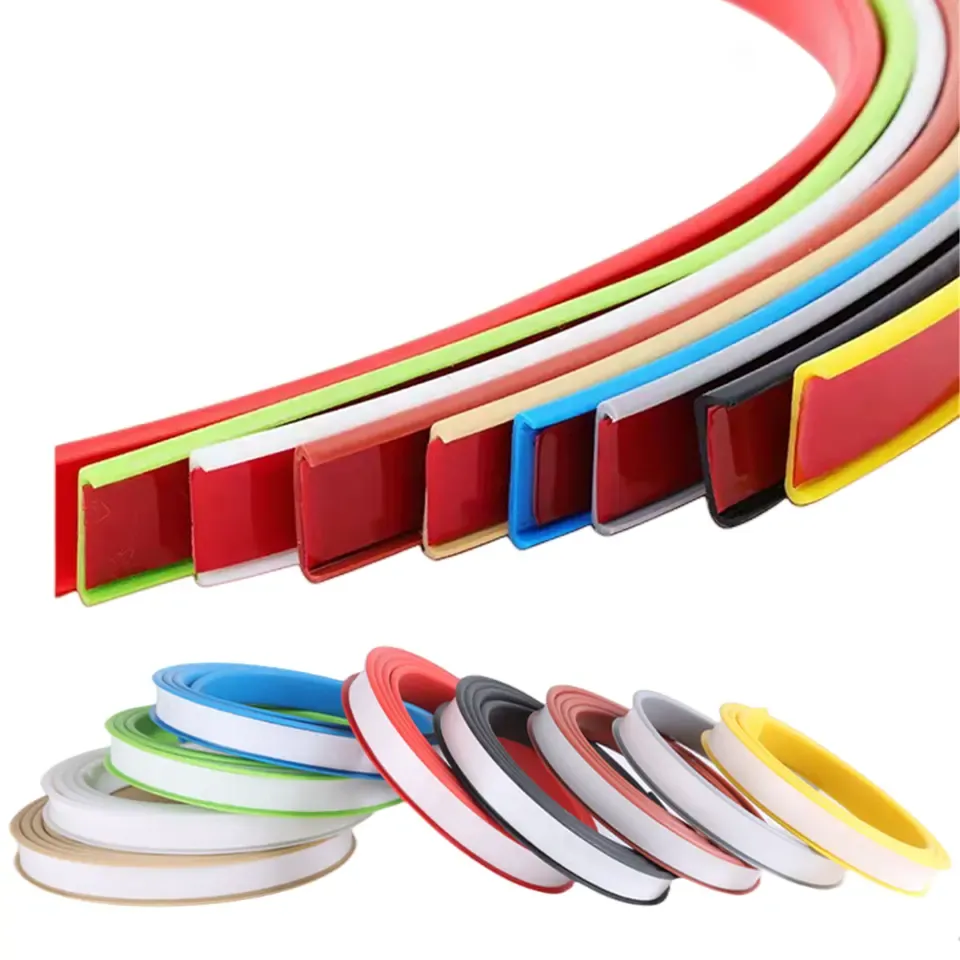

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025