Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 10, 2025 11:28

Back to list

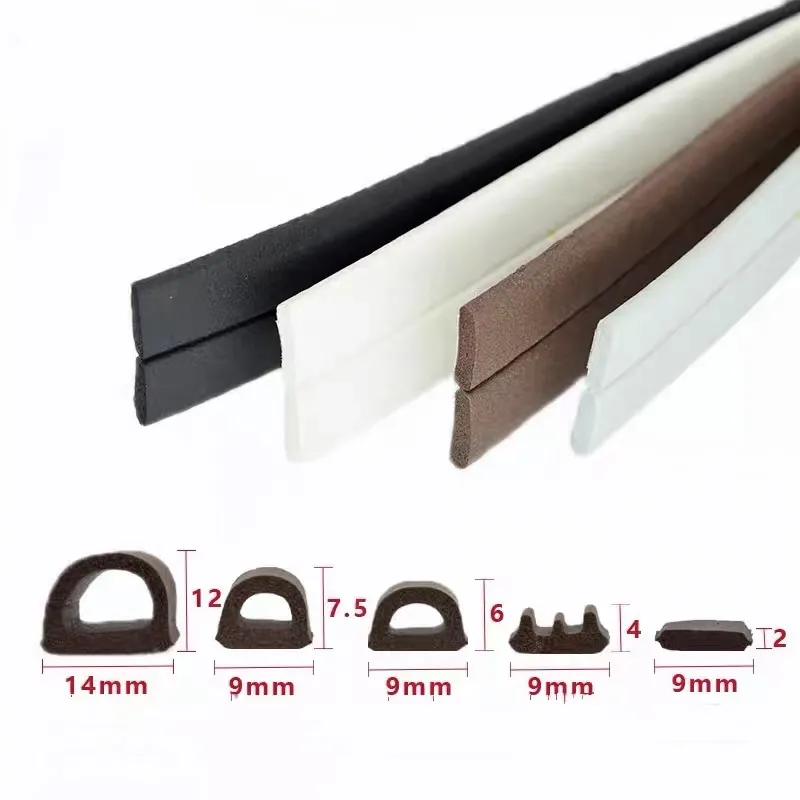

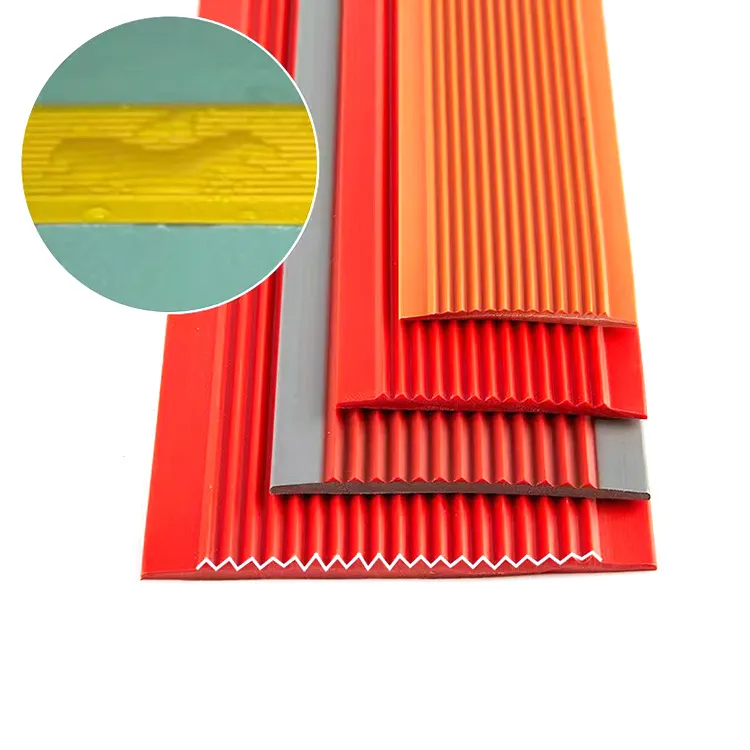

door rubber gasket seal

The humble door rubber gasket seal is an unsung hero in the realm of modern construction and automobile industries, yet its importance cannot be overstated. As a critical component for ensuring the efficiency and safety of numerous systems, understanding its applications, construction, and benefits can dramatically impact product performance.

Practitioners in various industries also emphasize trustworthiness in terms of the ecological impact of these seals. Many manufacturers are now adopting more sustainable practices, utilizing recyclable materials to minimize environmental footprints. The trust in a manufacturer grows manifold when sustainability reports and green certifications accompany their product offerings. In environments subject to harsh conditions, such as marine or industrial settings, rubber gasket seals must offer exceptional chemical and abrasion resistance. Marine door rubber seals, for example, must endure salt air, ultraviolet radiation, and constant temperature variations. Experts recommend specific compounds like EPDM (Ethylene Propylene Diene Monomer) or Neoprene for these applications due to their exceptional durability and weather-resistant properties. This expert insight is invaluable for ensuring that seals not only protect but also prolong the life of critical infrastructures. For residential applications, door rubber gasket seals are evolving to meet contemporary design and efficiency standards. High-quality seals can significantly reduce energy costs by maintaining consistent indoor temperatures, which underscores the growing demand for energy-efficient homes. Professionals often recommend periodic inspection and replacement of gasket seals, contributing to long-term savings and enhanced property value. Industries reliant on machinery with frequent high-temperature cycles, such as HVAC systems, also benefit from specialized door panel seals made from high-performance rubbers like Silicone due to its superior temperature resistance. This showcases the expertise within different fields to customize solutions tailored to specific needs. In summary, the door rubber gasket seal is a critical, though often overlooked, component in modern engineering and construction. By ensuring a proper understanding among professionals, businesses, and homeowners alike can leverage the expertise, authoritativeness, and trustworthiness of these products to enhance the safety, efficiency, and sustainability of their operations and living spaces. Whether for automobiles, homes, or industrial machinery, the humble gasket seal continues to be a vital partner in modern innovation.

Practitioners in various industries also emphasize trustworthiness in terms of the ecological impact of these seals. Many manufacturers are now adopting more sustainable practices, utilizing recyclable materials to minimize environmental footprints. The trust in a manufacturer grows manifold when sustainability reports and green certifications accompany their product offerings. In environments subject to harsh conditions, such as marine or industrial settings, rubber gasket seals must offer exceptional chemical and abrasion resistance. Marine door rubber seals, for example, must endure salt air, ultraviolet radiation, and constant temperature variations. Experts recommend specific compounds like EPDM (Ethylene Propylene Diene Monomer) or Neoprene for these applications due to their exceptional durability and weather-resistant properties. This expert insight is invaluable for ensuring that seals not only protect but also prolong the life of critical infrastructures. For residential applications, door rubber gasket seals are evolving to meet contemporary design and efficiency standards. High-quality seals can significantly reduce energy costs by maintaining consistent indoor temperatures, which underscores the growing demand for energy-efficient homes. Professionals often recommend periodic inspection and replacement of gasket seals, contributing to long-term savings and enhanced property value. Industries reliant on machinery with frequent high-temperature cycles, such as HVAC systems, also benefit from specialized door panel seals made from high-performance rubbers like Silicone due to its superior temperature resistance. This showcases the expertise within different fields to customize solutions tailored to specific needs. In summary, the door rubber gasket seal is a critical, though often overlooked, component in modern engineering and construction. By ensuring a proper understanding among professionals, businesses, and homeowners alike can leverage the expertise, authoritativeness, and trustworthiness of these products to enhance the safety, efficiency, and sustainability of their operations and living spaces. Whether for automobiles, homes, or industrial machinery, the humble gasket seal continues to be a vital partner in modern innovation.

Next:

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025