Exploring the Benefits and Applications of Edge Banding Strips in Furniture Design

Understanding Edge Banding Strips Importance and Applications

In the world of woodworking and furniture manufacturing, precision and aesthetics go hand in hand. One of the essential components that contribute significantly to both functional and visual appeal is the edge banding strip. Edge banding refers to the thin strip of material that is applied to the exposed edges of plywood or particleboard to provide a finished look and enhanced durability.

What is Edge Banding?

Edge banding strips are typically made from materials such as wood veneer, PVC, melamine, or acrylic. They are available in a variety of colors, patterns, and textures, allowing manufacturers to match or contrast them with the core material. The primary purpose of edge banding is to cover the raw, unfinished edges of man-made boards, which are often unattractive and prone to damage or moisture infiltration.

Importance of Edge Banding

1. Aesthetic Appeal Edge banding significantly enhances the visual quality of furniture. It allows for seamless transitions between different materials and finishes, ensuring that the overall appearance is polished and sophisticated. With a wide range of options available, designers can create visually striking combinations that elevate the design of cabinets, shelves, and tables.

2. Durability and Protection The raw edges of plywood or particleboard are susceptible to damage from impacts, moisture, and general wear and tear. Applying edge banding helps protect these vulnerable areas, extending the lifespan of the furniture. For instance, PVC edge banding is particularly effective as it is resistant to water, making it ideal for kitchen and bathroom applications.

3. Cost-Effective Solution Edge banding provides a cost-effective way to achieve a high-end look without the expense of solid wood or high-quality finishes. By using high-quality edge banding, manufacturers can offer attractive, durable products at competitive prices.

Applications of Edge Banding

edge banding strip

Edge banding strips are widely used in various applications across the furniture and cabinetry industries

. Some common uses include- Kitchen Cabinets In modern kitchens, edge banding is often applied to the edges of cabinet panels. It not only contributes to a refined look but also protects the underlying material from moisture and steam.

- Office Furniture Desks, filing cabinets, and shelves benefit from edge banding, ensuring a professional appearance while also withstanding the rigors of daily use.

- Retail Displays Retail environments often require furniture to be both visually appealing and durable. Edge banding can enhance the overall design of display units and shelving while ensuring they remain functional over time.

- DIY Projects Hobbyists and DIY enthusiasts can also utilize edge banding in their projects, providing a simple way to elevate the quality and durability of homemade furniture.

Application Techniques

There are various methods for applying edge banding, including hot melt adhesive, contact cement, and pre-glued options. Each technique offers different advantages, and the choice depends on factors such as the type of edge banding material used, the desired finish, and the equipment available.

Conclusion

In conclusion, edge banding strips play a crucial role in the woodworking and furniture manufacturing industry. Their ability to improve aesthetic appeal, provide protection, and offer a cost-effective solution makes them an indispensable component in creating high-quality furniture. As trends in design continue to evolve, edge banding will remain fundamental in achieving the desired look and longevity in various applications, from modern kitchens to stylish office spaces. Embracing the potential of edge banding not only enhances the physical attributes of furniture but also reflects a commitment to quality craftsmanship in woodworking.

-

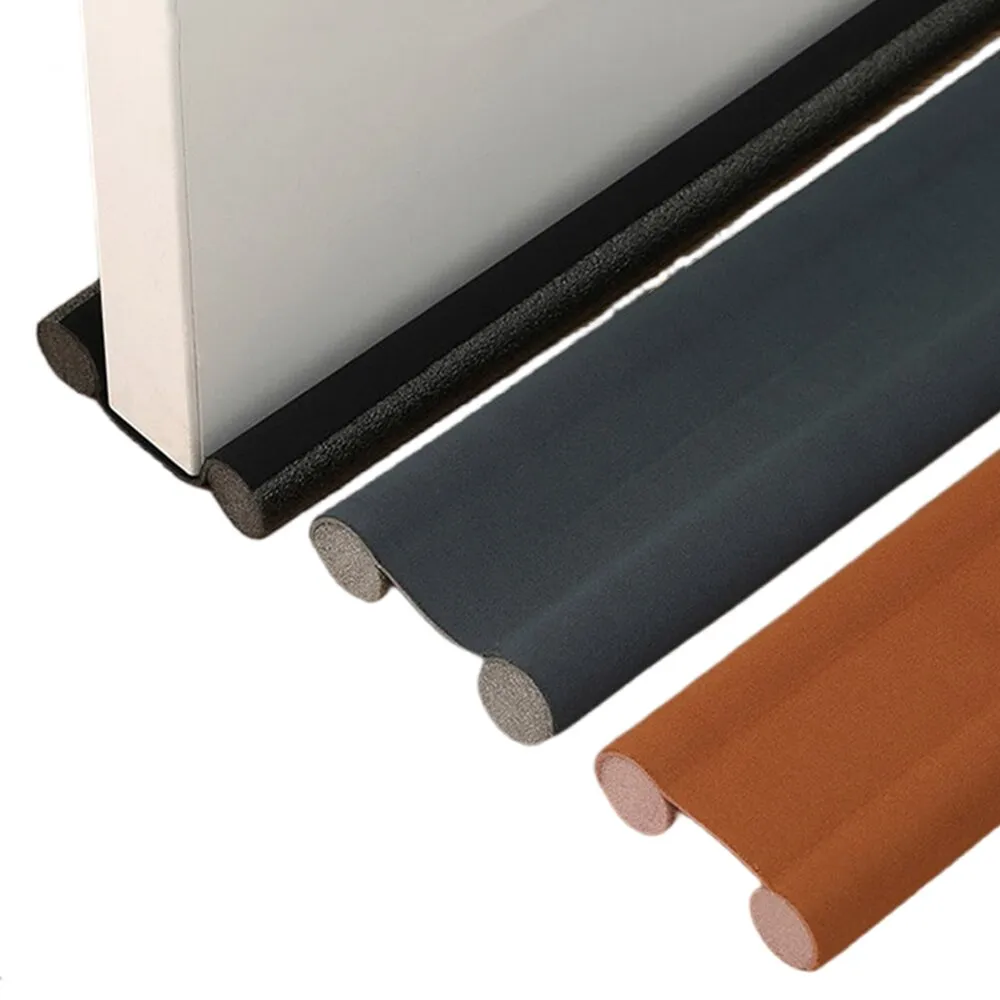

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025