Exploring the Versatility and Applications of E3 Edgebands in Furniture Design

The Evolution and Importance of E3 Edgebanding

In the world of modern furniture design and interior finishing, the details make all the difference. One such detail that often goes unnoticed but plays a crucial role in both aesthetics and functionality is the edgebanding. Among the different types of edgebanding available, E3 edgebanding has gained significant attention for its innovative properties and practical applications. This article explores the evolution, benefits, and significance of E3 edgebanding within the furniture industry.

What is E3 Edgebanding?

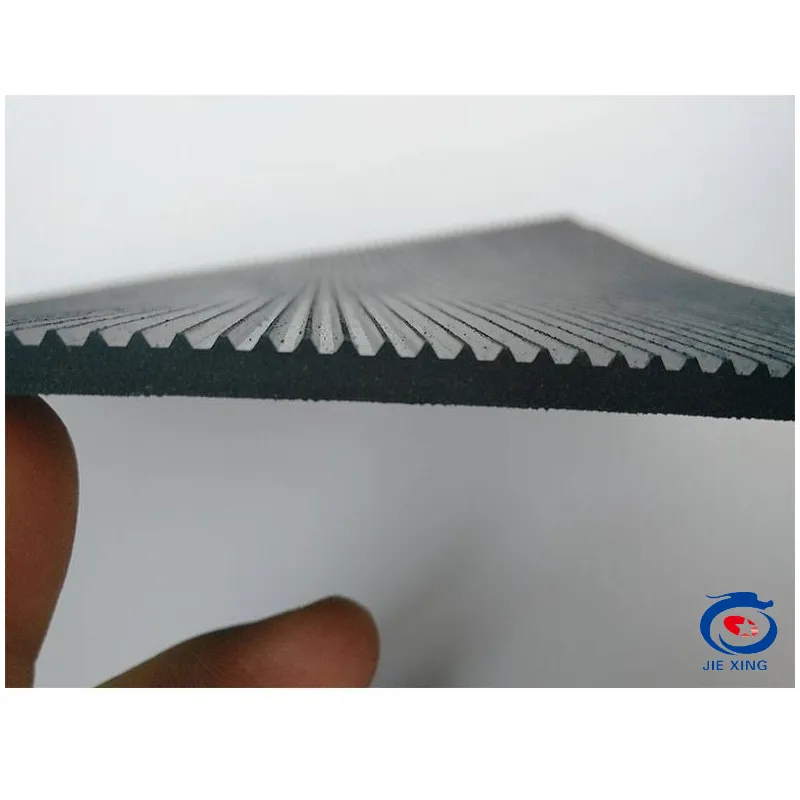

E3 edgebanding is a specialized type of edge treatment used in the manufacturing of furniture and cabinetry. It is designed to cover the exposed edges of composite wood panel products, such as medium-density fiberboard (MDF) and particleboard. The term E3 refers to a specific standard of edgebanding characterized by its high durability, strong adhesive properties, and resistance to moisture and chemicals. This makes it an ideal choice for various applications, from kitchen cabinets to office furniture.

The Evolution of Edgebanding

The concept of edgebanding has undergone significant changes over the years. Traditionally, wooden edge banding or vinyl tapes were commonly used, which provided a basic level of protection and aesthetic appeal. However, these materials often fell short in terms of durability and ease of application. With the advancement of technology and materials, E3 edgebanding emerged as a superior alternative.

E3 edgebanding is manufactured using advanced processes and composites that enhance its performance. The introduction of various finishes, colors, and textures has also expanded the design possibilities for furniture manufacturers. This evolution has allowed designers to achieve a polished and professional look while ensuring that their products meet strict quality standards.

Benefits of E3 Edgebanding

1. Durability One of the standout features of E3 edgebanding is its durability. It is designed to withstand the rigors of daily use, ensuring that the edges of furniture remain intact and visually appealing over time. This resilience makes it suitable for high-traffic areas, such as kitchens and commercial spaces.

e3 edgeband

2. Moisture Resistance In environments prone to humidity, such as kitchens and bathrooms, E3 edgebanding excels due to its moisture-resistant properties. This characteristic helps prevent warping and deterioration, prolonging the life of furniture and cabinetry.

3. Chemical Resistance E3 edgebanding also offers resistance to a range of chemicals, making it ideal for environments where cleaning agents and other substances may come into contact with the edges of furniture. This feature is particularly beneficial for medical and laboratory settings.

4. Aesthetic Versatility Available in a wide variety of colors, finishes, and textures, E3 edgebanding allows designers to create cohesive and attractive designs. It can easily match or complement different types of materials, enabling greater creativity in furniture design.

5. Easy Application The installation process for E3 edgebanding is straightforward, allowing for efficient production and minimal material waste. Manufacturers can quickly apply the edgebanding to various types of panels, speeding up the overall manufacturing process.

Significance in the Furniture Industry

The significance of E3 edgebanding in the furniture industry cannot be overstated. It not only enhances the functional aspects of furniture but also elevates its visual appeal. As consumers increasingly seek durable and stylish products, the demand for E3 edgebanding continues to rise.

Moreover, the eco-friendliness of composite materials used in E3 edgebanding aligns with the industry's shift towards sustainable practices. Manufacturers can create high-quality products without compromising the environment by using recycled materials and low-emission adhesives.

Conclusion

E3 edgebanding is more than just a finishing touch for furniture; it represents a leap forward in technology and design standards within the industry. Its combination of durability, moisture and chemical resistance, aesthetic versatility, and ease of application make it a preferred choice for modern furniture manufacturers. As trends continue to evolve, E3 edgebanding stands poised to remain a vital component in creating beautiful, functional, and lasting furniture solutions. Whether in residential or commercial spaces, the impact of E3 edgebanding is sure to be felt for years to come.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025