edge banded

Understanding Edge Banded Products A Comprehensive Overview

Edge banding is a vital process in woodworking and furniture manufacturing that involves applying a thin strip of material to the raw edges of panels. This technique not only enhances the aesthetics of the furniture but also improves its durability and longevity. In this article, we will explore the significance of edge banding, the materials used, the methods of application, and the benefits it brings to the table.

What is Edge Banding?

Edge banding refers to the process where strips of material, often made of wood, plastic, or veneer, are affixed to the exposed edges of panels, such as plywood, particleboard, or MDF (medium-density fiberboard). The purpose is to conceal the unfinished edges and create a smooth, professional finish. Edge banding is commonly used in furniture, cabinetry, and interior fittings in both residential and commercial settings.

Materials Used in Edge Banding

Various materials can be used for edge banding, each offering different aesthetic and functional properties

.1. Wood Veneer This natural material provides an authentic wood appearance, making it an ideal choice for high-end furniture. It can be stained or finished to match the existing wood tones of the piece.

2. PVC Edging Polyvinyl chloride (PVC) edging is popular for its durability and availability in a multitude of colors and textures. It is water-resistant, making it suitable for kitchen and bathroom furniture.

3. ABS Edging Acrylonitrile Butadiene Styrene (ABS) is another plastic option that boasts excellent resistance to impact and wear. Its flexibility allows it to conform well to various edge profiles.

4. Melamine This is a cost-effective option that combines resin and paper, providing a consistent finish that can mimic laminate surfaces.

Methods of Application

edge banded

The application of edge banding can be performed using several methods, depending on the equipment available and the desired finish

1. Hot-Melt Adhesive This is the most common application method, where a hot-melt adhesive is used to bond the edge banding to the panel. The edge banding is then trimmed flush and sanded to create a smooth finish.

2. Iron-On Edge Banding A simpler method suitable for DIY projects involves using a household iron to melt the adhesive on the back of the edge banding, pressing it onto the panel edge.

3. Pre-Glued Edge Banding Some edge banding products come with an adhesive backing that requires no heat source. This makes application quick and straightforward.

Benefits of Edge Banding

The use of edge banding provides numerous advantages

1. Enhanced Aesthetics Edge banding adds a finishing touch to raw edges, improving the overall look of furniture and cabinetry.

2. Protection Against Damage It helps to seal the edges from moisture, dust, and physical damage, significantly prolonging the life of the material.

3. Cost-Effectiveness Edge banding is a relatively low-cost solution that allows manufacturers to use less expensive substrates without sacrificing quality or appearance.

4. Customization With a wide range of colors, textures, and materials available, edge banding offers limitless possibilities for customization to suit any design style.

In conclusion, edge banding is an essential element in the production of high-quality furniture and cabinetry. Understanding its materials, applications, and benefits can help manufacturers and consumers alike appreciate the craftsmanship behind their designs, leading to more informed purchasing decisions and ultimately, better products. Whether you are a DIY enthusiast or a professional in the industry, mastering the art of edge banding can significantly enhance your work.

-

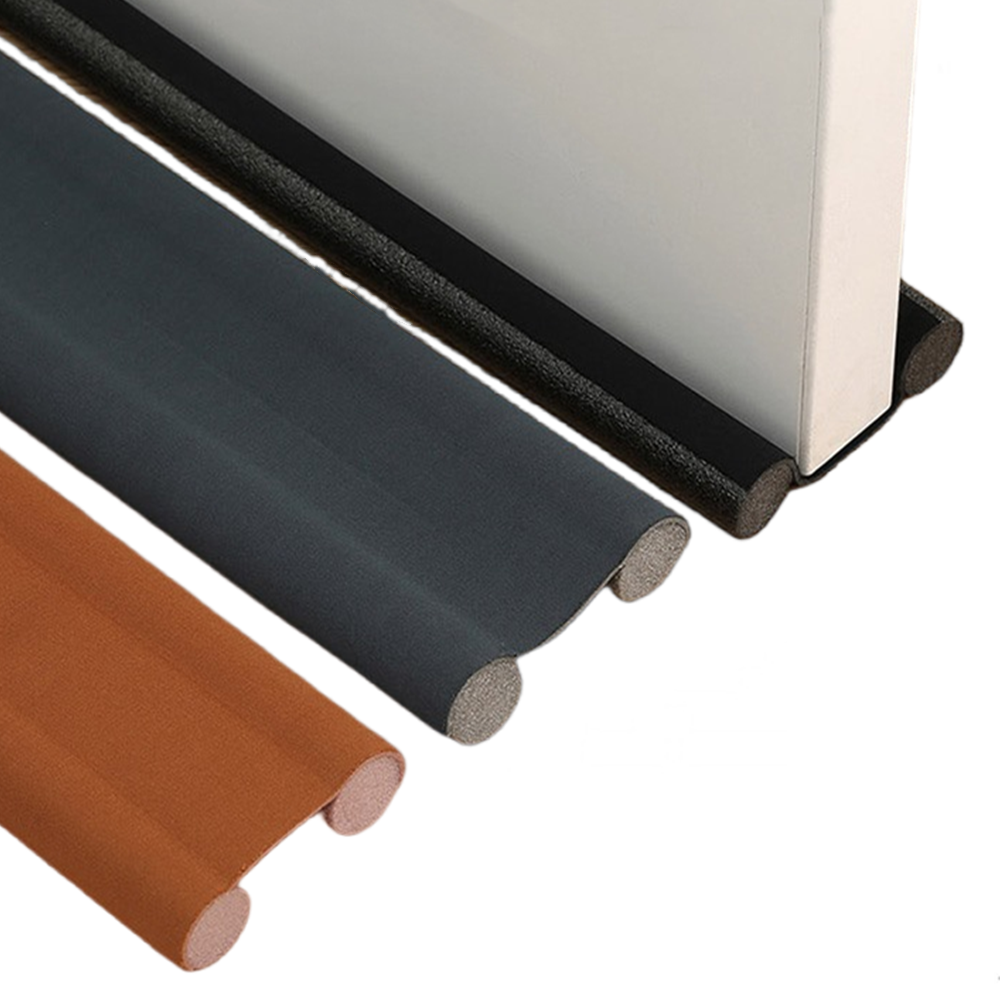

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025