edge banding pvc tape

Understanding Edge Banding PVC Tape A Comprehensive Guide

When it comes to modern woodworking and furniture manufacturing, the finishing touches make all the difference. One of the most crucial aspects of this process is edge banding, particularly with the use of PVC tape. This article will explore what edge banding PVC tape is, its applications, advantages, and how to effectively use it in your projects.

What is Edge Banding PVC Tape?

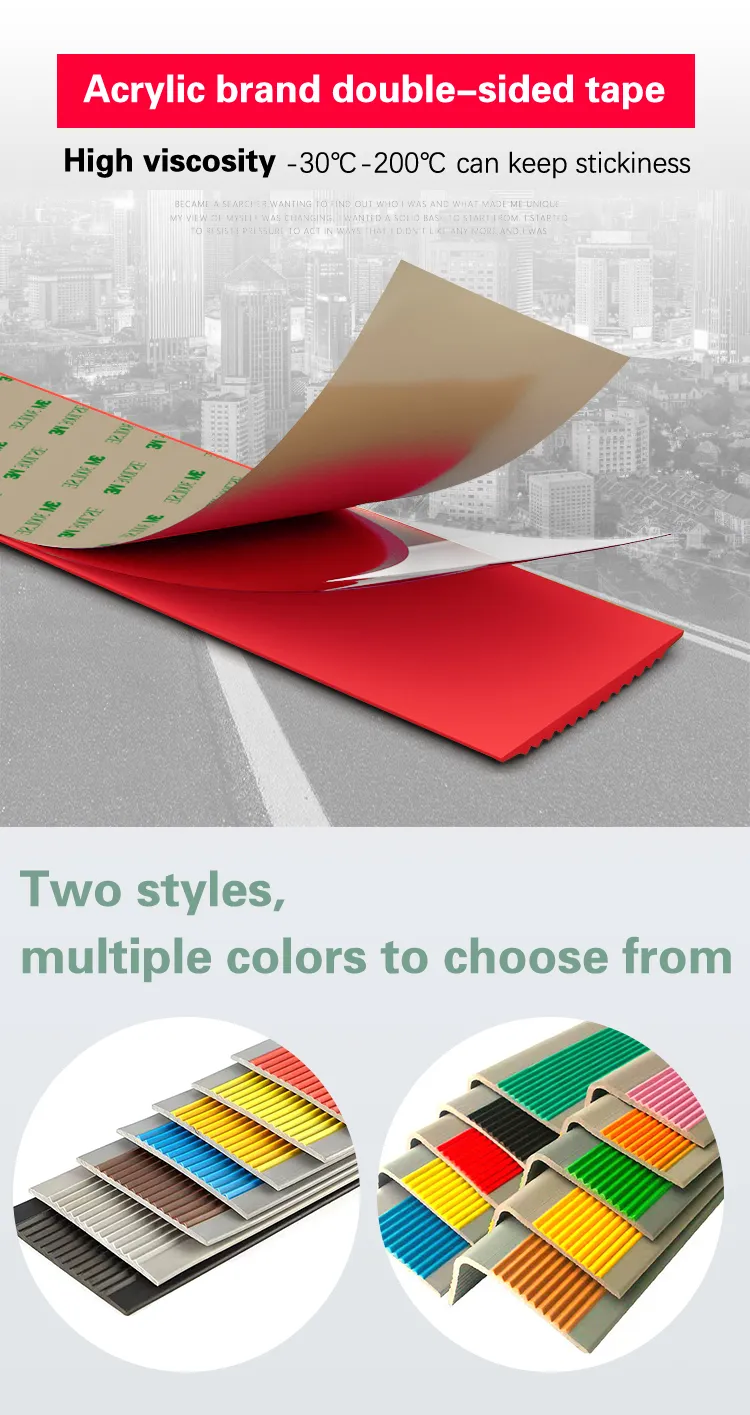

Edge banding PVC tape is a thin strip of polyvinyl chloride (PVC) that is used to cover the exposed edges of particleboard, MDF (medium-density fiberboard), plywood, or other types of substrates. The primary purpose of this tape is to provide a finished look and to protect the edges from moisture, wear, and damage. The tape comes in various thicknesses, colors, and finishes, allowing it to closely match or complement the surface of the furniture or cabinetry being produced.

Applications of Edge Banding PVC Tape

Edge banding PVC tape is widely used in various applications, including

1. Furniture Manufacturing From cabinets to tables, edge banding is essential for creating aesthetically pleasing and durable furniture. 2. DIY Projects Hobbyists and DIY enthusiasts use edge banding to achieve professional results in custom furniture and woodworking projects. 3. Cabinetry In kitchen and bathroom cabinetry, edge banding protects edges from moisture and enhances overall appearance. 4. Paneling Wall panels and other decorative wood applications benefit from the use of edge banding for a refined look.

edge banding pvc tape

Advantages of Edge Banding PVC Tape

1. Durability PVC is resistant to moisture and various chemicals, providing a durable protective barrier for the edges of boards. 2. Aesthetic Appeal With a wide variety of colors and textures, edge banding PVC tape can enhance the overall appeal of furniture pieces. 3. Ease of Application Applying edge banding tape is relatively straightforward, allowing for quick and efficient processing in both industrial and individual settings. 4. Cost-Effectiveness Compared to solid wood edgings, PVC edge banding is often more affordable, making it a cost-effective option for manufacturers and DIYers alike. 5. Smooth Finishes The use of edge banding provides a seamless appearance, reducing the likelihood of splinters and rough edges.

How to Use Edge Banding PVC Tape

Applying edge banding PVC tape can be easily achieved with the following steps

1. Prepare the Surface Ensure that the edge of the board is clean, smooth, and free from dust or debris. This aids in better adhesion. 2. Cut the Tape Measure the length needed for the edge you are covering and cut the PVC tape accordingly. It is recommended to cut the tape slightly longer than the edge to ensure complete coverage. 3. Apply the Tape Using an edge banding machine or an iron set to a low heat, apply the tape to the edge. If using an iron, carefully press the tape onto the edge while ensuring not to scorch the tape or underlying board. 4. Trim Excess Tape Once the tape is adhered, use a trimmer or a utility knife to remove any excess tape from the edges. 5. Finishing Touches Finally, sand the edges lightly to ensure a smooth transition between the tape and the substrate.

Conclusion

Edge banding PVC tape is an essential tool in the woodworking and furniture manufacturing industry, providing aesthetic value and functional protection to various substrates. Its versatility, durability, and ease of application make it a preferred choice among professionals and enthusiasts alike. Whether you are manufacturing high-quality cabinets or embarking on a DIY project, incorporating edge banding PVC tape into your workflow can significantly enhance the final product, making it more appealing and long-lasting. As you explore your next woodworking venture, consider the endless possibilities that edge banding can offer.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025