edge banding tape

The Importance of Edge Banding Tape in Furniture Manufacturing

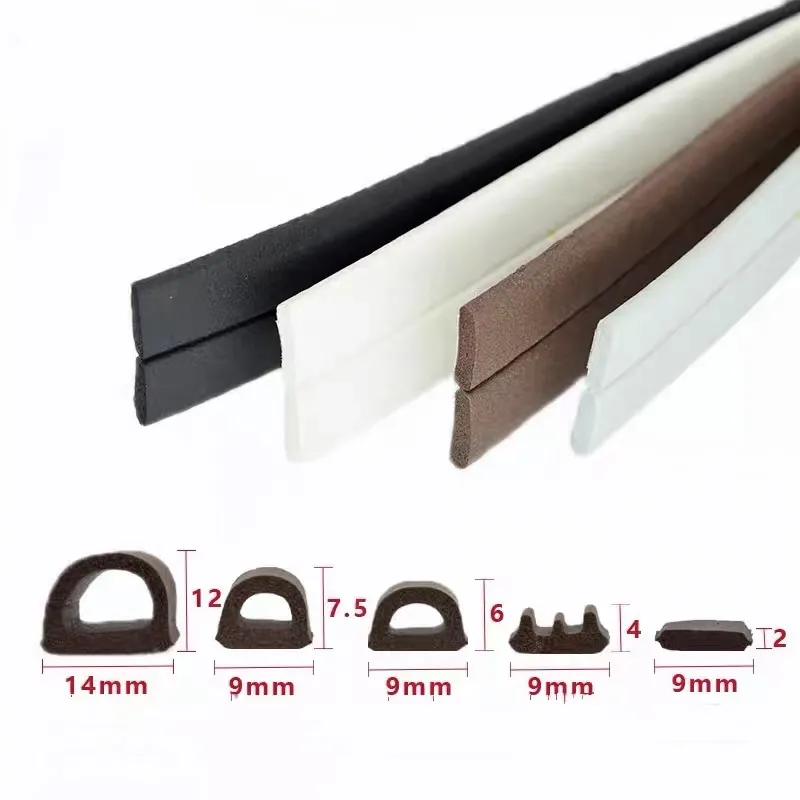

Edge banding tape is an essential component in modern furniture manufacturing, playing a crucial role in enhancing both the aesthetics and durability of various products. This specialized tape is used to cover the exposed edges of plywood, particle board, and other composite materials, effectively creating a seamless transition between the surface and its edges. As furniture design evolves, the significance of edge banding tape continues to grow, catering to design trends and consumer preferences for quality and appearance.

Aesthetic Appeal

One of the primary reasons furniture manufacturers use edge banding tape is to improve the visual appeal of their products. Exposed edges in unfinished materials can give a product a raw and unrefined look, which is often undesirable for consumers seeking polished and professional finishes. Edge banding tape comes in a variety of colors, textures, and materials, allowing manufacturers to choose options that complement the overall design. Whether it’s a sleek, modern look with high-gloss PVC or a warm, rustic appearance with wood veneer, the right edge banding tape can elevate the entire piece of furniture.

Durability and Protection

In addition to aesthetics, edge banding tape serves a vital protective function. The edges of furniture are particularly susceptible to wear and tear, including chipping, moisture damage, and deterioration over time. By applying edge banding tape, manufacturers can significantly enhance the durability of their products, ensuring that they withstand daily use and continue to look new for years. The tape acts as a barrier against environmental factors, thereby prolonging the life of the furniture and ultimately providing better value for consumers.

edge banding tape

Easy Application

The application of edge banding tape is relatively straightforward, especially with the advancement of modern machinery and adhesive technologies. Most edge banding tapes come with a pre-applied adhesive that makes it easy to bond to the edges of various materials. For larger manufacturers, automated edge banding machines streamline the process, allowing for precise and efficient application that reduces labor costs and increases productivity. However, for smaller workshops and DIY enthusiasts, manually applying the tape is also an accessible option, promoting versatility in its usage.

Sustainable Options

With a growing awareness of environmental issues, the demand for sustainable materials in furniture manufacturing has surged. Many edge banding tapes are now produced from recyclable or eco-friendly materials, which align with the values of environmentally-conscious consumers. Manufacturers looking to enhance their green credentials can select edge banding options that reflect their commitment to sustainability, thus appealing to a broader audience and meeting market demands.

Conclusion

In conclusion, edge banding tape is a small yet significant element in the furniture manufacturing process. Its ability to improve aesthetics, enhance durability, and promote sustainability makes it an invaluable resource for manufacturers aiming to produce high-quality furniture. As design trends continue to evolve, so too will the applications and innovations surrounding edge banding tape, ensuring its place at the forefront of the furniture industry for years to come. Investing in the right edge banding solutions not only elevates products but also provides consumers with reliable and visually appealing options that stand the test of time.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025