Understanding Different Sizes of Edge Banding Tape for Various Applications

Understanding Edge Banding Tape Sizes A Comprehensive Guide

Edge banding tape plays a pivotal role in woodworking and furniture making, serving not only a functional purpose but also enhancing the aesthetic appeal of finished products. When it comes to choosing edge banding tape, one of the most critical aspects to consider is the size. This article will delve into the various sizes of edge banding tape, their applications, and how to choose the right one for your projects.

What is Edge Banding Tape?

Edge banding tape is a thin strip of material applied to the exposed edges of particle board, plywood, or medium-density fiberboard (MDF). Its primary purpose is to cover these edges to prevent moisture absorption, provide a finished look, and improve durability. Edge banding is available in various materials, including PVC, melamine, and wood veneer, each offering distinct characteristics and finishes.

Common Edge Banding Tape Sizes

Edge banding tape comes in a range of sizes, typically measured in width and thickness. Below are the most common sizes you will encounter

1. Width The width of edge banding tape typically ranges from 0.7 inches (18 mm) to 3 inches (76 mm). The most common widths for general use are 0.75 inches (19 mm) and 1 inch (25 mm). The width you choose will depend on the thickness of the material you are covering and the desired aesthetic. Wider tapes often have a more substantial appearance, while narrower options offer a sleeker finish.

2. Thickness The thickness of edge banding tape can vary significantly, generally ranging from 0.4 mm to 3 mm. Thicker edge banding provides better durability and can withstand wear and tear more effectively. Conversely, thinner options may be used for applications requiring flexibility or a more subtle edge finishing.

Selecting the Right Size

edge banding tape sizes

Choosing the right edge banding tape size is crucial for achieving the desired results in any woodworking project. Here are some considerations that can help you make the right choice

- Material Thickness Measure the thickness of the board or panel that requires edge banding. Ideally, the tape width should match or exceed the board thickness to ensure complete coverage. Most professionals recommend a width that is at least equal to the material thickness.

- Finish The desired finish can influence your size selection. For a seamless look, opt for narrower tape that blends effortlessly with the surface. If you want to make a bold statement, wider tape may be the way to go.

- Application Method The method you plan to use for applying the edge banding can also affect your choice. Heat-activated tape may expand slightly when heated, so choose a size that accommodates this expansion. For manual applications, ensure that the width allows for excellent handling and adhesion.

- Aesthetic Preferences Personal style and the overall design theme of your project will guide your size selection. Consider how the edge banding will complement the colors and materials used in your project.

Conclusion

In woodworking and furniture manufacturing, understanding the various sizes of edge banding tape is essential for achieving both functional and aesthetic goals. By considering the width and thickness of the tape, you can ensure that your edges are well protected and visually appealing. Take the time to assess your project's requirements, and carefully select the edge banding tape sizes that align with your vision. Whether you're a seasoned professional or a DIY enthusiast, the right edge banding can elevate your work and create beautifully finished furniture that lasts for years to come.

Edge banding tape is more than just a finishing touch; it's a critical component that can significantly enhance the quality and durability of your woodworking projects. Choose wisely!

-

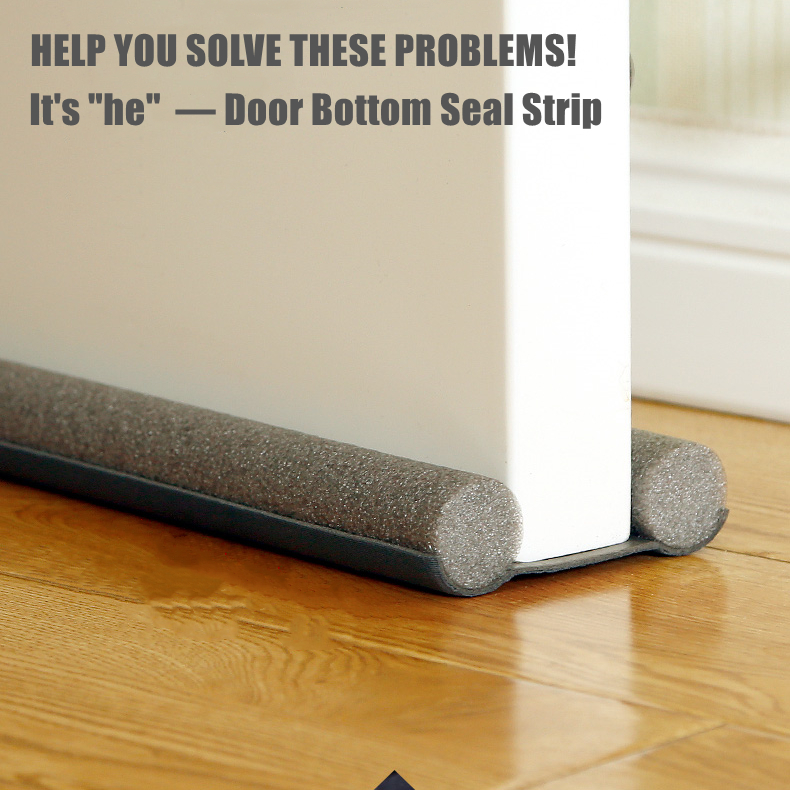

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025