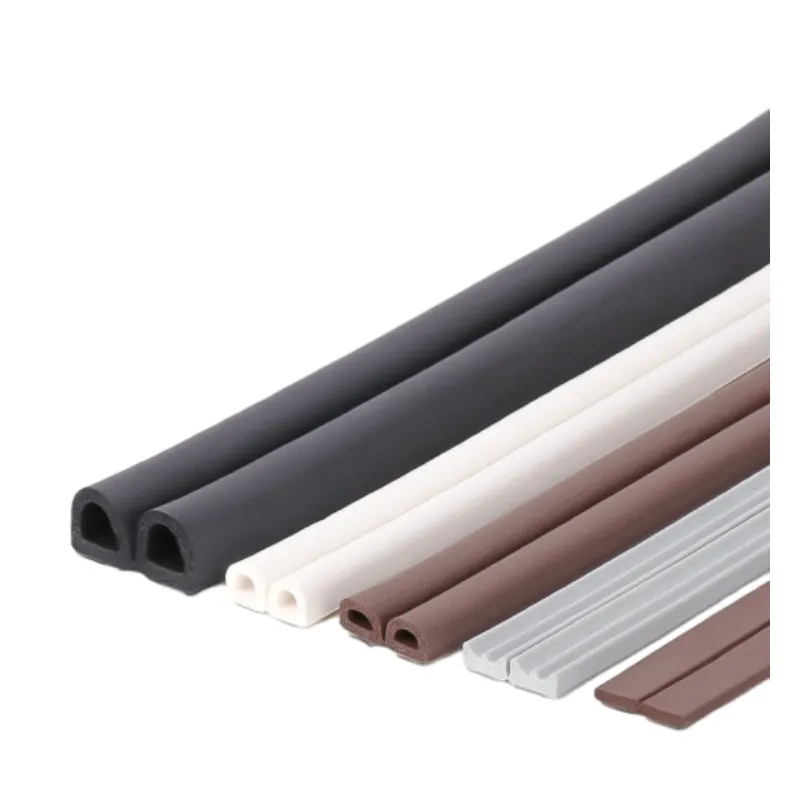

D-Shaped Silicone Seal for Effective Weatherproofing and Noise Reduction Solutions

The Advantages of D-Shaped Silicone Seals An In-Depth Look

In the world of engineering and manufacturing, sealing solutions play a crucial role in ensuring the integrity and functionality of products. Among the various sealing options available, D-shaped silicone seals have gained significant attention due to their unique design and versatility. This article explores the features, advantages, and applications of D-shaped silicone seals, making them a preferred choice in various industries.

Understanding D-Shaped Silicone Seals

D-shaped silicone seals are named for their distinctive profile, which resembles the letter D. This shape is achieved through a cross-sectional design that combines a flat base with a rounded top. The geometry of these seals allows them to fit snugly into designated grooves, providing a reliable barrier against various environmental factors such as moisture, dust, and air.

The primary material used in the production of these seals is silicone, a synthetic polymer known for its exceptional durability, flexibility, and resistance to extreme temperatures. Silicone can withstand a wide range of temperatures, typically from -60°C to 200°C (-76°F to 392°F), making D-shaped silicone seals suitable for applications in both high and low-temperature environments.

Key Advantages of D-Shaped Silicone Seals

1. Versatile Compatibility D-shaped silicone seals can be used in a variety of applications across multiple industries, including automotive, aerospace, electronics, and construction. Their adaptability makes them an ideal choice for different sealing needs, whether it’s in machinery, HVAC systems, or consumer goods.

2. Excellent Weather Resistance One of the standout features of silicone is its ability to resist degradation due to exposure to UV light, ozone, and various weather conditions. This characteristic is particularly beneficial for outdoor applications, where seals experience constant exposure to harsh environmental factors.

d shaped silicone seal

3. Chemical Resistance D-shaped silicone seals offer superior resistance to many chemicals, oils, and solvents. This property makes them suitable for use in industries such as food processing and pharmaceuticals, where contamination and chemical corrosion are significant concerns.

4. Easy Installation The design of D-shaped silicone seals allows for straightforward installation. Their flat base enables a secure fit in grooves, often requiring minimal tooling or equipment for effective placement. This ease of installation can lead to reduced labor costs and quicker assembly times in manufacturing processes.

5. Long Service Life The durability of silicone contributes to a long service life for D-shaped seals. Unlike many other rubber materials, silicone does not harden or crack with age, ensuring that the seals maintain their effectiveness over time and reducing the need for frequent replacements.

Applications in Various Industries

D-shaped silicone seals are widely employed in numerous applications. In the automotive industry, they are used in windows, doors, and engine components to provide sound insulation and prevent leaks. In aerospace, these seals protect sensitive electronic equipment from dust and moisture. Additionally, they are essential in HVAC systems, ensuring energy efficiency by sealing ducts and preventing air leaks.

In consumer goods, D-shaped silicone seals are used in kitchen appliances, ensuring airtight seals that preserve food freshness. Furthermore, their application in medical devices is increasingly recognized, as their biocompatibility and sterility make them suitable for sensitive healthcare environments.

Conclusion

D-shaped silicone seals offer a blend of versatility, durability, and ease of use that make them indispensable in various industries. Their ability to withstand extreme conditions and resist environmental challenges positions them as a reliable sealing solution for modern engineering needs. As technology and manufacturing continue to evolve, the demand for effective sealing solutions like D-shaped silicone seals will likely only grow, ensuring that they remain at the forefront of innovative design and application.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025