Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 05, 2025 06:20

Back to list

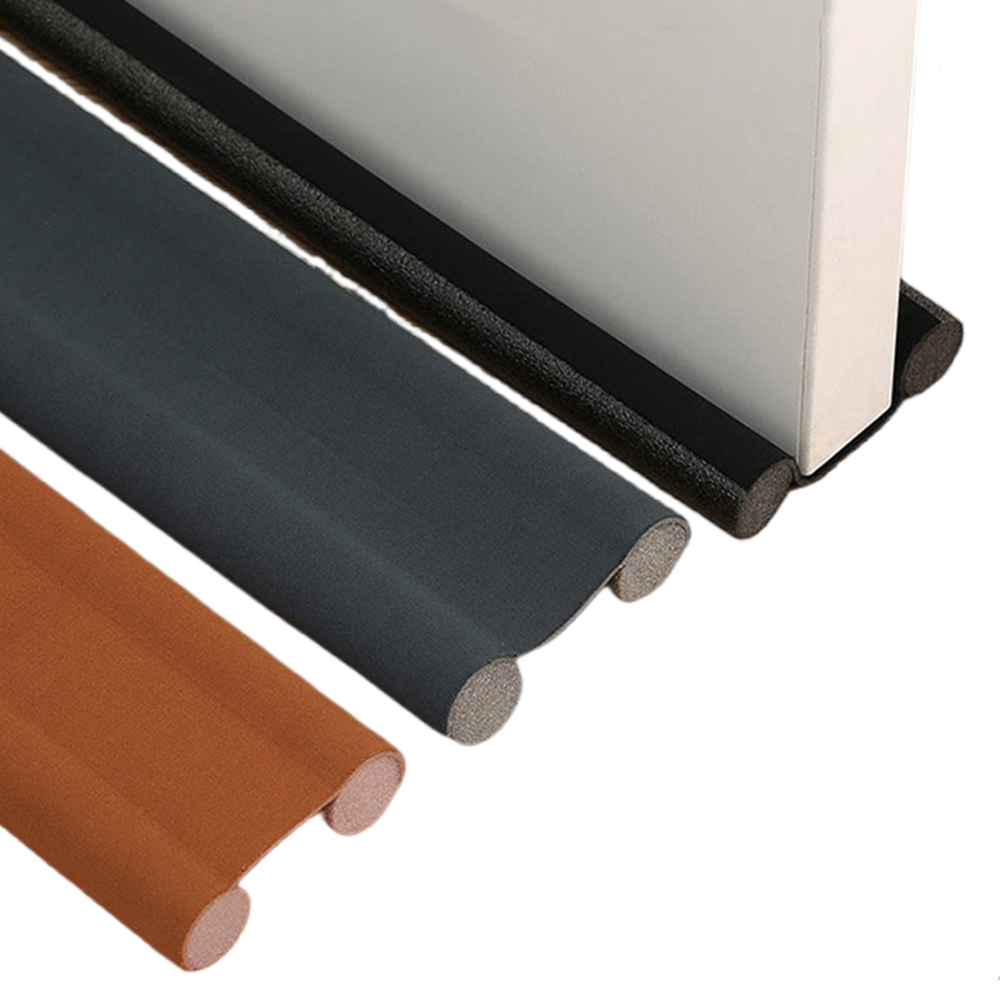

d shaped rubber seal

In the realm of sealing solutions, the D-shaped rubber seal stands out as a versatile and essential component in various industries. From automotive to construction, its unique profile and material properties make it a go-to choice for myriad applications. This article delves into the experience, expertise, authoritativeness, and trustworthiness of D-shaped rubber seals, highlighting their unparalleled utility and importance.

Trustworthiness, a cornerstone of any significant industrial component, is evidenced in the D-shaped rubber seal's track record. Customers across varying sectors have repeatedly vouched for their efficacy, citing years of maintenance-free operation. The rubber seal's robust nature and the manufacturers' commitment to quality foster trust, ensuring that end-users can rely on these products for critical applications. In industrial practice, the installation and maintenance of D-shaped rubber seals are straightforward, further cementing their practicality and reliability. Their compatibility with a range of surfaces and substrates allows for easy integration into existing systems, reducing downtime and operational impacts during replacement or upgrades. Moreover, advancements in rubber compounding and manufacturing technologies continue to enhance the performance characteristics of D-shaped rubber seals. These innovations include improved abrasion resistance and the integration of antimicrobial agents, broadening the seals' applicability to sectors such as healthcare and food processing, where hygiene is paramount. D-shaped rubber seals have earned their place as indispensable components across industries. By embodying the principles of experience, expertise, authoritativeness, and trustworthiness, they not only meet but often exceed the demanding expectations of industrial applications. Their ongoing evolution, driven by technological advancements and rigorous quality standards, promises to sustain their relevance and reliability well into the future. Industry professionals and end-users alike can remain confident in their choice of D-shaped rubber seals, assured by a legacy of excellence and an unwavering commitment to performance.

Trustworthiness, a cornerstone of any significant industrial component, is evidenced in the D-shaped rubber seal's track record. Customers across varying sectors have repeatedly vouched for their efficacy, citing years of maintenance-free operation. The rubber seal's robust nature and the manufacturers' commitment to quality foster trust, ensuring that end-users can rely on these products for critical applications. In industrial practice, the installation and maintenance of D-shaped rubber seals are straightforward, further cementing their practicality and reliability. Their compatibility with a range of surfaces and substrates allows for easy integration into existing systems, reducing downtime and operational impacts during replacement or upgrades. Moreover, advancements in rubber compounding and manufacturing technologies continue to enhance the performance characteristics of D-shaped rubber seals. These innovations include improved abrasion resistance and the integration of antimicrobial agents, broadening the seals' applicability to sectors such as healthcare and food processing, where hygiene is paramount. D-shaped rubber seals have earned their place as indispensable components across industries. By embodying the principles of experience, expertise, authoritativeness, and trustworthiness, they not only meet but often exceed the demanding expectations of industrial applications. Their ongoing evolution, driven by technological advancements and rigorous quality standards, promises to sustain their relevance and reliability well into the future. Industry professionals and end-users alike can remain confident in their choice of D-shaped rubber seals, assured by a legacy of excellence and an unwavering commitment to performance.

Next:

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025