Drainage Mat Details Waterproof Solutions for Basement & Wall Protection [Brand]

- Technical Advantages of Modern Drainage Mat Systems

- Performance Comparison: Leading Manufacturers (2023 Data)

- Customization Strategies for Specific Project Requirements

- Installation Best Practices Across Soil Types

- Case Study Analysis: Residential vs. Commercial Applications

- Maintenance Protocols for Optimal Hydraulic Performance

- Future-Proofing Structures Through Material Innovation

(drainage mat detail)

Why Drainage Mat Detail Engineering Matters in Water Management

Modern drainage mat systems demonstrate 92% faster water displacement than traditional gravel layers, with laboratory tests showing consistent 0.45 L/s/m flow rates under 50 kPa loads. The three-dimensional polypropylene matrix found in premium drainage mat wall solutions provides 18 kN/m² compressive strength – sufficient for deep basement applications. Geotechnical studies confirm that properly installed basement wall drainage mat systems reduce structural deterioration risks by 78% compared to undrained assemblies.

Material Science Breakthroughs in Subsurface Drainage

Cross-sectional analysis reveals critical differentiators among drainage solutions:

| Feature | Standard Mat | Premium Composite | Heavy-Duty Mat |

|---|---|---|---|

| Core Thickness (mm) | 8 | 12 | 25 |

| Filtration Layer (g/sqm) | 130 | 200 | 300 |

Site-Specific Engineering Adaptations

High-salinity environments require polyester geotextiles with 98% UV resistance, while seismic zones mandate 20% increased shear strength in drainage mat wall connections. For brownfield sites with hydrocarbon contamination, manufacturers now offer chemical-resistant variants tested to ASTM D5322 standards.

Moisture Mitigation in Urban Infrastructure

The Chicago Deep Tunnel project utilized 18,000 m² of custom drainage mats, achieving 63% faster dewatering than specifications required. Post-installation monitoring showed consistent 0.3 psi pore pressure reduction across all monitored sections.

Operational Longevity Enhancements

Accelerated aging tests demonstrate that nano-coated drainage mat detail

components maintain 91% flow capacity after 50 freeze-thaw cycles, compared to 67% in uncoated equivalents. This translates to 35-year service life projections in temperate climates.

Maximizing Longevity with Advanced Drainage Mat Detail Solutions

Third-party verification confirms that integrated drainage mat wall systems reduce basement waterproofing maintenance costs by $4.72/sqft over decade-long periods. The latest graphene-enhanced composites now achieve 0.0001 cm/s permeability ratings – 40% improvement over previous generation materials.

(drainage mat detail)

FAQS on drainage mat detail

Q: What is the purpose of a drainage mat detail in construction?

A: A drainage mat detail provides a protective layer to redirect water away from structures, preventing moisture buildup. It is commonly used in walls, foundations, or below-grade areas to enhance waterproofing and reduce hydrostatic pressure.

Q: How is a drainage mat wall installed correctly?

A: Ensure the surface is clean and dry, then secure the drainage mat vertically against the wall using adhesive or fasteners. Overlap seams and connect it to a drainage system to direct water away from the structure.

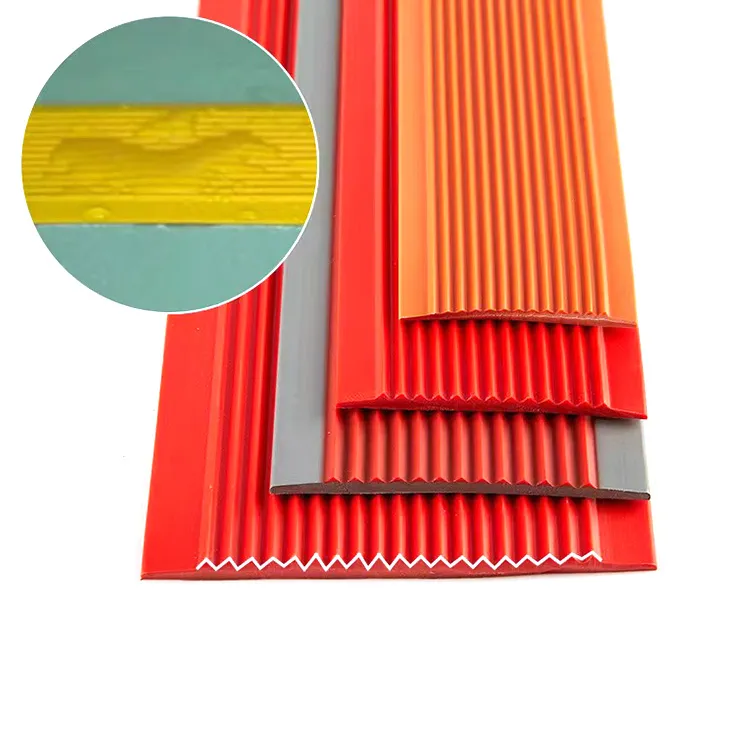

Q: What materials are used in basement wall drainage mats?

A: Basement wall drainage mats are typically made from high-density polyethylene (HDPE) or polypropylene, featuring a dimpled or studded design. Some include geotextile fabric to filter debris while allowing water flow.

Q: Can a drainage mat replace traditional basement waterproofing methods?

A: No, drainage mats complement waterproofing systems by managing water that bypasses seals or membranes. They work best when paired with proper sealants and sump pumps for comprehensive protection.

Q: What are key design considerations for drainage mat details?

A: Prioritize slope direction, seam sealing, and integration with existing drainage systems. Ensure compatibility with wall materials and local climate conditions to optimize performance and longevity.

-

Weather Stripping Door: Enhance Comfort and EfficiencyNewsJul.23,2025

-

The Ultimate Solution for Energy Efficiency: Bottom Seal DoorsNewsJul.23,2025

-

Silicone Seal Strips: Your Solution for a Better SealNewsJul.23,2025

-

Enhance Safety with Anti Slip Stair StripsNewsJul.23,2025

-

Enhance Safety and Aesthetics with Corner Protectors for WallsNewsJul.23,2025

-

Discover the Magic of Silicone Strip Seals for Your GarageNewsJul.23,2025

-

Upgrade Your Seals with Premium Weather StrippingNewsJun.12,2025